A natural diamond is an incredibly beautiful, very hard and durable stone that gives an unsurpassed shine. But at the same time it is also very expensive. Synthetic diamonds are much more common than regular diamonds made by nature. The fact is explained by the fact that in nature there are imperfect stones, with defects, their sizes are far from ideal. In laboratory conditions, it is possible to create artificial diamond for jewelry, electronics, medical equipment and industrial needs. Of course, the technology is complex and financially expensive; scientists have been developing a satisfactory method for decades.

How did synthetic diamonds originate?

Artificial diamonds

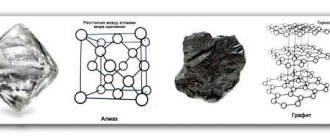

The history of the emergence of synthetic minerals dates back to 1797. It was then that scientists began to study the structure of natural materials and found out that diamond consists entirely of carbon. But it was not possible to produce carbon using production facilities. Therefore, work has not progressed from theory to practice in creating an artificial mineral.

The possibility of creating a solid element in the laboratory was again discussed in 1926. A team of French scientists came closer to the truth, but they failed to make a stone that would satisfy in appearance and be correct from the technical side of the issue. The problem was that the crystal lattices of the durable mineral could not be transmitted using the equipment of that time.

In 1942, the patent for the research was acquired by General Electrics. Despite the turbulent military situation, the company began thorough research. Experts have found that the necessary technical characteristics can be imparted to a substance only at high pressure and by raising the temperature. They created laboratory conditions unprecedented for that time: pressure of 5 hPa and heating to 3 thousand degrees Celsius. The first diamond, which had detailed parameters for the strength of light refraction and structure, was created only a decade later - in 1951.

Scientists synthesize artificial diamonds

Three years later, a company with technology for producing artificial diamonds enters the market. It was not possible to use stones in jewelry, since the sizes of the artificial components created were small. But industrial and even military firms became interested in them. Artificial diamond has also begun to be used for the production of medical equipment.

It was possible to solve the problem with miniature sizes only by 1970. Stones began to be produced in sizes larger than 1 carat, which was enough for jewelers to start making jewelry with artificial stone inserts.

Worth knowing! Now hundreds of companies around the world are engaged in the production of diamonds in laboratory conditions. They produce diamonds of various sizes, shapes, and interesting color palettes. The largest specimen, which was grown artificially, measures 34 carats. It is listed in the Guinness Book of Records.

Fashion trends

The diamond has attracted people for a long time, which is why it was just as often imitated in the past as it is now. Previously, diamond was replaced with zircon, spinel, crystal, and rutile.

Synthetic stone analogues are an independent area of the jewelry market. The fashion for laboratory samples is growing from year to year in accordance with the ideology of responsible consumption. Since the production of laboratory crystals causes less harm to the environment, more and more buyers want to own such jewelry.

Features of artificial diamonds

An artificial diamond cannot be called a copy; from a physical point of view, this is incorrect. The fact is that diamonds made by nature and by human hands are identical in their indicators, in particular, hardness on the Mohs scale, refractive index of solar rays and other parameters. They differ in that they are produced in different ways. Diamonds retain the properties of a natural nugget. In particular, the characteristics are identical:

- strength;

- shine;

- structures;

- textures;

- refractive index of solar rays;

- nominal weight;

- resistance to electric charge;

- ability to conduct heat;

- elasticity;

- melting temperature, etc.

Of course, in laboratory conditions it is possible to produce stones free of defects. The material obtained is identical to what nature could create under the best conditions. Only 20% of the total number of nuggets mined in world production are used in jewelry. The rest have inclusions, defects, and a cloudy surface, so they are used for technical purposes only. This explains the fact that artificial diamonds in most jewelry products and devices have long been replaced by artificial analogues.

An artificial diamond is called by different names. Scientists divide copies into so-called HPHT minerals - their production requires exposure to high temperatures and pressure; CDV stones, the production of which uses vapor deposition of chemical elements. Growing diamonds is also possible using other technologies - the types obtained are moissanite, rhinestone, cubic zirconia, fabulite, rutile, cerussite and others. The synthetic diamond obtained in this way is not a true copy, since it does not completely copy the characteristics. A common misconception concerns the cubic zirconia stone, which even an experienced jeweler cannot distinguish from a diamond by its appearance.

Brooch in the shape of a turtle, decorated with cubic zirconia

How does a synthetic diamond differ from natural stones?

Synthetic diamond has identical characteristics. The indicators are the same, in particular:

- Chemical formula - carbon 100%

- Refractive index - 2.42

- Variance - 0.044

- Hardness - 10 (the highest point on the Mohs scale)

- Density - 3.52.

As can be seen from the list, the characteristics of a real diamond and a natural diamond are indistinguishable. But, an artificially grown diamond is obtained in a few hours or days, while a natural mineral will take hundreds of years to form.

Externally, only an experienced jeweler can distinguish an artificial diamond from a real one. On the left is real stone, on the right is synthetic.

Creating synthetic materials for jewelry is a lucrative industry. The cost of an unnatural diamond can be higher than one created by nature if it is huge. Natural stones are inferior in appearance, as they have cracks, chips, and clouding. At the same time, no matter what the name of an artificial diamond is, it has the following features:

- there are no slightest inclusions or unevenness in texture;

- there are no cracks inside the stone that distort the passage of the sun's ray;

- the color does not fade over time.

An artificial diamond is unpretentious. If products with natural stones need to be periodically sent to salons for cleaning, then making a stone made in a laboratory sparkle is a matter of a few minutes. You will need to choose an available cleaning product with any level of abrasiveness and thoroughly rub the stone.

Rings and earrings with artificial diamonds

Methods for growing synthetic diamonds

A man-made diamond is called a stone that does not require many steps to produce. However, strict laboratory conditions must be observed. Fluctuations of even a hundredth of a degree in temperature will lead to disastrous results.

The technology in demand is under the influence of pressure and high temperature. The material – crystalline carbon – is placed in a vessel and then placed under a press. Water is supplied to the grate with a strong stream. It acts on crystalline carbon under high pressure. To further increase this figure, refrigerants are added. The pressure increases 10 times and reaches 5 hPa.

After reaching the required pressure, an electrical bus is connected to the crystal lattice. Current is supplied through it. As a result, the material heats up quickly. Graphite turns into a solid stone. At the final stage, the structures are defrosted and the liquid remaining from the refrigerants is drained. Artificial diamonds are removed and further processed.

The process of making artificial diamonds at a factory

Growing diamond with methane

Growing diamonds with methane is an affordable technology. Its use is not difficult, but safety rules must be followed. Methane technology is a method in which a crystal of artificial stone is obtained under the influence of an explosion of a substance.

A methane explosion leads to disruption of the integrity of the carbon lattice. The artificial diamond grows, the procedure is repeated again. No special temperature requirements are required.

There are several methane explosion technologies. The first is that an impulse push occurs. There are a lot of stones, but they are small in size. The second method is that the diamond is blown with methane at a temperature of 1100 degrees Celsius. The second method is expensive and requires laboratory conditions. But the result is a stone of any size, which is sold at a bargain price.

Color range of laboratory stones

Gas colorless diamond is a popular option. It is these stones that are more valuable in the jewelry market. But the difficulty is that it is more difficult to grow a transparent diamond than others. It requires effort and strict adherence to temperature parameters during production.

Transparent diamonds are obtained only if boron or nitrogen is not present in the original composition. Even the smallest ingress of chemical elements into the composition leads to tarnishing. This is not uncommon, which is why diamonds that are completely clear are the most expensive. They sell at a price identical to natural diamonds. Specimens from 1 carat are valued.

Synthetic colorless diamonds

Blue diamonds are produced by adding the element bromine to the crystalline carbon lattice. If a minimum of it hits, the finished diamond acquires a slight bluish tint. With a large ratio, the resulting stones have a bright blue tint.

Gold earrings with synthetic corundum and diamonds

Yellow, unnatural diamonds are produced by adding nitrogen. Receiving on the company’s equipment takes a minimum of time, so such options do not have a high price. You can make lemon, orange, yellow, sand variations.

Engagement ring with synthetic yellow and clear diamonds

Recently, black diamonds have begun to be created in production. They look interesting and are suitable for stylish jewelry. In the form of inserts they are used for rings, earrings and necklaces. Nickel is used during the production of black diamonds.

Black diamonds created by synthesis

Tips for home experiments

To increase the likelihood of successfully creating a diamond with your own hands, you will need to follow some recommendations:

- take distilled water - there should be no impurities in the liquid;

- When working with chemicals, you must use gloves and special utensils;

- the laboratory filter can be replaced with gauze, cotton wool or paper;

- the water for the solution should be warm, but not very hot;

- in the room where the container will be placed, a constant temperature must be maintained, without sudden changes, otherwise the crystal will grow quickly, but will be fragile;

- when adding a new solution, its temperature and the temperature of the main one must be the same;

- When growing transparent crystals, you should not rush - with accelerated growth they become cloudy.

Synthetic jewelry stones have all the advantages of natural analogues. Moreover, laboratory-produced diamonds have even greater hardness and purity. Scientists have not yet come up with inexpensive and accessible ways for everyone to obtain gems at home, so jewelry lovers can grow beautiful multi-colored crystals from salt or sugar solutions and create their own collection from them.