| Stone type | Precious |

| Prevalence (Deposits) | Australia, Brazil, Kazakhstan, Canada, Russia, USA, South Africa |

| Varieties | Ballas, Bort, Diamond, Carbonado, Yakutite |

| Transparency | Transparent |

| Shine | Glass |

| Mohs hardness scale | 10 |

| Chemical composition | WITH |

| Color | White, blue, yellow, green, red, pink, blue, black |

| Owner's color type | Summer |

| Owner's temperament | Choleric |

| Names | Venus, Daria, Ivan, Ilya, Inna, Karina, Christina, Leo, Maria, Olympics, Sergey, Eduard |

| Zodiac sign | Aries, Leo, Sagittarius |

| Date of Birth | from March 21 to April 19 from July 23 to August 21 from November 22 to December 21 |

| Chinese horoscope | Rat, rooster, tiger |

| Element | Fire |

| Planet | Not found |

| Day of the week | Monday, Friday, Saturday, Sunday |

| Month | April, October |

| Season | Spring, autumn |

| Numerology vibration | 4, 6, 9 |

| Chakra | Sahasrara |

| What stones is it compatible with? | Agate, alabaster, amethyst, white pearl, beryl, turquoise, emerald, coral, lapis lazuli, sapphire, carnelian |

| What stones is it not compatible with? | Malachite, marcasite, obsidian, onyx, sardonyx |

| Therapeutic effect (problems) | Blood pressure, insomnia, immunity, nervous disorders, stress |

| Therapeutic effect (on organs) | Skin, respiratory organs, gastrointestinal tract organs, cardiovascular system |

| Magic properties | Strengthening relationships, finances, black magic, energy depletion |

Diamond and its derivative diamond are most often associated with fabulously expensive jewelry.

However, the use of diamond is not limited to this area. This mineral is widely used in construction and medicine, in instrument making and in industries related to chemical production. Diamonds are one of the elements of space and nuclear programs and are used in the field of nanotechnology and the mining industry.

Properties and indicators

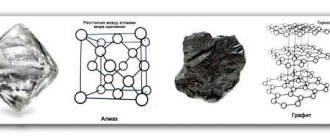

It has been known since school chemistry course that diamond is a modified form of carbon. In fact, almost everyone owns a “future” diamond in the form of a simple pencil with a graphite rod. Exposure to high temperatures contributes to a change in the structure of the graphite crystal lattice and a significant increase in the degree of its hardness. It is thanks to this indicator that this mineral is so in demand in many industries.

Be sure to check out: Is it possible to wear and accept pearls as gifts at a wedding?

All the basic physical properties of diamond can be presented in the form of a table:

| Property | Unit of measurement/characteristic |

| Specific gravity (density) | 3.4-3.5 g/cm³ |

| Thermal conductivity | up to 2.3 thousand watts |

| Friction coefficient | 0,1-0,5 |

| Moss hardness | 10 |

| Crystal Energy | 105 J/mol |

| Melting temperature | 3700-4300 C° |

| Refractive index | 2.427 (high) |

| Type of crystal lattice | tetrahedron (cubic) |

| Atomic connections | spatial |

| Light conductivity | high |

It was the combustion process of diamond that led scientists to believe that the mineral was related to carbon, which was later proven in research studies when analyzing the structure and chemical composition of the stone.

There are several varieties of diamond in nature, each of which is used in a variety of fields:

- diamond – the most valuable cut diamond;

- ballas - a fine-grained round crystal with a very strong shell;

- carbonado - a black mineral in the shape of a cube;

- Yakutite is a dark stone from the diamond family, with a large number of impurities and the highest hardness;

- board is an irregularly shaped mineral with graphite inclusions in its structure.

In industrial applications, board, ballas and carbonado are the most commonly used.

Classification

There are a huge number of classifications of diamonds according to certain characteristics. The first attempts were made in ancient India, where the color shade of natural stone was taken as a basis. Each of them: transparent, red or gray was likened to a certain human caste of the then society.

Modern methods take as a basis the appearance, presence of impurities, shape, color and a number of other characteristics. Diamonds are such a complex commodity in terms of a set of indicators that even experienced specialists are allowed to make an error (sometimes reaching the level of 15%) in assessing the 6,000 varieties of this precious raw material. However, some simple and convenient landmarks still exist in this endless variety.

First of all, diamonds are divided into technical and jewelry diamonds. The current assortment of the world market is presented:

- 50% low grade small diamonds,

- 35% semi jewelry stones,

- 15% jewelry diamonds.

On the territory of the Russian Federation, the current official document regulating the classification of rough natural diamonds is GOST R 51519.1-99. Where the main features are:

- defectiveness,

- dimension,

- form,

- color.

Construction works

One of the main advantages of diamond is its hardness. This is the strongest mineral in the world and in most cases it is this indicator that determines the wide scope of its use in construction.

Interesting! Modern construction work is carried out with the participation of volumetric structures made of concrete. Dismantling, drilling, sawing and cutting such durable materials requires not only powerful equipment, but its coated parts, whose crystal lattice is stronger and stronger.

Drills, saws and knives with a special diamond powder coating cope with granite, marble and concrete, easily grind stones and crushed stone, punch and drill holes of any diameter.

Be sure to watch: Basic ways to distinguish natural pearls from artificial ones

THE AMAZING MAGIC OF DIAMOND A diamond is a natural substance, a precious stone, and a technical raw material.

He was famous in… Posted by Lemon Saturday, November 1, 2014

Laying cables and trenches cannot be carried out without the use of special equipment - a roadheader. Its main element is a disk with a blade coated with technical diamond chips.

Cut

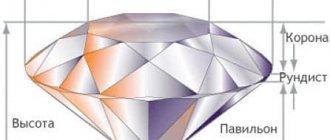

Diamonds coming in for processing, the need for which is determined by the desire to give the stone maximum elegance and beauty, by creating an optimal shape and identifying the play of light; undergo a thorough examination, sometimes taking several weeks. After which, the future jewelry item is subjected to splitting or sawing, preliminary roughening, cutting and final polishing.

Modern computer volumetric modeling programs are used to minimize losses and predict future diamonds.

Sawing

Having replaced the splitting performed by hitting a knife, sawing allows for much better use of the workpiece. Defects identified during the inspection (internal stress, stains, cracks) can be removed or localized into a smaller product.

Typically, natural diamond is sawed using a circular saw equipped with the thinnest discs up to 0.05 mm thick, coated with a diamond powder. A rapidly rotating disk cuts the crystal in the directions of least hardness, spending several hours on this operation. A stone weighing 0.2 grams - 1 carat takes up to 8 hours of sawmill time. There is another, modern method of cutting using a laser beam, which allows you to obtain more favorable shapes and reduce weight loss of the precious mineral.

Form

In order to obtain a rough shape, sawn diamonds are subjected to friction. This is followed by cutting and polishing, as a result of which the stone takes on its final shape. Recently, this process has become mechanized thanks to the introduction of semi-automatic cutting machines into production.

Marquis

The shape of the cut, with its contours, resembles the human eye - an elongated oval, ending on both sides with two sharp corners. Which, according to the French monarch, was supposed to symbolize the insidious smile of the Marquise de Pompadour.

Pear

She's a "drop". An elegant teardrop-shaped cut, so valued by the fair sex on diamonds adorning their earrings and rings. The surface of the stone shines with 56 edges.

Oval

A very simple and common form that gives its wearers elegance by visually lengthening the parts of the body wearing the finished product.

Princess

A classic, iconic, very popular cut that gives a square shape to the processed stone, although it has a number of significant disadvantages. The diamond that adorns engagement rings is fragile in the setting, often gets lost and can be easily damaged on its edges.

Emerald

An octagonal rectangle with 56 sides, most suitable for large diamonds. Emphasizing the wealth and high level of dignity of its owner.

Asher

A cut developed in Belgium, used for stones of a high level of purity. Unlike “emerald”, it has a square shape with the same number of edges.

Radiant

Rectangular shape, covered with 61 or 77 edges, made in the form of equilateral rounded triangles.

Heart

A complicated “pear” with a wide forked base. It is a rather fragile product, the strength of which is specially increased by certain geometric proportions.

Polishing

The final stage in diamond processing, designed to finally get rid of all flaws and give the precious product smoothness and a mirror-like shine. It is performed using a rotating steel circle coated with tiny particles of diamond abrasive.

Diamonds

Medicine

In medicine, industrial diamonds are a necessary element in the manufacturing process of surgical scalpels, scissors, clamps, and dental equipment. A special coating applied to the blade guarantees a more precise and neat cut. Such instruments are indispensable during complex operations on the spinal cord and brain.

Another area of application is medical lasers. The crystal is built into a complex device as a conductor. Laser operations are increasingly used in modern surgery, as they are less traumatic and require a shorter rehabilitation period for patients.

Until the mid-50s of the last century, mainly technical types of diamonds were used in industry. But after 1953 they were replaced by artificial analogues with exactly the same technical characteristics.

Use of gems in industry

Diamonds are widely used due to their incredible strength. Parts that are coated with crumbs have a long service life. The advantages also include low noise during operation, high speed of task completion and incredible cutting accuracy. The stone does not leave cracks, chips or other deformations on the surface.

For the manufacture of tools and components for them

Nowadays, diamond tools are used for drilling concrete. When processing such a surface, no dust appears and there is no vibration.

Often drills with diamond chips are used for:

- creating water supply holes;

- installation of air conditioners;

- taking samples from rocks.

This precious material has also found application in the space sector. Diamond is used to coat various devices so that they become highly durable and last as long as possible.

Telecommunications

This type of crystal helps to conduct several communication lines of different frequencies through one cable. It is not susceptible to sudden temperature changes and does not respond to power surges. The stone is also used in photocells and parts for optical instruments.

In order to get the desired result, it is enough to use a particle of stone that will be invisible even to the human eye.

Medicine

In this area, diamond is an indispensable item. Surgical scalpels are processed with a similar stone. Thanks to it, sharp blades make thin cuts, which is important in medicine.

The latest development of scientists is a medical laser. Its main component is diamond, which acts as a conductor.

Nuclear industry

In this area, diamond is used to create nuclear radiation. When a particle is charged, a flash is formed in the stone, from which a current pulse appears. No other gem evokes such a reaction.

Chemical and physical sphere

Since diamond, compared to other stones and materials, is not susceptible to the effects of various acids, it is used as a protective element. All parts that are created on the basis of diamond are error-free and work properly for many years.

Chemical industry

The high hardness of the mineral determines the high protective properties of materials made with this coating. Diamond can withstand acids, alkalis and high pressure. It has proven itself to be the best after experiments in the field of quantum physics and was even included in the list of materials used in space shipbuilding.

Diamond stone.

Properties of diamond. Description of the diamond. Diamond is perhaps the most popular, most precious stone in... Published by the Diamond House “Lizard” Wednesday, January 16, 2013

Diamond processing

Before processing a diamond, the jeweler selects the best material without significant damage or natural defects. If there are microcracks on the stones, they are removed or masked using special devices that change the structure using environmental indicators.

After this, cutting is carried out. The most popular diamond shapes are hexagonal. This type of cut is considered universal, as it is suitable for diamonds regardless of the type, color and natural characteristics of the specimens. Moreover, this form allows you to preserve the natural size of large and medium-sized gems and not reduce the size of small crystals even further.

Jewelry craftsmanship

The most famous industry where diamonds are involved is the jewelry industry. Moreover, here the mineral is used both as an object and as a means of processing it. Diamond-coated equipment is a necessary condition for high-quality cutting. It is with its help that a precious diamond is born from a modified form of carbon - one of the most expensive gems in the world.

This stone is often the centerpiece of imperial and royal treasures. Both the crown of the Russian emperors and the crown of the British Empire are decorated with it, and it is inserted into sceptres, royal staffs and orbs. Owning jewelry with diamonds emphasizes the status and position in society and demonstrates the financial condition of the owner. Jewelry with this stone often became family heirlooms and was passed down from generation to generation.

The value of diamond jewelry does not decrease over time, but only increases in price.

Extraction methods

Extraction of minerals to the surface is always associated with serious costs, and the choice of the method itself is largely determined by the depth of the ore rock. Often, having exhausted the capabilities of the surface layers, miners are forced to continue development, going deeper into the bowels of the earth.

Before starting the actual production of useful rock, it is necessary to conduct geological exploration, make a decision that is reasoned from various sides, create the necessary infrastructure, transport people and equipment, organize enrichment and processing.

Shakhtny

Where there is confidence in diamond deposits at a depth of more than 500 meters, the only mining method is the construction of underground structures. Although there are exceptions.

The method is quite expensive and unsafe, but very often it is the only one and also opens up access to new deposits. A serious problem in such cases is water and escaping gases; it is also necessary to constantly monitor the air supply and stable power supply. Inside the mine, mining equipment is constantly operating: combines, loading and unloading machines, conveyor belts, skips. After which the ore mined to the surface is sent for processing.

Career

An industrial method of diamond mining, used everywhere, but associated with drilling operations and the organization of explosions. The raw materials obtained in this way are loaded onto multi-ton dump trucks and sent to a processing plant that extracts diamonds from the rock.

Once one layer is exhausted, the quarry is expanded and deepened as long as conditions allow. If necessary, the mining process often moves into the closed stage of underground mine construction.

Diamond mining

Main conclusions

Diamond is not only a beautiful and fabulously expensive gemstone that can be seen in exclusive jewelry. The scope of its application is much wider.

- Diamond is a modified carbon, a relative of the familiar graphite.

- This mineral demonstrates the highest strength, which allows it to be used in many fields.

- Construction, medicine, nuclear and nanotechnology, instrument making are just a small part of the industries where this stone is in demand.

- Since the second half of the last century, technical varieties of diamond have been replaced by an artificial analogue.

A precious mineral, closely connected with the history of mankind, has long ceased to be just an element of decoration. It has become an integral factor in technological progress and the process of scientific modernization.

Use in production

Not everyone uses diamonds in production. High-quality material has a high price, so it is irrational to use it on a large scale. Artificial diamonds are most often used in production.

Despite its advantages, diamond is a rather fragile stone.

They are obtained in several ways:

- From steam. For this, the chemical deposition method is used.

- Using high pressure and maximum temperatures.

- A substance containing a large amount of carbon is undermined.

Those stones that have not been cut are classified as industrial diamonds. They are also used to make tools.

Diamonds are made from:

- drill;

- grinding tools;

- scissors;

- cutters;

- glass cutters.

Thanks to such details, high-quality metal turning occurs. Drills for drilling oil wells are also coated with crumbs.

Artificial analogues of diamonds

Thanks to research, it was possible to discover a method for synthesizing agglomerate, thanks to which it is possible to create stones identical in structure to natural diamonds. Synthetic specimens - cubic zirconia - are close in their characteristics to real crystals. The creation of synthetic diamonds is a necessary measure, since the existing reserves in the deposits are not enough to provide all areas of industry with a large number of stones. Despite the efforts of scientists, there are minor differences in the appearance and structure of diamonds and cubic zirconia.

Natural and synthetic diamonds are very similar, but not identical.

Color range of laboratory stones

Gas colorless diamond is a popular option. It is these stones that are more valuable in the jewelry market. But the difficulty is that it is more difficult to grow a transparent diamond than others. It requires effort and strict adherence to temperature parameters during production.

Transparent diamonds are obtained only if boron or nitrogen is not present in the original composition. Even the smallest ingress of chemical elements into the composition leads to tarnishing. This is not uncommon, which is why diamonds that are completely clear are the most expensive. They sell at a price identical to natural diamonds. Specimens from 1 carat are valued.

Synthetic colorless diamonds

Blue diamonds are produced by adding the element bromine to the crystalline carbon lattice. If a minimum of it hits, the finished diamond acquires a slight bluish tint. With a large ratio, the resulting stones have a bright blue tint.

Gold earrings with synthetic corundum and diamonds

Yellow, unnatural diamonds are produced by adding nitrogen. Receiving on the company’s equipment takes a minimum of time, so such options do not have a high price. You can make lemon, orange, yellow, sand variations.

Engagement ring with synthetic yellow and clear diamonds

Recently, black diamonds have begun to be created in production. They look interesting and are suitable for stylish jewelry. In the form of inserts they are used for rings, earrings and necklaces. Nickel is used during the production of black diamonds.

Black diamonds created by synthesis

Origin of the diamond

The main diamond deposits are located in:

- Africa;

- Russia;

- Australia;

- Canada.

Since mining began long before research into the crystal, natural treasures have been significantly depleted. This is reflected in both the price and quality of the extracted material. However, Brazilian and South African deposits, discovered only a century and a half ago, continue to provide humanity with rare, but very elegant gems. The origin of each stone affects its physical and chemical properties , as well as its price and appearance.

We're digging

So, how to get diamonds in Minecraft if you are already fully prepared? You have at least two options.

- We go down to a depth of 12 blocks and set up a room for ourselves with all the equipment indicated above. We illuminate it completely. We must install a door at the entrance. Now you have three bare walls. Start digging straight in one direction. The hole should be 2x2. Every two blocks you create a half-room, from which a branch will later be built. It will also be 2 blocks in height, but in width and length it will be 4. Then again we dig a 2x2 corridor. And so - as long as endurance is enough. It’s better not to go too far: you might fall into a cave or dig up a lake. In the same way, from the initial room we swarm to the remaining directions. After you have dug in all directions, you can move on to the branches and dig them according to the same principle as the main tunnels.

- We go down to the maximum depth and look for lava. Dig along and next to it, and also try to use the tips from the previous paragraph.