Try asking your child what a tear is. Most likely, you will find out that “a tear is just when we cry.” Meanwhile, not every adult knows: a tear is far from “simple” and, in addition, tears are always present in the eyes, and not just when crying.

The human lacrimal apparatus is a tiny irrigation and drainage system. In a very limited volume near the front of the eyeball, tear fluid must somehow be produced, perform its functions and be discharged along certain drainage paths. Let's try to figure out how this happens.

Where to begin? From the basics

To begin with, look at what types of hallmarks there are and what they mean in the article by TD Serebro about silver.

Each piece of jewelry made of precious metal manufactured and sold on the territory of the Russian Federation is required by law to have two imprints:

- hallmarks of the Russian State Assay Chamber (from 2021 - Federal Assay Chamber);

- birthday boy.

The content of precious metal in the alloy is controlled by the state. It is regulated by Decree of the Government of the Russian Federation dated May 6, 2021 N 394 “On testing, analysis and branding of jewelry and other products made of precious metals.” Products made of precious metals manufactured in the Russian Federation, as well as imported for sale, must be marked with a state hallmark and comply with the Russian hallmark system.

The testing and hallmarking procedure is carried out by the Russian State Assay Office under the Ministry of Finance of the Russian Federation.

Most popular samples

Most jewelry is marked with the following hallmarks: 375, 500, 585, 750. 375 gold is considered low-grade. This product usually has a yellow or reddish tint and fades over time.

The middle group (500 and 585 samples) is the most popular. This ratio of precious metal and alloy in the alloy makes the item durable and durable without losing its external shine.

Jewelry of 750 standard is considered high quality. The alloy has a bright yellow color. Even in white gold, the golden yellow is clearly visible. The 750 alloy alloy usually contains other precious impurities - silver, palladium, platinum.

958 gold is rare. Such jewelry is soft and easy to deform. For minting coins, 900 standard is usually used.

What should the brand and name tag be?

The state assay mark is a special imprint that is applied by the state inspectorates of the assay supervision of the Russian Federation. It means that the product has been inspected by the inspectorate and has a grade not lower than that indicated in the stamp.

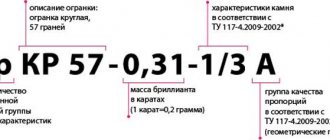

The state hallmark consists of an identification mark and an assay mark , which can be affixed together (in one image) or separately.

Since 1958, the ID badge has been an image of a hammer and sickle against the background of a five-pointed star. This sign is still in use today. Since 1994, an identification sign has been installed, representing a female head in a kokoshnik turned to the right in profile.

The hallmark is numbers showing the number of weight units of the precious metal in a thousand weight units of the alloy. If you see 925 purity, it means that there is 0.925 grams of pure silver per gram of the item.

The hallmark guarantees that the product has passed the test, and the content of precious metal in the alloy is not lower than the declared standard.

Development of a new stamp system

Until 1927, silver hallmarking in the USSR was carried out according to the rules introduced by the assay regulations of Tsarist Russia. The document was adopted in 1896, but became mandatory three years later. The purity of the silver was certified by a mark in the form of a female head in a kokoshnik, enclosed in shields of various shapes - round, rectangular, oval or in the form of a hammer. Next to the image a number indicating the sample was placed, and the first letters of the initials of the head of the assay district could also be placed. In 1908, changes were made to the marking - the female profile was turned to the right, and the district began to be designated with a Greek letter.

Pre-revolutionary brands were used at all enterprises that opened after the October revolution. In 1918, a platinum plant opened in Moscow, created on the basis of the former factory of I.P. Khlebnikov, it produced products intended for the needs of the chemical and electrical industries, as well as a small amount of silver tableware - spoons, forks and cup holders. The products were additionally marked with the “Platinopribor” mark.

Handicraft jewelry workshops were engaged in the production of jewelry in the 1920s; their number increased after the People's Commissariat of Finance allowed the free sale of jewelry. In 1923, the Moscow Jewelry Partnership (MJT) was organized, which was entrusted with the responsibility of monitoring the production and sale of items made of gold and silver. All products of the period 1923-1926 came out with the “MuT” marking.

After the revolution, for a long time there were only three assay offices - in Moscow, St. Petersburg and Kostroma; after 1924 their number increased to fourteen. Precious metals began to be weighed and counted in metric units instead of spool units, and silver standards changed from double-digit to triple-digit.

In 1927, a new branding system was adopted, which remained in effect for the next thirty years. Silver items produced in the country met the same requirements: they corresponded to an officially established standard and were marked with the mark of a specific assay inspection institution. The authenticity of the product was certified by a relief or linear image of the profile of a worker holding a hammer on his shoulder. The organization code was added to the drawing - each assay office was assigned a specific letter of the Greek alphabet, which was sometimes replaced by symbols in various combinations.

In 1936, the All-Union Office was created to regulate the sale and production of jewelry, replacing Mostorg. Jewelry factories opened in the capitals of the Union republics, marking their products with brand marks. Artels and industrial plants, which appeared in large numbers in the 1930s, acted in the same way.

Since 1953, the last digit of the year of manufacture of the product began to be added to the manufacturer’s name. For example, the combination “TZ0” meant that the item was made at the Tallinn Jewelry Factory in 1960. In cases where the letters in the names of enterprises were the same, to determine the place of production it was necessary to look at the code of the assay inspection.

Important Details

There are three ways to apply impressions:

- impact - applied mechanically to the stamp matrix;

- electric spark - applied with special equipment, the contour is not completed;

- laser - applying an imprint using laser engraving.

In Russia, the metric system of gold and silver samples has been adopted. The fineness of the alloy determines its value - the more precious metal, the more expensive. The remaining components (copper, zinc, nickel) are used to give the alloy strength and wear resistance, as well as some color. The color of the alloy does not depend on the standard: for example, 585 gold can be red, yellow, white and other colors, depending on the combination of alloys used.

The law does not require the marking of jewelry weighing up to three grams. Therefore, if you suspect that you have been sold a counterfeit item due to the lack of a stamp, first weigh the jewelry.

Anatomical sections of the lacrimal apparatus and clinical methods for assessing their functional state

There are two main structural elements: tear producing and tear draining. From school we remember that “tears are produced by the lacrimal gland,” but this knowledge is incomplete and insufficient. The fact is that the composition of the tear fluid is very complex and must be clearly balanced, since it performs a number of difficult-to-combine functions simultaneously: wetting the anterior surface of the eyeball (which is especially important for the transparent cornea, which would otherwise dangerously dry out when interacting with air oxygen), aseptic removing trapped particles, minimizing friction during movements of the eyeball and, at the same time, protecting tissues from waterlogging and “souring.”

Therefore, the composition of tears includes not only the liquid fractions themselves, but also oily-mucous, hydrophobic ones, and separate structural parts of the tear-producing section are responsible for their secretion. In addition to the main lacrimal gland, located above the eye from the side of the temple, there are also additional lipid and mucin glands of the conjunctiva, the mouths of which extend onto the inner surface of the eyelids adjacent to the eye.

Mixing and uniform distribution of various fractions of tear fluid over the surface of the eyeball occurs when blinking, ensuring constant renewal of a thin, but multi-layered tear film, which protects the cornea, sclera, and conjunctiva from the problems described above. Considering the mobility of the eyeball and the unreliability of surface tension, the film must be renewed quite often: otherwise, tears will appear in it (the fabric dries faster in these areas) and, in addition, the film itself quickly evaporates. Therefore, you should not suppress the natural blink reflex and read these lines, as they say, with an unblinking gaze - it is no coincidence that any system of eye gymnastics for people who constantly work with a computer necessarily includes breaks with intense blinking.

Having given way to a new portion, the waste tear fluid must, of course, go somewhere, otherwise the person would cry for days on end. On the inner wall of the eyelid, at the bridge of the nose, there are drainage entrances to the lacrimal canaliculi, where excess moisture flows. Getting into the so-called lacrimal sac, through the nasolacrimal duct, the liquid is discharged into the nasal cavity, where it is used for additional wetting of the nasal mucosa.

In Vasmer Max's dictionary

The mark is also glued, arkhang. (Under.); brand, ukr. stamp, glue, blr. brand, glue. Borrowing from it. *kleim, other - English. clám, English слоам, Middle-German-German klēm “glue, cement mortar, plaster”, Middle-German, Old-German. kleimen “to lubricate, smear” (see glue); see Bernecker 1, 511. Not from ancient history. kleima (contrary to Matzenauer 205; Mi. EW 119; see Törnqvist 10; Mikkola, Berühr. 1, 75), and also not from the modern-century. Kleinod "treasure, jewel" (contrary to Mikkola, ÄB 101). stamp on a silver bar" from Middle German kleinôe, kleinôde. – T.)

Application methods

The type of application may vary based on the following characteristics of the product:

- complexity of the work;

- features of the location of stones (if any);

- appearance;

- design.

There are the following methods.

Mechanical

It is considered a rough method, which is based on fixing the mark using physical pressure. It will require the use of a vice in which the product is secured, as well as jackhammers. The method is considered old; it was used back in the 17th century.

The advantage of mechanical application lies in the good quality of the applied sign: it will not be erased after some time and does not harm the decoration. Using this method, the mark is applied to 80% of products.

Electrospark

Allows you to apply the mark more subtly. Due to this, the design with the text is applied carefully by burning. Can be used even on fragile or very small jewelry. Used since 1967.

Laser

The work involves laser installations. The engraving is small and almost invisible. The brand is distinguished by its durability and endurance. However, we should immediately note the low productivity of this method. The laser will not be able to brand more than 600 products. Among the advantages is the flexibility of this method: the stamp is applied to any side of the decoration.