Coasters, once common everyday objects, now occupy museum shelves. However, even in our time, connoisseurs of Russians often

It is not easy for tea traditions to carefully store these items, but they also use them for tea ceremonies. The glass holder, as a cult attribute of primordial traditions, turns simple tea drinking into a kind of sacrament, conveying the meaning inherent in it.

Coasters from the Soviet period in particular carry a meaning and reflect the spirit of their era. Labor achievements, the Great Victory, the conquest of space and other significant events are forever imprinted on these objects.

Since the 30s. In the 20th century, accessories for tea making were produced in many factories, artels and jewelry workshops. Moreover, each product was marked with a mark. The mark was applied in the form of an imprint and carried information about the manufacturer and material of manufacture. In some cases, the date of issue could be determined by the stamp. Most items, with the exception of silver ones, were additionally branded with the letter “C” and a number, which indicated the value of the item.

How to find out if a spoon is a silver spoon or not: getting results at home

Not every family can boast of having silver cutlery, and there are very few owners of complete sets. It would seem that silver is not a very expensive metal - a simple ring can be purchased for only a thousand rubles.

Why is silverware so expensive? And you count how much precious metal it takes to make one silver spoon. Plus work, a brand and other extras - a substantial amount accumulates.

Therefore, often the desire to determine the authenticity of silver spoons is not a whim, but a matter of prestige, the feasibility of financial investments and the characteristics of care. Especially if we are talking about family or any other rare silver.

How to tell if a spoon is silver

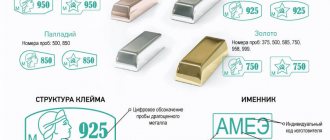

Silver is a precious metal, which means that all products made from it are subject to hallmarking. In addition to the required image, the mark contains numbers reflecting the percentage of metal content.

Nowadays three-digit hallmark designations are accepted, but in tsarist Russia they were two-digit. And the brand looked completely different.

Pure silver is used exclusively for technical purposes. In the production of jewelry and decorative items, as well as cutlery, silver is used with additives that give it strength.

The most popular additives for silver are copper and nickel. This is why silverware often has a yellowish tint - these are traces of copper. The higher the sample, the less noticeable this yellowness is.

So factory-made silverware is always hallmarked, but there is still a risk of running into a fake - craftsmen have learned to falsify even standard hallmarks. However, silver is supplied with fake hallmarks much less often than gold (simply unprofitable), and the quality of the imprint itself leaves much to be desired.

If there is no mark on the product or you doubt its origin, you can check the silverware for authenticity using homemade methods:

- Chalk. Run a regular chalk across the surface of the silver - a dark mark will remain on the white mineral. True, some other metals (for example, tin) demonstrate a similar reaction, so this test is not very informative.

- Sulfur ointment. Sulfur is the worst enemy of silver: upon contact with it, the noble metal is covered with a dark layer of sulfide. Apply sulfur ointment to a small, inconspicuous area, wait 10-15 minutes and watch the metal react.

- Lapis pencil. The ancient styptic can be used to test gold and silver. It contains silver nitrate, and it does not leave the slightest trace on precious metals.

- Iodine. But silver reacts to iodine - dark spots remain. If the spots are a different color or there is no reaction at all, then this means that this is a fake. The only disadvantage of this method is that it is difficult to remove a dark stain from silver later.

- Ice. Silver has high thermal conductivity: a piece of ice placed in a spoon will begin to melt rapidly. To compare the result, it is advisable to simultaneously perform a similar experiment with a guaranteed non-silver spoon.

If you want to get a perfectly accurate result, buy a special test at a jewelry store. It is inexpensive, but allows you to instantly resolve doubts about the “pedigree” of the product.

The methods described above are relatively good, but there are a lot of nuances that reduce the accuracy of testing.

To begin with, in most cases we do not test the entire product, but its surface, so a silver-plated spoon will test positive for silver. The only way to get to the truth is to scratch deep into the surface and test there. By the way, silver-plated products are not branded!

The second nuance is rhodium-plated (that is, rhodium-plated) silver. Rhodium-plated silver does not darken over time, has an elegant shine and demonstrates much greater strength. There will be a factory mark on it, but the rhodium-plated surface, naturally, will not give a positive reaction to silver.

How much does a silver table spoon weigh?

Silver is a dense and, accordingly, heavy metal. A silver tablespoon will be much heavier than a steel one, and even more so an aluminum one. True, cupronickel cannot be called light either.

Brand on the cup holder

The most common were cup holders made of cupronickel, which had 2 types of marks: “MELCH” and “MNTs”. The first mark belongs to an earlier period and is abbreviated as cupronickel. Later, cupronickel became more widely used, and some alloys began to be supplemented with lead. Material containing lead was not suitable for food purposes. For the production of cup holders, spoons and other tableware, cupronickel, which contains lead in its pure form, was not used and was used only with silver plating. That is why the new “MNC” brand was introduced. The MNTs cup holder was distinguished by a stable matte shine, similar to silver. Three capital letters indicated the composition of the alloy - copper, nickel, zinc.

How to distinguish a silver spoon from a cupronickel spoon

Cupronickel is an alloy of copper and nickel, that is, the same metals that are usually added to silver-based jewelry alloys. It has been known almost since the beginning of our era, but it began to be actively used for the production of cutlery relatively recently, about 150 years ago.

Mark on a cupronickel spoon

In Soviet times, cupronickel cutlery was very popular and was the pride of middle-income families. They were traditionally marked with the mark “MELCH”. But there are other analogues of silver: Monel (“MN”, cupronickel with a high nickel content), nickel silver (“MNTs”, with the addition of zinc), silver-plated brass, and so on.

It is quite difficult to distinguish silver from nickel silver on cutlery at home, especially if there is no factory mark. You can scratch the product: a dark mark will remain on cupronickel, and a light mark will remain on silver, the metal’s own shade. But it is better to use the jewelry tests already mentioned above.

And finally: never buy silverware second-hand without a preliminary professional assessment, and then you will not have to suffer from doubts!

Source

Stamps on cutlery made of cupronickel from the USSR period

Kiev plant of cutlery and dishes named after. Dzerzhinsky.

During the entire period of mass production of silverware from the early 50s to the end of the 70s of the 20th century, about half of all Soviet silverware and nickel silver were produced at this plant. The plant produced a diverse range of products, but only a few design series. Three of them inherited the motifs of the famous design of the tsarist times “Oak” and “Faberge Drawing” of the early and late varieties.

The other two, "Kashtan" and "Kyiv", were developed by factory designers. The latest design, "Kyiv", turned out to be very elegant, functional and comfortable. This design was borrowed by the Moscow cupronickel products factory (later “Moscow Made in USSR”).

The popularity of the products of the Tallinn Jewelry Factory was facilitated not only by the excellent quality of the products, but also by the fact that in addition to traditional knives, spoons and forks, the factory produced a variety of serving products. The plant also produced cutlery from cupronickel.

Platinopribor (Moscow Platinum Plant).

The Moscow plant, created on the basis of the factory of I.P. Khlebnikov, nationalized in 1918 by the Soviet government, which since 1872 had the title “Supplier of His Imperial Majesty” (“Supplier of the Russian Imperial Court”) and at the same time the title of supplier to the courts of the kings of Denmark, the Netherlands and Serbian, as well as the Prince of Montenegro. Initially, I.P. Khlebnikov’s enterprise was transformed into the “Moscow Platinum Plant”, the main products of which were all kinds of products for the electrochemical industry and scientific laboratories. The plant produced small quantities of silver and cupronickel jewelry, mainly tableware items - spoons, forks, glass holders. They were marked with the mark “platinum device” and the silver standard was 875. Mostly “smooth” (without a pattern) objects were produced.

Small editions of items with a “pattern” were also produced, which are now quite rare. In the second half of the 40s - early 50s of the 20th century, the “Torch” series of products was produced in a fairly large edition, the most famous and popular to this day.

Kubachi Art Factory (Kubachi Jewelry Artel).

Kubachi art products are products of folk art craft that have existed for more than a thousand years. The assortment of Kubachi silver products is varied: cutlery, table spoons, dessert spoons, tea spoons, cup holders, glasses, shot glasses, mugs, shot glasses, various jewelry, household items and decorative items and many others. Kubachi silver products are characterized by niello on silver, which covers the product and is usually combined with carvings, engraved ornaments, gilding, filigree, filigree, embossing, gold notching, carved bone, colored enamel or, as they used to say, enamel.

Volnyansky plant named after. Shevchenko.

The plant dates back to 1870, when it was built by the German colonist Klassen together with the landowner Krivoshey as a factory for the production of agricultural machinery. Soon the stamping department of the plant was repurposed for the production of tableware “products of cupronickel and applied silver.” In 1891, the plant became the property of Klassen's son-in-law Heinrich Neufeld, who recruited the best craftsmen of that time to work on the production of exclusive silver cutlery. It was during this period that real masterpieces with original artistic design were created.

In 1920, the enterprise was nationalized by the new government and received the name “Agricultural Machine-Building No. 10”; production of silverware ceases. In 1926 it was renamed “ZiSh”. And only a year after returning from evacuation, in 1946, the plant began reconstructing production buildings and installing equipment for the production of cutlery and metal utensils. Using experience and not forgotten traditions, the enterprise achieves significant results and becomes one of the largest in the USSR in this industry. During the post-war years, the plant produced more than 10 million units of products. Today it produces products under the SRIBNA POLYANA trademark - cutlery made of silver-plated cupronickel/nickel silver (MNC).

Kolchuginsky plant named after. Sergo Ordzhonikidze

The oldest enterprise in Russia, founded back in 1871 by merchant Alexander Grigorievich Kolchugin, it remains a successful, stable city-forming enterprise to this day. The products of the consumer goods workshop of the Kolchuginsky Plant have always enjoyed increased popularity. Starting with the production of the then “Kolchugin Partnership” of cutlery, glass holders and dishes made of cupronickel; and to this day, when the latest high-precision equipment makes it possible to produce cutlery of the highest class, the number of fans of these products not only does not decrease, but rather increases.

Rezhevsky Mechanical Plant (Rezh Plant)

The company was founded in 1773 and during its existence it was awarded many different awards, including the Order of the October Revolution; The plant was also an indispensable assistant during the Great Patriotic War, producing products for the needs of the front.

RMZ has always been distinguished by the fact that it produced products that were relevant and competitive; unfortunately, in 1993, the plant stopped producing cutlery from nickel silver.

The mark of the ICJ (as well as ACC, KKM and MK)

The mark of the ICJ (as well as ACC, KKM and MK)

Post by Helga » May 15, 2013, 11:09 pm

Back in 2011, at Antique they raised the topic of the ICJ and MK stamps with a number. About the MK with numbers on the scanned glass holders, we found out that they belong to the Krasnoselsky jeweler.

But information on the ICJ mark remained unresolved. We are talking about such famous coasters (may Tomasol forgive me, I borrowed his photo):

Some of them bear the marks of the ICJ. On some - MK with numbers.

I remember back then they were still wondering what MK means - Krasnoselskaya copper?

.

Recently, a solution to this riddle suddenly came up.

Everyone knows that if a glass holder is made of silver, then it has an hallmark. If not made of precious metal, then sometimes the manufacturer next to the nameplate put a mark indicating the material: nickel-metal, brass, steel, metal, and sometimes to the nameplate of the enterprise simply added the letter “m”, which also means “metal”. I think we have just such a case. True, the letter “m” is not written as usual at the end of the name, but at the beginning. That is, in the MKJ and MK stamps the letter “M” means “metal”. Have you guessed what the other letters mean?

First, let’s remember the main dates in the history of Krasnoselsky Jeweler (information from the company’s website - https://www.krasnoselsk.ru/company/history/)

The history of OJSC "Krasnoselsky Jewelryprom" began in April 1919, when the production association "Krasnoselsky Labor Production Artel of Metal Products", better known by the name "Red Handicraft", was created.

In 1955, the “Red Handicraftsman” artel was renamed into the “Krasnoselsky Jeweler” artel (according to another version - “Red Jeweler”). With this name it will exist until 1960. Let us pay special attention to this.

In 1960, the Krasnoselskaya Jewelry Factory was organized, which included the Metalist, Krasny Jeweler and Promkombinat industrial markets.

In 1973, the jewelry factory was renamed Krasnoselsky Jewelry Plant, which in the same year became the parent enterprise of the Yuvelirprom production association.