Jewelry stones and gems are valued for their transparency, ability to refract light, or for their beautiful colors and intricate patterns in the case of opaque minerals. However, looking at samples extracted from the rock, it is difficult to see the beauty hidden inside. To show and emphasize the advantages of gems, the mined raw materials are subjected to additional grinding, polishing or cutting. It is stone processing that allows you to reveal the best properties of natural raw materials and increase their value.

What is stone refining

Natural minerals with high levels of transparency and rich color are very rare. Most of the mined raw materials have minor defects, uneven or pale color. To improve the quality and characteristics of jewelry stones, methods for refining them have been developed. Unlike natural gems, refined samples are cheaper. Moreover, the accompanying documents must indicate whether the mineral has been refined.

Refining is the processing of already cut crystals or natural untreated stone

It consists of a targeted physical and chemical effect on raw materials, as a result of which it is possible to achieve an increase in the key consumer qualities of minerals.

For example, jewelers have noticed that by heating clear or lightly colored amethyst crystals, which have a low market value, they can produce sought-after yellow stones that resemble citrines. Minerals with zonal coloring, called ametrines, have become popular: when amethyst is heated from just one side, the resulting crystal is yellow at one end and purple at the other.

The main methods of refining stones that are accepted in the jewelry industry and are considered acceptable:

- Annealing (heat treatment). As a result of exposure to high temperatures, many minerals acquire a more saturated color. This method is also used to remove unwanted tints (such as blue in rubies) or inclusions (such as rutile in sapphires).

- Oil treatment - used in cases where it is necessary to hide cracks. The refining process consists of injecting oil with a similar refractive index into the split, from which air and water have been pumped out. As a result, the cracks become almost invisible.

- Treatment with epoxy resin , like oiling, improves the transparency of samples and increases their strength.

- Radioactive irradiation is the main method for producing naturally occurring blue topazes, colored diamonds and quartz. Depending on the type of mineral, X-ray, ultraviolet, gamma radiation or exposure to a flow of energetic particles (neutrons, protons, electrons or alpha particles) is used.

- Coating allows you to obtain crystals with an unusual color, for example, after applying a thin film of precious metals to the surface of topaz, you get mystic topaz, characterized by iridescent tints.

Why do minerals need to be processed?

As already mentioned, natural specimens are not as beautiful as processed ones. Someone is ready to argue with this, believing that nature knows its business, and if it creates gems like this, then there is a reason for it. It is possible that this is so, but still the majority prefer refined minerals to natural ones, which are more suitable for amateurs. Among the reasons why a mineral should be refined are the following:

- Aesthetics. The process of refining results in an improved appearance of the breed. The gem becomes visually cleaner, brighter, acquires a more saturated shade, which, moreover, is also durable.

- Benefit. Undoubtedly, there are natural gems of amazing beauty that no one would even think of processing. But such breeds are incomparably more expensive than their ennobled counterparts.

- Popularity. Thermal, chemical or mechanical treatment allows the crystal to “open up” to its fullest and demonstrate its amazing beauty. In addition, each mineral has unique properties. This allows any person to choose exactly the stone that suits him in all respects.

Types of stone processing

Refining stones is just one of the stages of processing gems, which is not mandatory. Before falling into the hands of a jeweler and becoming part of a piece of jewelry, all jewelry stones go through a mandatory processing process. Its methods are selected depending on the basic physical and chemical properties of the mineral: transparency, hardness, presence or absence of a pattern.

Modern processing includes the following methods:

- Rock cutting is carried out on machines equipped with band, circular or cable saws. As an alternative to industrial sawing of mined rock, a laser is used for this purpose.

- Peeling - giving raw materials a preliminary shape.

- Grinding is an intermediate step that allows you to obtain a uniform surface roughness of the stone and better evaluate its shape.

- Polishing - reveals the pattern and structure of the mineral, for which grinding wheels are used with a coating of grinding powders.

- Cutting , together with previous methods, is an integral part of the processing of transparent precious stones, as a result of which it is possible to fully reveal the brilliance and light refraction of minerals.

- Polishing is the final stage, as a result of which the surface of the stone acquires a mirror shine.

- Engraving is a decorative processing option that consists of applying a design to a surface.

Application of different methods to certain types of gems

Refining stones is a fascinating and interesting process. When carrying out it, you must have certain knowledge so as not to damage the structure or spoil the color irrevocably. Below we describe how some minerals can be refined.

Table 1. “Methods of refining precious stones”

| Method | Stone |

| Regular dyeing or bleaching | Agate, pearl, coral, black onyx |

| Heat treatment | Ruby, sapphire, tanzanite, aquamarine, blue topaz, citrine, amethyst, tourmaline, zircon |

| Filling with adhesive | Emerald, jade, turquoise, jadeite, malachite, lapis lazuli |

| Irradiation | Blue topaz, citrine, amethyst, tourmaline |

| Deep diffusion | Ruby, sapphie, tourmaline |

| Oiling | Emerald |

| Glass filling | Ruby |

As can be seen from the table, most stones tolerate the most ancient method – heat treatment. But other methods are also very popular all over the world. In the near future, of course, even more advanced methods of refining will be developed, but for now it is important not to make a mistake when choosing a gem and not to buy a fake of dubious quality and without special properties, but a real, albeit processed, gemstone.

Home processing tool

Processing natural jewelry or semi-precious stone at home may include cutting, polishing, engraving and grinding of gems. All actions should be carried out only with a continuous supply of water, which removes stone dust and cools the surface of the stone and tools.

Depending on the type of impact, the following tools will be required:

- continuous water supply system - you can use a sponge or a dropper;

- a cutting machine or grinder with diamond saws - for sawing hard samples;

- a hacksaw is suitable for soft stones, such as jet or amber;

- vice or clamp - for fastening the sample;

- grinding machine;

- the drill will help in making holes in stone, grinding and polishing, if you choose suitable attachments;

- the engraving set can be used both for drawing and polishing;

- sandpaper with different grain sizes;

- grinding and polishing discs of various textures;

- grinding powders and diamond pastes, for example, goi paste;

- quadrant - a device for measuring and setting angles of inclination, without which it is impossible to apply geometrically correct edges;

- kitch - a rod on which a crystal is attached during polishing or cutting.

Basic forms of cutting jewelry stones

Using cutting, you can hide inclusions in the structure, remove cracks, and correct uneven shades. Among the varieties of the process, the following forms are distinguished:

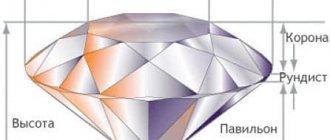

- Traditional round or rose cut. The number of facets is 57 (diamond subtype), 33 or 17. This is a universal form that can be performed on any mineral, but is more often used in relation to diamonds. This is the oldest and most proven processing method, dating back to the early 1900s. The technique demonstrates the shine and play of the mineral in the stone, and also contributes to its “longevity”. It is this form that prevents the appearance of chips or other external damage to the stone. It does not save raw materials, since up to 50% of the material is lost during processing, but the diamond can be recut. If the stone is small, weighing up to 1 carat, then the cut is made on 33 facets, and if the weight is less than 0.3 carat, then 17 facets are used.

- The oval cut also has 57 facets. Most often used in women's jewelry: earrings, rings, bracelets or pendants. The technique appeared in the sixties of the twentieth century. The elongated shape of the stone makes it possible to see the play of shades. If it is used in a ring, such a product visually lengthens the fingers.

- The Marquis technique makes 55 facets to the mineral. This cut of gemstones is used for rings, earrings or pendants. The shape of the stone is oval with pointed ends. The stone turns out to be fragile and visually resembles a smile. It is able to lengthen fingers if the gem is set in a ring. Stones of this type were worn by aristocrats; the technique was first invented in France in honor of the Marquise de Pompadour.

- The “Briolet” technique, also known as “Drop” or “Pear”. The number of facets in it is 55-56, minerals are set in necklaces, pendants or earrings. The variety combines the Marquis and oval methods. One end is tapered and protected by a rim as the sharp side is fragile. The drops come in a variety of sizes and look beautiful in hanging decorations.

- Princess cut with a number of facets of 49, 65 or 68. A relatively cheap type of processing, since the mineral loses little weight in the process. The stone is rectangular or square in shape. The technique is used for processing stones and setting them into wedding rings. But sharp corners require protection with precious metal due to the fragility of the material.

- Octahedron, or “Emerald”, which can have a different number of facets. Used for all types of men's or women's jewelry. The edges are large and not too fragile. But at the same time, the stone must have an impressive size and a good indicator of purity. It will not be possible to hide defects with such processing. You can demonstrate the saturation of the hue, the play of light will be less, but more noticeable in the brightness of the flashes. The cost of minerals after this treatment is expensive due to the characteristics of the stone.

- Usher technology. Minerals with 25, 49 or 72 facets are common, but any number is possible. This is a subtype of the “Emerald” cut, however, with a large number of floors, that is, tiers of facets. The technique was invented in Belgium in 1902 and named after the jeweler brothers Ascher. The number of facets depends on the size of the stone, but the characteristics of the gem should be almost ideal. The cut is suitable for art deco style jewelry.

- The “Radiant” method with the number of facets is 65 or 70. The stone looks like an octagon or square with cut corners. This is a combination of “Princess” and “Emerald”. The technique also requires purity, transparency and play of light. The octagon will look beautiful if the size of the mineral is large. Because of their size, stones are often chosen by men to emphasize their status, but the technique slightly shortens the fingers if used in a ring. It is good to cut polychrome minerals, as well as ametrines, in this way.

- Heart cut shape with 57-58 facets. Used for earrings, pendants or pendants. This type of stone can be given to your beloved. The main thing is to maintain proportions when cutting so that the heart does not become too fragile and vulnerable.

- “Trilliant” or “Trillion” technique. The number of edges may vary. The origin of the cut is Dutch. It arose relatively recently, in the eighties of the twentieth century. This is a fancy cut that is rarely used in practice.

- “Cushion”, the method is also called antique, or antique. The mineral is cut in this way when it is necessary to preserve raw materials and process the material as economically as possible. The weight of the mineral is practically not lost, but the appearance sometimes suffers. The corners of the mineral are rounded and the edges are wide. It even applies to diamonds.

- “Cabochon” has several subtypes, but the common feature of the stones is a round, convex shape. This is the oldest cut, which is now coming back into fashion. There are no facets in such a mineral. The name comes from the French language, because it was in France that the form became so popular that even diamonds were cut with it. Great for minerals with asterism or cat's eye effects. Ornamental or semi-precious stones are most often cut in this way. It is worth paying attention to the grinding and polishing of the mineral.

- Pentagon or hexagon are fancy cuts, shaped like geometric shapes. Sets and decorations of this type are purchased for more than one season. The processing method is only gaining popularity. Large inserts in the product are processed in this way.

To assess the quality of processing, special scales are used. The cut grade and information are indicated on the piece's certificate. If we talk about the scale of the Gemological Institute of America, then there are the following gradations:

- excellent (excellent cut);

- very Good;

- good;

- fair (average);

- poor (unsatisfactory), but the stones can be recut.

In Russia and the CIS countries, the letter value from “A” to “G” is used. “A” corresponds to first-class processing, and “G” corresponds to poor processing.

The types of stone cuts significantly change the appearance of the products and place color accents. But only jewelers understand all the intricacies of the process. Ordinary buyers appreciate the symmetry and external beauty of the mineral - this is what they should pay attention to when choosing jewelry.

Jewelry stones and gems are valued for their transparency, ability to refract light, or for their beautiful colors and intricate patterns in the case of opaque minerals. However, looking at samples extracted from the rock, it is difficult to see the beauty hidden inside. To show and emphasize the advantages of gems, the mined raw materials are subjected to additional grinding, polishing or cutting. It is stone processing that allows you to reveal the best properties of natural raw materials and increase their value.

Do-it-yourself sawing and stabbing

Processing precious and semi-precious stones is a compromise between two aspirations. On the one hand, it is necessary to maintain the maximum size and weight of the finished product, on the other hand, it is necessary to give it an ideal shape or cut, taking into account the structure and quality of the material. Based on these conditions, specialists involved in stone processing determine the required size and shape of the workpieces.

To split a piece of rock , you can use special devices, for example, a clamp with two teeth made of hardened metal. To split large pieces, you can drill holes or make a notch along the edge of the chip and successively punch the cut line using wedges and a hammer.

To cut rock yourself , you can buy a ready-made machine or assemble your own, for example, based on an electric drilling device, equipping it with a continuous water supply system. As such, you can use a moistened sponge or foam rubber, if you hold it with your left hand while cutting. However, to comply with safety precautions, it is better to use both hands during work, so under the workbench with a homemade machine, you can place a tray with water, which will cool the cutting saw blade.

If there are cracks in the sample that needs to be cut, they need to be sealed with epoxy glue for greater strength. This technology allows you to avoid unwanted splits of the material during the sawing process. Before pouring glue into the cracks, the stone must be heated on an electric stove so that the moisture evaporates. When the mineral has cooled to 60 ℃, you can apply glue, trying to ensure that it penetrates deeper into the fracture. When the glue dries, proceed to cutting.

After the raw materials are cut into pieces, they are sent for peeling, during which the workpieces acquire approximate sizes and shapes. For this purpose, coarse-grained grinding wheels are used.

Methodology and choice of processing

Sometimes the word "facet" is used instead of the term "face". Platforms, or facets, are applied to the stone so that a ray of light falling on the specimen is refracted and creates a shining effect. There are several types of cuts, but all of them, except the round one, are called fancy. The jeweler has a cutting diagram for any type as a guide for further actions.

Types of stone cuts

The cut is selected according to the following criteria:

- Characteristics and type of mineral. The quality of fragility is especially influential, since if cut carelessly, the stone can crumble in the hands of a jeweler.

- The number of defects and their location in the mineral. These defects can be hidden with the help of proper cutting and the fall of the rays onto the stone.

- Unlocking the potential of the mineral and its best qualities, while saving raw materials.

- The complexity of the process in relation to a specific mineral. Depending on the complexity, the cost of the product may increase.

- The size of the stone and the skill of the cutter also influence the choice of technique.

How to polish to a shine

If the refining of precious stones involves changing their properties, then polishing uses the qualities inherent in the mineral itself and emphasizes its natural advantages.

The main secret to successful polishing at home is a gradual change of abrasives: from larger to smaller ones. At the end of the process, it is better to use soft polishing pastes depending on the type of mineral.

Preparation for polishing

Polishing is the final stage of processing natural stone. After this, the gems can be used as inserts in jewelry and other jewelry.

Before you start polishing the stone yourself, it must be sanded. That is, its surface must first be leveled. This can be done either manually, using sandpaper wrapped around a hard base and moistened with water, or using a special tool.

For grinding, in addition to the machine, you can use a grinder or drill, on which you will need to install special attachments. The polished surface of the stone will be even and smooth, but still without a mirror shine.

To polish a mineral to a shine, you will need laps made of felt, leather or fabric , as well as polishing pastes or moistened fine-grained powders - chromium oxide, diamantine, diamond or tripoli. Materials should be selected depending on the characteristics of the raw materials being processed.

A popular method for polishing stones is felt combined with diamond powder, but it is not suitable for minerals with an irregular structure such as fibrous or grainy. Because they are prone to underpolishing: holes or protrusions often form on their surface. To polish such minerals, it is better to use wood or leather.

How the process works

The final processing of the surface of a jewelry stone takes place in several stages:

- To prepare the polishing surface for work, you need to moisten it with water and a small amount of detergent.

- You need to let the polisher run idle so that the moisture is evenly distributed and the excess is removed.

- Apply diamond powder to the faceplate.

- Moving from the center to the edge, they begin to polish the product, pressing it with force against the surface of the faceplate.

- As the surface dries, friction will increase and more effort will be required to hold the crystal.

- To prevent overheating of the working surface, water should be periodically supplied to it. In order to correctly adjust its feed, it should be borne in mind that the harder the stone, the more pressure and the drier surface of the faceplate it requires to be polished.

- Finally, you need to polish the surface with a soft material, such as felt.

During operation, it should be taken into account that if the grinding machine has the ability to change the rotation speed, then in order to avoid underpolishing of the samples, it is necessary to select indicators within the range of 500–2000 rpm.

Processing stones at home is an interesting hobby that can generate income. Working with precious minerals requires certain skills and knowledge. However, in addition to gems, simpler stones, such as cobblestones or pebbles, are also processed: their surface can be engraved, and beautiful samples can be used in interior or garden design.

History of technology development

This respected business has a rich and fascinating history. It is human nature to strive for the ideal, so our ancestors, not coming to terms with the natural beauty of stones, tried to make their appearance more attractive.

For these purposes, minerals were kept in specially prepared solutions or in natural substances, for example, honey. There have been attempts to paint gems with ocher, bake them inside bread, and treat them with copper sulfate and hot wax. Many things were used to make the crystal more beautiful than it was. Some manipulations led to the desired result, then they were improved and continued to be used. Most of the methods, which is logical for the experimental procedure, turned out to be ineffective, but people gained valuable experience and from now on knew what to use and what to use was absolutely pointless. Over time, each method became more advanced. Alchemists, who gradually began to transform into chemists, began to invent more technologically advanced solutions, and stones were processed with increasing quality from century to century. Subsequently, people realized that ennobled gems are no worse than untouched ones. Their prices are almost equal. Physical experiments and research have revealed a number of ways in which it was even possible to change the crystal lattice of stones. It turned out that streams of tiny particles of a certain mass can produce a truly magnificent effect. People began to understand how crystals are formed, thanks to which it became possible to change the color of a particular mineral under artificial conditions.

Nowadays, the process of refining precious minerals involves the use of the most advanced technologies. At the same time, the old, but still effective methods have not been forgotten. Now they are used both individually and in combination with each other. For example, temperature exposure is often combined with exposure to certain chemicals. Now it’s even difficult to say which method is more effective: the new one or the old one. For example, it is impossible to determine what gives the stone more shine and color saturation: heating in the sun or baking in ash, filling cracks with polymer or rubbing oil into them. At the same time, the newest methods have one undeniable advantage: less labor intensity.

How to care for jewelry - wooden, stone, silver

Jewelry has become an important attribute in the image of a modern woman. Necklaces and necklaces, beads, pendants, bracelets, earrings - all this wealth fills the endless boxes, boxes and cosmetic bags of a real fashionista. To ensure that your favorite accessories do not lose their original appearance, they need proper care.

In this article we will tell you about the basic rules for caring and storing wooden jewelry, as well as products made from natural stone and silver.

How to care for wooden jewelry

Let’s immediately dispel the myth that wooden jewelry is short-lived and quickly loses its visual appeal. With proper storage and basic care, the tree will serve you for many years.

Basic rules for careful storage of wooden jewelry

- Do not expose jewelry to mechanical stress. Try not to drop your wooden beads and bracelets on hard floors, especially concrete and tile floors. Dents or cracks will appear on the parts, decorative elements may fall out, which, you see, at best will not add attractiveness to the product, and at worst, serious damage may not be subject to further restoration.

- Store accessories separately from scratchy metal objects (tweezers, scissors, pendants with sharp edges). They can also cause damage;

- Avoid prolonged exposure to direct sunlight.

This will dry out the wood and it may change color or crack. The same applies to heating devices (central heating radiators, oil radiators). Even if your favorite beads or earrings get wet, do not dry them this way. It is better to dry the wood naturally, in a well-ventilated area. If your house is very hot and dry, put them in a box with a lid and put them in a dark corner; - Wooden jewelry does not withstand the effects of household chemicals and alcohol-containing liquids.

If you use products for styling and fixing your hair, as well as eau de toilette or perfume, take off your accessories, or better yet, put them on last, when your look is completely completed. Wood-destroying substances also include bleaches, filler for gel and ballpoint pens, felt-tip pens, markers, and medicinal alcohol solutions.

To understand the principle of care, you need to know the main ways manufacturers protect their products.

- Coating wooden parts with clear varnish

- Wax protection

With the first method, the strength of the product and its shine increase, with the second, the jewelry retains its natural texture and looks more natural.

Typically, souvenirs and jewelry made of ebony or mahogany are treated with wax. These breeds are very expensive, and it is extremely rare to find products made from them in Russia.

We used to call cherry wood mahogany, and black the dark brown color of some tree species, such as oak.

Under the influence of time and sunlight, beads can change their color - varnished beads, as a rule, become lighter (due to the destruction of the varnish layer), while those treated with wax, on the contrary, darken (due to oxidation processes).

How to properly update your appearance

To make your jewelry look attractive longer, periodically pamper your favorite earrings, necklaces and bracelets made of wood with caring treatments. The tarnished product is rubbed with a dry soft cloth or treated with natural oils. Olive or flaxseed will do.

You need to apply the oil to the surface, leave for 30-40 minutes, and then wipe with a terry towel or any other cotton cloth. Make sure that parts are not cleaned with abrasive agents.

If the decoration has carvings, accumulated dust can be easily removed with a regular paint (or blush) brush.

Caring for jewelry made from natural stones

There are a great many varieties of stone from which jewelry is made. All of them are divided into three categories:

- Jewelry (precious);

- Jewelry and ornaments;

- Ornamental.

Each category includes a specific list of minerals, which, in turn, are divided into classes. We will not go into detail into the classification of this natural material, but will consider the general rules for caring for jewelry made from natural stone, and also focus on several of the most common types.

Let's start with the fact that stones have different chemical compositions and physical properties, which means that some are very hard and are used to cut softer rocks (for example, diamond), while others have a more porous structure, therefore, numerous environmental factors the environment affects them many times more.

Therefore, the first rule will be to store jewelry separately. The ideal way is to have a personal velvet or fabric bag for each accessory. This will prevent softer minerals from being damaged by harder ones.

Most of the dirt accumulates in the places where the stone is inlaid and in the fasteners. You can remove everything unnecessary using a regular cotton swab dipped in warm water. Do not try to clean jewelry with sharp metal objects; you may scratch the mineral or damage the fastenings. It is better to use special products that are sold in jewelry stores for certain categories of minerals. The assortment is quite wide - foams, napkins, solutions.

The most difficult ones to care for are natural stones of organic origin: amber, pearls, turquoise, opal.

Let's look at them in a little more detail.

- Amber is a soft and delicate stone; caring for it requires special care.

It is extremely sensitive to chemicals and alcohol solutions, so do not wash dishes, do not clean items containing amber, and also make sure that drops of perfume or hairspray do not come into contact with it. Under the influence of all these substances, a white coating appears on the surface of amber, which is almost impossible to remove. Protect this fragile mineral from severe temperature changes and prolonged exposure to direct sunlight; - Pearls love moisture very much. With constant dry air, high temperatures and exposure to sunlight, it dries out and cracks. Also be careful with cosmetics and perfumes. Avoid getting them on the pearl beads. It is advisable to store a string of pearls in the shade, separately from other jewelry, wrapped in a soft cloth;

- Turquoise is a stone that tends to lose its color.

This happens due to the porous structure of the rock, which absorbs any evaporation of fats and oils. Avoid contact with turquoise jewelry with soap solution, creams and other cosmetics; - Opal is also a porous rock that does not like sudden changes in humidity and temperature. It may crack and lose its color and shine. Protect opal from mechanical stress and cleaning with abrasives. Treatment with glycerin will be beneficial for this stone.

When buying a piece of natural stone jewelry you like, ask the seller about the rules for caring for this particular mineral.

Caring for silver at home

Our parents cleaned silver items with tooth powder or soda. The immediate effect, of course, was noticeable, they brightened, but still, you should not rub silver with abrasive substances. This method destroys the polish, which is so necessary so that the jewelry does not lose its shine.

So that silver does not darken

- Do not store it in areas with high humidity (bathrooms, kitchens);

- Do not clean with chemicals;

- When preparing food, avoid metal contact with foods containing hydrogen sulfide (for example, eggs)

Also, the reason for the darkening of a silver item can be the illness of the person who wears it.

If the silver does turn black, there are several simple and effective ways to clean it.

How and what to properly clean stones with?

In this article:

- Cleaning dirt from stones

- Cleaning gems from negative energy

Cleaning stones from plaque and dirt, as well as negative energy, is an important step in caring for jewelry. The fact is that stones, like any creatures on earth, love to be looked after. You need to clean your favorite products 1-2 times a month - this will be enough to bring the mineral back to normal and restore not only its shine, but also its strength.

Cleaning dirt from stones

It's no secret that plaque and dirt accumulate on the surface of products. Dust, contact with the human body and other negative factors affect the condition of the jewelry. As a result of active wear, the minerals darken, and to eliminate this defect you just need to clean the jewelry. You can do this in several ways:

- Polishing.

- Cleaning with matches.

- Washing with water.

- Baths with salt.

Polishing is the easiest and most effective way to remove contaminants from the surface of a crystal. Naturally, polishing will not remove stains and cloudiness, but it will help remove dust and dirt from the surface of the mineral that has accumulated on it throughout the day. Polishing the jewelry is easy; suede or cloth is suitable for this. The stone is carefully rubbed with a cloth, as a result of which it begins to shine.

Matches help remove contaminants from the surface of minerals. Such a procedure requires attention and diligence. To do this, simply light matches, then extinguish them and rub the stones. They say that this method helps remove even old contaminants from the surface of the crystals.

Sometimes, in order to remove plaque and dirt from the surface of stones, you just need to wash them. The procedure is carried out using a soap solution and a toothbrush with soft bristles. The mineral is kept under a stream of water for several minutes and thoroughly rubbed with a brush, then polished with suede, velvet or flannel. But it is worth considering that some pebbles cannot be washed; they are afraid of water and can simply dissolve during the cleaning process.

Salt will help remove dirt from the surface of jewelry. To do this, simply immerse jewelry with stones in a salt solution. The solution should be cool or warm, but not hot, since minerals are sensitive to high temperatures. The whole procedure lasts a few minutes; you should not immerse the crystals in the solution for more than half an hour. After finishing the treatment, wipe the jewelry with a dry soft cloth.

When deciding to clean stones, it is worth keeping in mind that there are a number of rules that cannot be broken. The fact is that crystals are afraid of:

- high temperatures;

- aggressive reagents;

- soaking.

Various types of stones are afraid of high temperatures. For this reason, it is not recommended to heat jewelry, boil it, or immerse it in hot water. This will cause the mineral to darken and stains to appear on its surface, which will be difficult to get rid of.

You should not clean gems with reagents - acids and alkalis will harm the gems. They will lose their shine and color, and some substances can decompose the stone into molecules. For this reason, if the crystal needs cleaning, you should not experiment; it is better to give preference to specialized pastes. You can take your jewelry to a jeweler, he will remove dirt and plaque from its surface.

Jewelry inlaid with stones should not be soaked; leaving jewelry in water for a long time will not do them any good. Minerals may fall out or even lose their color. That is why you should not keep products in water or solution for more than 20–30 minutes.

Experts also advise storing jewelry with crystals that are not very hard separately, since other jewelry can damage the stones and scratch their surface. It is possible to correct such a defect, but to do this, the jeweler will have to grind the gem and remove shavings from its surface.

Cleaning gems from negative energy

Energy charging of stones is also considered cleaning, only it is not dirt and plaque that is removed from the minerals, but negative energy. Gems, like a sponge, accumulate bad emotions, for this reason it is worth treating the crystals after every scandal or major quarrel. To ensure that the stone does not stop working and brings good luck to the owner, it is necessary to regularly treat it. In this case, the procedure should be carried out for all gems, even those that were just purchased in the store.

So, how to rid a crystal of negative energy:

- You can charge it with sunlight.

- Clean with salt.

- Treat with fire.

- Energize with herbs.

- Cleanse the mineral with moonlight.

The rays of the sun help rid the crystal of negative energy; to do this, leave the gem under the rays of the sun for several hours. To carry out the procedure, you should choose a suitable place - place the stone on the windowsill so that the sun's rays shine directly on it. The procedure lasts from several hours to several days; it will help charge the crystal with positive energy and cleanse it of negativity. But it is worth keeping in mind that the light of the sun can spoil the stone and change its color once and for all.

Cleaning with salt is carried out in several stages; it comes in two types. To charge a mineral with positive energy, simply immerse it in sea salt. Salt crystals will absorb negative emotions and rid the jewelry not only of negative energy, but also of dirt and plaque. The stone is cleaned for 2-3 hours, all this time it should be in a glass or ceramic container with salt.

There is another way that will help restore the energy of the stone; for this, select glass or ceramic dishes and pour warm, clean water into it. Then sea salt is added to the water. When the water has cooled and the salt has completely dissolved, the jewelry is immersed in the solution; the procedure lasts about 30 minutes. Afterwards, remove the product from the solution and wipe with a dry, clean cloth.

The next type of purification of minerals from negative energy is complex, but effective - the stones are treated with fire. To do this, you should light a candle and learn a prayer. The gem is held over the fire and moved clockwise or counterclockwise, while a prayer must be read. The fire will take away the negativity and make the crystal completely clean. It should be placed on the table, and then put away in a dark place where the decoration will remain for several days.

It is not difficult to charge gems with the energy of herbs; to do this, you need to grind the medicinal herbs and place them in a glass bowl. Then you need to put jewelry in the mixture of herbs. They should be in the herbs for several hours.

They also fumigate with herbs - they are set on fire in a bowl, and then the stones are treated with a stream of smoke. You don't want to light a whole fire that will produce clouds of smoke; a few flowing ribbons of smoke are enough to charge the stone. If the smell bothers you, then add lavender to the bowl; it has a pleasant aroma.

The light of the moon is directly related to the energy of stones. It is used by magicians and sorcerers to make a powerful amulet from one or another gem. It is worth charging the crystals at a certain time; early March is ideal for this.

When the moon enters the Aries phase, the mineral is placed in a special container and a location is chosen. The light of the moon must fall directly on the stone, only in this case it will absorb the energy of this planet. If possible, it is better to leave the gems in the fresh air.