General rules for cutting stones

Several of the first cutting techniques appeared in the 19th century; it was then that jewelers decided on the standards of the techniques. In addition, fantasy varieties appeared.

It depends on the type of cut:

- The cost of a diamond. Always a complex cut with a large number of facets will cost more than standard cutting methods.

- The appearance and brilliance of a diamond. With the help of cutting, you can hide the defects of the stone and its unevenness. But this can only be achieved if the jeweler is highly skilled.

Often, diamond cutting is done ineptly, then the stone is considered damaged and is sold cheaper. The edges should be smooth and refract light in such a way that, looking through the stone at the sun, you can see the rays from the edges directed to one point. In this case, the refracted ray has the colors of a rainbow.

The first geometric calculations were carried out by Marcel Tolkowsky: it was he who determined the parameters of an ideal round diamond, which is now a common process technique. Such a stone has 57 or occasionally 58 facets. This can be done by a jeweler using the following techniques: Tolkowsky, Johnson and Roech, Eppler and the Scandinavian diamond cut.

As a result, the diamond has the following parts:

- crown - the upper part of the stone with a platform;

- pavilion - cone-shaped lower part;

- calleta - the top of a stone;

- girdle - the part between the crown and the pavilion.

Moreover, jewelers calculate the parameters of each of them, and if they do not coincide with the standards, then the cut is incorrect. But such methods are used only in standard cases.

Split

The first stage of diamond processing is its splitting. Of course, it would be interesting to get the stone as large as possible and not split it at all, but this can entail high brittleness if there are multiple inclusions or cracks. Previously, splitting was done using a chisel and a hammer after careful calculations by the master. But this often led to errors, and the stone could be damaged.

Recently, sawing has begun to be used instead of splitting. For these purposes, a diamond saw blade is used, consisting of chalk and covered with precious stone chips. This blade rotates at a speed of 10 thousand revolutions per minute and gradually cuts the diamond.

The process can take a very long time; one stone weighing 1 carat can take up to 8 hours to cut. But recently an even more reliable method has appeared - now a laser is used for these purposes.

Friction - This procedure produces the rough shape of the diamond. Two diamonds are fixed on a lathe or special installation, after which they are installed in the correct direction and rub against each other.

Types and classifications of cuts

There are situations when a jeweler comes across a diamond of an unusual shape. Then the fancy cut comes to the rescue

Common techniques:

- Stepped, in which the edges of the stone are parallel to the girdle and have a rectangular shape. Using this method, you can emphasize the purity of the stone.

- Modified - a fantasy option, which results in stones of different shapes.

- Mixed is the most popular technique after the round classical cut. People call her "Princess". It has a square shape with sharp corners and emphasizes the transparency of the stone and its shade. This stone looks like a pyramid. Since the lower part of the pavilion is quite massive, the entire play of light takes place there, which gives the mineral sophistication.

If we talk about the modified cut, it is popular due to its unusual shape, which is obtained in the end. With such products you can surprise others and express your individuality. These forms are also used in cases where it is necessary to display the purity of the stone as fully as possible.

Common fantasy forms

Round diamond

Of all the cut shapes, round diamonds are the most popular, perhaps due to their strong “play” and greater return of white light to the observer than other cuts. When creating a round cut, the yield from a diamond is significantly less than in the case of other cuts. This, along with the high popularity of round diamonds, are two main reasons for the relatively high cost of these stones.

The round cut sets the standard for other shapes and accounts for over 75% of all diamonds sold to date. This 57 (58)-sided shape consists of a crown (top), girdle (widest part) and pavilion (bottom). To achieve maximum play in a round diamond, certain proportions must be strictly maintained.

There are several types of cuts for the standard round stone shape.

Designations are recognized throughout the world :

- Type A. has an ideal cut in terms of the appearance of the stone. All parameters are taken into account. But at the same time, the method is uneconomical, and losses during the process amount to about 60% of the starting material. Accordingly, in stores, a cut stone according to this principle will be the most expensive. The area on the crown is formed by the intersection of squares.

- Type B. The stones are stretched in diameter or height, which affects their site. Rectangles intersect on it, not squares. Losses with this option are 48-55%.

- Type B. Minerals with poor symmetry, but the loss of raw materials is only 45%.

Of course, in addition to the price, this also affects the appearance of the stone. It won't play as much in the light. But at the same time, few non-professionals will be able to determine the type of cut.

The final cost depends on the type of disproportionality: in height, diameter or in all edges. Disadvantages of the cut can also be hidden by the setting of the stone, which should be made more massive.

Marquis

Marquise is a boat-shaped wedge cut. Awnings are often chosen by women who have an independent style. This elongated shape creates the effect of long and narrow fingers.

The cut dates back to the time of the Sun King, Louis XIV. The king, who wanted to marry the Marquise de Pompadour, ordered the creation of a diamond similar to the Marquise's smile. The cut looks impressive in solitaires, as well as surrounded by small diamonds.

Pear

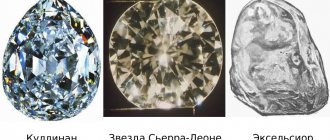

Pear is a drop-shaped wedge cut. These attractive diamonds are often used in pendants and earrings. Many of the largest stones ever found were cut into pears. Both large and small diamonds are cut in the shape of a pear. A large single pear-shaped diamond set in a ring visually lengthens the fingers.

Oval

Oval is a wedge cut with an oval outline. More often, this form is used for cutting large diamonds for setting in rings, earrings and pendants. A large single oval-shaped diamond set in a ring visually lengthens the fingers.

Princess

Princess – wedge cut square or rectangular with sharp corners. The cut has a very good game and a high degree of brilliantness.

This relatively new cut with many sparkling facets is often used as single pieces in rings, earrings and pendants. Often the princess in rings is accompanied by trilliants on both sides. To increase the play of the stone, it is necessary to significantly increase the depth of the pavilion to 70-78%.

While most square and rectangular cuts cannot match the sparkle of a round diamond, the Princess was specifically designed to approximate the sparkle of a round diamond.

When purchasing a princess cut diamond piece, you need to ensure that the setting protects the four corners of the stone that are most susceptible to chipping.

Emerald

Emerald is a stepped rectangular cut with truncated corners and has an octagonal outline. A diamond cut with emerald can be absolutely magnificent. This cut has less play, but wider and brighter flashes of light. Refined and elegant, this shape is often used to set rings.

Due to the “openness” of the cut, cracks, low color and poor cut quality become noticeable even to the naked eye, so when purchasing an emerald-shaped diamond, it is extremely important to pay attention to the quality of the stone.

The emerald cut diamond cut is not as traditional as the round cut and not as fashionable as the princess cut, which makes the price of emerald cut diamonds not as high (compared to other cuts). In recent years, square emerald cut diamonds have become more popular.

Asher

The Asscher cut is a type of emerald cut that has a square shape and more tiers. The usher allows the wearer to look elegant and majestic.

This Art Deco cut style combines old-fashioned charm with modern cutting technology to create a dazzling diamond. Ashers with equal length and width are preferred. This ratio should not exceed 1.1:1.

Radiant

This is a square or rectangular wedge cut with an octagonal outline. Radiant combines the elegance of emerald with brilliant and the play of a round brilliant. To achieve greater play of the stone, it is necessary to increase the depth of the pavilion during cutting, which in turn entails an increase in the weight of the stone.

The radiant cut is more often used for cutting single large stones. The radiant form can enhance the color of fancy colored diamonds.

How diamonds are cut

Yes, yes, dear reader. “Zvezdochka” is not only known for steamships. Since the beginning of the 2000s, the company has launched production of cutting rough diamonds into polished diamonds. As many probably know, a diamond, with all its other technical advantages, only becomes “the girl’s best friend” when it turns into a diamond. Today's photo report tells us about the path he will have to go through.

It all starts... You guessed it with a hanger. Third-party visitors who have passed the hard materials processing station (as cutting is officially called) are asked to put on a robe and are assigned at least two accompanying persons: a workshop worker who acts as a tour guide and an employee of the economic security department. Trust, as they say, but verify.

Now we are ready to get acquainted with the workshop. The first point on the route is a storage room for raw materials.

This is where the raw materials—uncut diamonds—come. Here they are processed: they are counted, weighed, checked for compliance with shipping documents, each stone is entered into an electronic accounting database and a unique route map is written out for each stone. In this route map, folded into an envelope, the diamond will travel through the areas.

From the storeroom, the diamond goes to the UZTC - a section of a closed technological cycle. Here technologists will sort and mark the stones.

This is done using a computer markup system. The installation scans the diamond and forms its three-dimensional digital model. Using this model, the technologist will decide how many diamonds will come out of a particular stone and what shape they will have. The principle of combining the value of the future diamond and minimizing waste is at the forefront. The program not only allows you to visualize the diamonds hidden in the diamond, but also gives their approximate value. The classic KR-57 cut usually has the highest cost. Unfortunately, not every natural stone allows you to achieve exactly this shape with maximum use of raw materials. The cost of this diamond placer is $3,560.

This stone will produce one diamond, but larger. Its cost will be just under three thousand dollars.

And of this - two, but smaller and, accordingly, for a more modest pocket.

Before leaving the site, the stones are glued onto special mandrels for subsequent processing. This rack is heated in an oven so that the glue holds the diamonds securely.

From the UZTTS the stones go to the sawing and peeling area. In the old days, sawing stone was done mechanically using a bronze disc coated with diamond.

Today, the majority of sawing is done with a laser. The installation operator has the ability to visually monitor the process.

Laser cutting, firstly, is faster. The sawing process, depending on the size of the stone, can take from five minutes to half an hour. Secondly, the laser cut thickness is only 2 microns, which significantly saves rough diamonds.

However, some stones that have high internal stress are dangerous to cut with a laser. And then sawing is carried out the old fashioned way - with a bronze disc.

After sawing, the diamonds, each of which is packed in a separate sheet-envelope with a bar code, a list of all operations carried out with the stone, the names of each of the workers whose hands touched the stone, and other information, are sent to the cutting department. This is where the diamond will turn into a diamond.

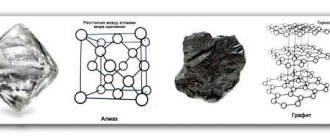

Diamond cutting is carried out on a rotating cast iron disc coated with diamond. When exposed to the mechanical action of a grinding disc, carbon changes its structure. A thin graphite film is formed on the crystal, which wears off, bringing the diamond to the desired shape.

The diamond is fixed into the seat of a special hand-held device - a collet.

Using adjusting screws, the cutter changes the position of the stone in the collet so that the diamond rests on the disk at the desired angle. This is how a shapeless stone acquires a platform, edges and wedges.

It also happens that the stone falls out of the collet mount. The rotating disk can send it on a “journey” around the area. Then the command “loss” is heard and the unlucky cutter goes in search of the lost diamond. Despite the fact that each cutter's place is equipped with special stone catchers, it happened that the search took a very long time.

In general, when the signal “loss” is signaled, the entire production turns into a “submarine”, from which, as you know, you can’t escape. Exit outside the site is stopped while searching for the lost stone. In the entire history of the work, only one diamond was considered completely lost. But he was found too. Having flown out from the cutter’s disk, the stone “stuck” to the wall, where it was discovered only a few years later.

After cutting and washing, they are no longer diamonds, but polished diamonds are delivered to the evaluation area. Here, specially trained, certified workers will evaluate the quality of the cut - the color and imperfections of the stone.

When grading, cut stones are compared to these standards.

The color and imperfections of a stone are almost the decisive factors in its price. The price of stones of similar weight and cut, but different in color, can differ significantly.

From the evaluation site, the diamond, through another storeroom, is sent far away - to the Smolensk Gemological Center. In Smolensk, the diamond will receive a certificate and turn into a commodity. It can be legally sold, given as a gift, passed on by inheritance, or simply “languished” over it, like Pushkin’s Koschey over gold.

The cost of this certified diamond is about one and a half million rubles.

All movements of stones outside the workshop are carried out by special communications convoys. Inside the workshop, control over the movement of stones is carried out by the economic security department of the enterprise security service. The accounting of stones is organized in such a way that even after many years it is possible to completely restore the history of each of them. Where it was mined, how and by whom it was purchased for processing, who and when touched this stone, what manipulations were performed with it, where at a particular point in time this stone was located while it was at the factory.

You can count the number of diamonds yourself. And each with its own detailed history.

Some diamonds cut at Zvezdochka are sent to Gokhran, replenishing the country’s gold and foreign exchange storehouses. Others become luxury items. The latter depart to the jewelry production areas located here in the workshop.

Jewelry production is technologically closely related to cutting. Gold, silver, rings, earrings, rings, pendants... Yes, yes. We have them too.

The production of serial jewelry begins with waxing.

In special rubber molds, the worker casts wax “prototypes” of future rings or earring parts. A casting mold is assembled from these wax blanks. Here it is called “herringbone”. The blanks are glued to the wax rod one to one, like branches on a Christmas tree. The collected wax tree is sent to the foundry area. Here it is filled with a molding mixture, mainly consisting of gypsum with special additives, and placed in the oven for several hours. The casting mold - flask - hardens, the wax is melted out of it, leaving an empty space of the desired shape.

Molds for custom-made piece jewelry or new designs are made on a special milling machine. Here the machine cuts them out of wax according to the loaded 3D models. The customer has the opportunity to “touch” the product before it is made in metal.

At the next stage, the plaster mold will be filled with gold alloy. Precisely an alloy. Alloying additives are introduced into gold of the 999th standard, bringing it to the “commercial” 585th standard.

Everything happens in this foundry furnace.

Ship steel comes to the plant in sheets, and jewelry gold comes in kilogram bars. It looks like a pure chocolate bar.

An ingot is a practical form for storing and transporting gold, but handling ingots is inconvenient. On this machine, gold entering jewelry production is rolled into strips into gold foil.

Later, when issued from the warehouse, this foil is cut by weight using ordinary scissors by a cutter, in accordance with the tasks for the production of specific jewelry.

The resulting casting is also a “herringbone”, only gold.

Blanks for future decorations are bitten off from this “Christmas tree”.

Finished castings are inspected for the integrity of the casting, the presence of cavities and defects. After this control step, assemblers will clean and assemble the workpieces into finished products. Here the diamonds will be set on the jewelry.

The assembler is working on the pallet. Gold dust, crumbs and scraps - they are called “cuts” - are collected in special containers, separated by the color of the metal - white, yellow, red.

Once a month, assemblers melt down these saw cuts and, after examination, they are returned to production.

This is what recast saw cuts look like.

The examination is carried out here using the clever X-MET 7500 device.

The device determines the purity of gold and the composition of impurities in the metal. In this case, the cast saw cuts contain gold and alloys - copper, nickel, silver, zinc and tin. For specialists, this is an X-ray fluorescence portable energy dispersive spectrometer. We did not dare to find out the principle of its operation, but a curious reader can easily google the necessary information. In the layman's interpretation, it is an analyzer of the chemical composition of a metal.

The device, despite its compactness, is very expensive. It costs even more than the diamond mentioned above. The root part of the golden “Christmas tree”, called “pyatak” or “heel”, has a different fate. A lot of impurities and dirt collect in this lower part of the casting. This gold will be purified at the refinery.

From the assembly area, the jewelry goes to the polisher.

Here they will be given their final shine and sent to the warehouse. From there it's on to the store.

Like diamonds and diamonds, each gold piece of jewelry “travels” through the technological chain in a separate package, equipped with a label with a bar code that allows you to trace the entire history of a particular ring, tie clip or some other expensive trinket.

This concludes the story. We hope you found it interesting. We thank the deputy heads of the workshop Olga Borovkova and Alexey Kozhin for the cordiality with which they received us and the fascinating story.

Source