Milanti invisible necklace on a fishing line, cubic zirconia pendant

1450 ₽ More details

Milanti invisible necklace on a fishing line, cubic zirconia pendant

757 ₽ More details

Pendants with garnet

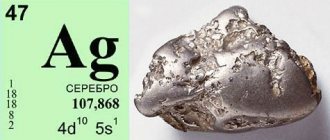

Silver was and is loved all over the world and is often preferred to the more valuable gold. Various things have been made from this beautiful light metal for centuries: cutlery, candlesticks, boxes, etc. However, it is most widespread in jewelry. Experienced craftsmen used their imagination to craft precious metal into intricate rings, earrings, bracelets, necklaces and pendants to adorn the bodies of kings, princesses and wealthy citizens. Nowadays, silver is considered a “feminine” metal, since products made from it are worn more by the fair sex. But often silver chains can be seen on men’s necks.

Not everyone can afford jewelry made of pure silver, as they are expensive. In addition, the highest grade metal is impractical. It is soft, so it scratches easily. Openwork jewelry made from it, when worn every day, quickly loses the expressiveness of its relief and is no longer as beautiful as before. Therefore, in jewelry, alloys of silver with other metals (ligatures) are used. Different types of alloys impart hardness to the precious material and increase its wear resistance. Thanks to ligatures, modern jewelers can make silver jewelry using the most complex techniques. What kind of silver alloys are there?

The influence of metals on the quality of the alloy

In the modern world, copper is added to liquid silver as a common alloy; it is believed that these 2 metals interact well with each other.

Small amounts of nickel, cadmium, zinc and other impurities are also introduced into the alloys, with or without copper, which not only improve the quality of silver products, but can also deteriorate them.

So, if the alloy contains 1% nickel, then its strength increases, but with a content of 2.6% the impurity makes the alloy brittle. If more than 9% tin is added to silver-copper alloys, it begins to melt, oxidize and increase the fragility of the alloy. For the same reason, a content of more than 6% aluminum in the alloy is undesirable. Cadmium and zinc reduce the melting point, are resistant to tarnishing in air, are ductile, and are easy to process. If the alloy contains from 15 to 21% zinc, its beneficial properties are negated. Copper in combination with cadmium forms a rather fragile compound. The content of silicon and lead should not exceed more than 1.5% in the silver-copper compound, as it becomes brittle, and phosphorus, sulfur and lead should not be present at all in the precious metal as alloys.

Because of the problems described above, jewelers prefer to add the best metal for it - copper - to pure silver. From 5 to 50% of this golden-pink metal can be injected. With a small copper content in the alloy, the products look great and are close in appearance to pure metal.

The more copper a compound contains, the more its color will differ from pure silver. If the finished jewelry has a slight reddish tint, this is the first sign that the alloy contains 50% copper. If the redness of the product is noticeable, this indicates the presence of more than 50% copper in it. In the markets of Arab countries, jewelry of this type is very often found, and sellers assure gullible tourists that they contain at least 60% silver. Although silver products are cheaper in eastern markets, it is better to buy them in specialized stores. This will serve as a guarantee of the quality of the jewelry and help you avoid buying fakes.

Properties of alloys

Silver alloys, in addition to the precious metal, contain impurities that determine the properties of silver:

- nickel: enhances the strength of the metal;

- lead: makes silver brittle when heated;

- tin: with a small content in the alloy, it lowers the melting point of silver, but if there is more than 9% tin, the alloy will become too brittle;

- aluminum: also makes silver brittle;

- zinc and cadmium: lower the melting point of silver, so they are used to make silver solders.

Precious metal alloys are widely used in industrial production. For example, the so-called technical silver (or metal with a purity of 999), mined through refining. This metal is an excellent conductor of heat and electric current, and also has reflective properties, which allows it to be used for the manufacture of high-precision mirrors.

Silver is also included in solders used for soldering jewelry pieces, seams, etc. The metal is also used in the manufacture of silver-zinc batteries and batteries.

Argentum is widely used in medicine, and all thanks to its disinfecting properties, for example, silver effectively disinfects water.

If a person wants to purchase high-quality silver products, he must make a purchase in a jewelry showroom or store that sells certified goods. It is not recommended to buy precious jewelry from private individuals, as in this case there is a high risk of purchasing a fake.

How to understand silver samples?

Samples help to find out how many percent of copper is added to the precious metal: their number, consisting of 3 digits, indicates how many grams of pure silver are contained in 1 kg of the alloy. In world jewelry practice, there are specially accepted standards for assaying silver and gold alloys, which manufacturers of precious jewelry must comply with. In Asian countries they produce jewelry masterpieces of 600 standard, although they are not of high quality and quickly lose their appearance.

According to international standards, Ag 720 is considered the lowest purity. Although this alloy has a slight yellow tint, in Russia it is used in jewelry workshops for the manufacture of locks and clasps for chains and necklaces.

Cutlery and dishes are produced from alloys of 750 and 800 samples. Products made from these samples require constant care, since they quickly oxidize in air.

Silver of 830 and 875 standards is suitable as a material for the manufacture of not only cutlery and utensils. It has also found application in the production of decorative decorations for room interiors.

The most famous alloy of silver and copper is sterling. It contains 92.5% precious metal and only 7.5% copper. It is the 925th standard that is most in demand in jewelry. Most of all precious jewelry is made from it. Dazzling sterling is similar in color to pure silver, but is more hard and resistant to tarnishing.

960 standard metal is also used for the production of jewelry. However, such jewelry must be worn very carefully and taken care of carefully. Due to the plasticity of the metal, the products are not durable.

Only 1% of the golden-pink metal contains 999-grade silver. Despite their short service life, Japanese residents willingly buy such jewelry. They believe that pure silver is closely connected with the Moon, which is the abode of deities who are merciful to people, and through wearing this precious metal they want to be closer to them.

Known silver hallmark systems

As in the case of gold hallmarks, metric and spool (used until 1927) silver hallmarks are known in Russia. In Western Europe and the USA, the so-called karat silver standard is used. You can read about the formula by which a metric hallmark is converted to a spool hallmark and vice versa, as well as what a carat hallmark means, in the article on hallmarks of gold alloys. And below in the table you can see examples of correspondence between samples of different systems.

What can ligatures be confused with?

Often they try to counterfeit silver alloys by replacing them with similar-looking materials. The most common of them are copper alloys cupronickel and nickel silver. Cupronickel was very famous in ancient times under the name “Warsaw silver”. Pendants and bracelets were made from it, and guns and daggers were lined with it. The material was covered with a thin layer of silver on top, so it was no different from real metal. It cost much less, and not only rich people could purchase products from it.

Nickel silver contains copper, nickel and zinc. Its color and bright shine are so similar to the precious metal that it is even called “new silver.” Nowadays, nickel silver is used in jewelry for the production of clasps and pins for jewelry, but numerous scammers can make rings and brooches from it and cupronickel to sell to gullible buyers at the price of the precious metal. Often there are no samples on such products, which should already give rise to thoughts about the dubious quality of the jewelry. Therefore, it is better not to chase rather cheap “silver”, but to buy it in jewelry stores.

Application

Jewelry, watches, tableware, interior decorations, writing instruments, and decorative elements of weapons are made from silver. Silver can be combined with gold, enamel, niello, precious and semi-precious stones, pearls, corals, and ivory. The metal is widely in demand in the chemical industry, in the production of mirrors, and also as a protective and decorative coating. High thermal and electrical conductivity make silver useful in the production of electronics and electrical equipment.

What is good about Shibuichi alloy?

In addition to the generally accepted tested alloys, there are silver compounds containing a high percentage of copper (from 30 to 75). They do not have huge value in the jewelry market, but are used in the manufacture of interesting jewelry. One such alloy is Shibuichi. It is also called “Japanese bronze” in another way, since it was invented by the Japanese, who widely used the ligature in the production of handles for daggers and knives. Now Shibuichi is used to make beautiful brooches, bracelets, rings and earrings. The word shibuichi means "three quarters" because it contains ¾ copper and only ¼ silver. The natural colors of this alloy are pale pink and yellowish white. The beauty of “Japanese bronze” is that when patinated, the material acquires a variety of shades from light gray to chocolate brown. Thanks to them, the products look unusual and fantastically beautiful. Whatever silver alloy men and women choose, they can be sure that the products will delight them with their appearance and shine for a long time.

Coatings of silver products

Currently, the most technologically advanced types and methods of coating silver products are:

- “White” boiling is boiling in sulfuric or hydrochloric acid to reduce the content of copper reacting with hydrogen sulfide in the thin surface layer of the product. The surface acquires a matte tint.

- Electroplating — applying a thin layer of precious metal using the electroplating method. Currently, electroplating is the most popular way to protect and decorate silver jewelry. Depending on the metal that performs the function of the protective layer, the following types of coatings are used:

- Silvering is a coating with a thin layer of pure silver, which reacts weaker than alloys with hydrogen sulfide in the air.

- Rhodium plating is coating with a layer of white and, less commonly, black or yellow rhodium. Rhodium is a precious platinum group metal. It is wear-resistant, does not darken, and has a beautiful mirror-like light-steel shine, which is why in the last 10–15 years it has become one of the most popular coatings on the jewelry market. If repaired by soldering, the rhodium plating turns black and cracks. In this case, the old coating must be removed and a new one applied.

- Gilding is gold plating. It is actively used for complete or partial decoration of silver products.

- Passivation (passivation) — transfer of the top layer of the alloy into a passive state, which sharply slows down corrosion processes. Performs a purely protective function.

- Oxidation is a type of passivation, the creation on the surface of a metal of a dense film of oxides that protects it from corrosion. It is both a decorative and protective coating method.

- Electrophoresis deposition - coating with organic polyurethane foam or acrylic by immersion in an aqueous solution of epoxy or acrylic resin under the influence of tension. Performs only a protective function.

What is

In the list of chemical elements, the position “cupronickel” is absent.

Cupronickel is not a metal. This is an alloy of several components.

The basic components of cupronickel are copper and nickel. They are supplemented by iron and manganese, which are added to diversify the color range and consumer characteristics of the product.

Where is it used?

The properties of cupronickel ensured its use by industrialists, decorators, and bankers.

Industry, medicine

The structure of the alloy allows all types of mechanical processing - cutting, forging, stamping, soldering. And at any temperature.

This determines the areas of application of cupronickel:

- High precision resistors, heat generators.

- Production of components for trawlers, cruise ships, ocean liners. And private yachts of the premium segment.

- In combination with lithium, nickel-iron alloys are purchased for the production of batteries. They are three times more effective than their analogues. Lithium, as the lightest metal, reduces the massiveness of the filling of nickel-zinc or ferrous batteries.

Cupronickel is a material for medical instruments: scalpels, forceps, etc.

Plus the possibility of decorative processing of products (chasing, cladding, polishing).

Decor

Decorators work with alloy in two directions:

- Jewelry. Rings, earrings, necklaces, and cufflinks made of cupronickel are indistinguishable from silver in appearance. However, large companies are not interested in the alloy due to its low cost. It is more often done by hand-made masters. The processing makes them look like museum pieces.

- Dishes. Sets of cupronickel tableware - spoons / forks / knives / sockets / tureens - are a pride and heirloom in many homes. Their advantages: they are several times cheaper than silver ones, but more durable and look presentable.

Especially good are gold-plated, silver-plated, blackened or other coated surfaces.

Applying such a layer is not only a tribute to aesthetics or status. Pure cupronickel imparts tangible metallic notes to food. Copper is toxic, especially when hot.

Banking sector

Wear resistance, coupled with low cost, prompted the National Banks of many countries to issue cupronickel coins.

Almost all silver-colored coins in circulation are made of cupronickel.

In the USSR and Russia, coinage is controlled by GOZNAK:

- In the 1930-1950s, nickels, 10-, 15-, 20-kopeck coins were issued.

Today, the subject of numismatists' hunt is a Soviet patch of the 1937 model.

- Since the 70s, the line has been supplemented with anniversary and regular “rubles”.

The last Soviet coin was the bimetallic 10-rublevik.

In Russia, until the mid-1990s, coins were minted in denominations of 10, 20, 50, 100 rubles. After the redenomination of 1997 - 1 and 2 rubles.

How to spot a fake

In Russian jewelry stores, counterfeit silver jewelry is practically never found. However, you can easily stumble upon them when shopping at a fair, market or sales.

To avoid becoming a victim of deception and the owner of an item of dubious quality, you can use a few simple rules.

- If you have a small piece of white chalk, you need to run it over the surface of the product. Contact with silver will cause the chalk to turn black, while counterfeit will have no effect on it.

- To determine the quality of the alloy, you can run a pin across it. If there is no silver in its composition, the resulting strip will be black or red.

The rules described above are highly likely to determine the correct result, but in practice they are of little use, as they damage the surface of the product. This is why other methods are more common when purchasing.

- Hold the product in your fist. If within 1-2 minutes it warms up to body temperature, this is a real precious metal; if it remains cold, it is a fake.

- Press the magnet onto the decoration. Silver will not react to it in any way, unlike iron that imitates it.

How to use and care

Cupronickel, like fine silver, fades and darkens over time. Even with proper storage, zero humidity in the room is unattainable.

Cleaning

The easiest way to add shine is to buy a special cleaner for cupronickel. Its disadvantage is the need to thoroughly rinse the item after cleaning. Especially dishes.

Generations of owners have tested methods of caring for nickel silver using improvised means:

- Apply a mixture of moistened soda to flannel, suede or other soft fabric. Rub the surface until results are obtained.

- Pour ammonia over the products, then rinse with running water and wipe dry. You can work wearing a mask.

- Boil cupronickel in a decoction of garlic, onion peels or crushed eggshells.

Cleaning with tooth powder, toothpaste, crushed chalk, or products containing bleach is excluded. The first three will scratch the product. The latter will make the cupronickel darken.

Usage

After washing cupronickel dishes after a meal, rinse them with a soda solution (45-50 g per liter of water).

Dishes or other items are immediately wiped dry to prevent them from becoming dull.

Regular thorough cleaning of jewelry or devices will not hurt even if they are used constantly. Resuscitating “neglected” cupronickel will take more time, effort and nerves.

It is better to store products (dishes and jewelry) closed in their “original” packaging. Alternatively, wrapped in cling film or foil. This will minimize mechanical or “wet” effects. That is, they will not be scratched or darken.

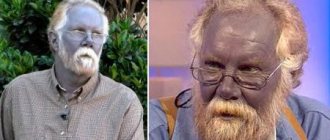

Myths about silver

- Fake silver turns black, but real (old, high-quality) silver does not turn black

A fake can also turn black for a variety of reasons, but if you carefully read our article, you realized that the formation of a thin layer of silver oxide or sulfide is normal for this metal; this is its chemical feature. And in old jewelry, not copper, but palladium and platinum were used as ligatures. This alloy did not really darken, but it was much more expensive. It's chemistry, nothing personal.

- Silver disinfects

This is true, silver has bacteriostatic properties, slowing down the development of bacteria, and a bactericidal effect, killing bacteria with the help of silver ions. But this manifests itself only in concentration, which can be harmful for you and me, because silver is a heavy metal, it is deposited in the body and can cause poisoning. It is safe to wear, but we do not recommend eating it.

You can also remove spoons, rings and pendants from the water: in this case, so few silver ions are released that they are not able to disinfect anything. This also means you don't have to worry about silverware and cutlery. If you use a special ionizer, there will be an effect, but with it it is easy to exceed the permissible concentration and again get poisoned.

If you are reading in English, here is a WHO report on the use of silver for disinfection, which generally repeats the above conclusions and speaks of the lack of information for far-reaching conclusions in most studies on this topic.

- Silver drives away evil spirits

We invite you to check this myth yourself. Find a vampire and stab him with a silver sword, but take precautions: if the sword is rhodium-plated, the effect may be disappointing.

Stamps

Cupronickel products made in Russia are marked with letters of the Russian alphabet and numbers:

- MN (copper and nickel).

- MNZHMts (plus iron and manganese).

- The numbers show the percentage of nickel, iron, manganese.

The amount of copper in the alloy marking is not indicated.

For example, the combination MNZHMts 45-4-1 is used to brand material made from 45% nickel, 4% iron and 1% manganese. The remainder (50%) goes to copper.

In industry, the most popular alloy grade is MH19. This is 18-20% nickel plus one and a half percent alloys (usually cobalt).