General information

Zirconium (Zr) is an element of the periodic table whose atomic number is 40 and its atomic weight is 91.22. In normal condition and under normal conditions, this material is a shiny metal with a silvery-white tint. The density of such raw materials reaches 6.45 g/cm3. This metal in its pure form, containing no impurities, is distinguished by the fact that it has very high ductility and is very easy to process, both cold and hot. It is worth noting here that this raw material, like titanium, for example, will sharply lose its mechanical properties if it is combined with impurities of non-metallic substances. The worst combination is zirconium and oxygen.

Material and alloy properties

Zirconium itself stands out because it has a fairly high resistance to various acids. This raw material does not dissolve in environments such as nitric and hydrochloric acid or alkalis. This characteristic is key. Based on it, many zirconium alloys are created. For example, if you take multicomponent magnesium alloys and add an element such as zirconium to them, the material will become much more resistant to corrosion. If you create an alloy of titanium and zirconium, the acid resistance of the first element will increase.

It is also worth noting that all zirconium alloys with other metals are characterized by the fact that they do not lose their viscosity over a wide temperature range; resistance to mechanical impact loads remains at a very high level. An example can be given of an alloy of magnesium with a few percent of zinc and only a few tenths of a percent of zirconium. The resulting metal will be almost twice as strong as simple magnesium, and it will also be able to maintain its strength at temperatures up to 200 degrees Celsius.

A1. what is the alloy: 1) nickel 2) zirconium 3) bronze 4) iron

A2.

which alloy does not contain Fe: 1) cast iron 2) steel 3) damask steel 4) nichrome A3. what is found in nature in a native state: 1) aluminum 2) gold 3) magnesium 4) zinc A4. in which process is reduction used: 1) pyrometallurgy 2) hydrometallurgy 3) electrometallurgy 4) in all processes B1. Match: A) aluminum B) copper (||) C) iron D) gold 1 solution of sulfuric acid, 2 water, 3 solution in hydrochloric acid, 4 solution in alkali, 5 solution in nitric acid, 6 solution in sodium cyanide 1 ) 3 2) like 4 3) 2 4) 4 В1 А4 B1 В2 Г5,1 (not quite sure about D) That’s it)

Description of characteristics

Zirconium alloys are most actively used in such areas as fuel rod cladding, fuel channel pipes, and various fuel assembly parts. Zirconium itself is also characterized by the fact that the neutron absorption cross section is quite low. In this indicator, it is second only to substances such as magnesium and beryllium. In addition, the melting point of zirconium is very high.

Zirconium alloys, used in various industries, are characterized by the fact that they have very high corrosion resistance in water, in a steam-water mixture, in saturated and superheated steam up to a temperature of approximately 350-360 degrees Celsius. It's also worth noting that this temperature limit is expected to be raised to higher values in the near future.

Mechanical properties of zirconium alloys

Zirconium alloys,

-based alloys

.

Until the beginning of the 50s. 20th century C. s. were studied little and were practically not used, and the information obtained at that time about their properties was in many cases unreliable, due to the use of insufficiently pure zirconium for research and imperfect methods for preparing alloys. The situation changed dramatically when in the early 50s. It was possible to obtain zirconium purified from hafnium impurities, and it was discovered that such a metal has a small thermal absorption cross section.

| Semi-finished product (condition) | |||||||

| tensile strength sВ | Relate- Body elongation d % | tensile strength sB | Relative elongation tion d % | ||||

| Mn/m2 | kgf/mm2′ | Mn/m2 | kgf/mm2′ | ||||

| Zircaloy-2 | Sheets (annealed) | 480 | 48 | 22 | 200 | 20 | 35 |

| Zr2.5Nb | Same | 450 | 45 | 25 | 300 | 30 | 23 |

| Zircaloy-2 | Pipes (cold rolled) | 690 | 69 | 22 | 400 | 40 | 19 |

| Zr2.5Nb | Same | 790 | 79 | 27 | 560 | 56 | 23 |

neutrons. This made it possible to consider zirconium (in the presence of other favorable properties) as a very promising material for the design of power nuclear reactors using thermal neutrons. However, as the first studies showed, it was not possible to use unalloyed zirconium for this purpose, primarily due to its unstable corrosion resistance in heated water. This circumstance stimulated the beginning of intensive research into alloys, which resulted in the development of industrial alloys that have found wide application in nuclear power. C. s. are used for structural elements of the active zone of nuclear reactors using thermal neutrons—cladding of fuel elements (fuel elements), channels, cassettes, spacer grids, etc. The greatest use of central heating systems. obtained in reactors with steam-water coolant. C. s. along with a small thermal neutron absorption cross-section, they have high and stable corrosion resistance in water and high-parameter steam and other aggressive environments, good ductility and satisfactory strength characteristics. To the alloying elements of C. s. a set of requirements is presented: some of them must significantly weaken (suppress) the harmful effect of nitrogen on the corrosion resistance of zirconium (with the permissible nitrogen content in alloys less than 0.01%), others must not significantly increase the cross-section of thermal neutron absorption, not reduce radiation resistance, increase strength characteristics without significantly reducing ductility (the alloys must be suitable for the manufacture of especially thin-walled pipes and sheets and have good weldability). Therefore, the choice of alloying additives is limited to a relatively small number of elements with a low content in alloys. For alloying, Nb, Sn, Fe, Cr, Ni, Cu and Mo are used, which are introduced in quantities from fractions of a percent to 2-3% (in total).

Of the large number of studied C. s. Only a few have found practical application. The American alloy Zircaloy-2 (1.5% Sn, 0.1% Fe, 0.1% Cr, 0.05% Ni and no more than 0.01% N) is most widely used abroad. The alloy Zircaloy-4 is also used (it differs from Zircaloy-2 in its lower nickel content - 0.007%). The Zircaloy-2 alloy was specially developed and was first used for fuel rod cladding of the reactor of the first American nuclear submarine Nautilus, then it found application in many power reactors of nuclear power plants for fuel rods and channels operating in water and steam-water mixtures at a temperature of 250-300 ° C . In the USSR, original alloys that do not contain tin have been developed and used - Zr1Nb and Zr2, 5Nb (with 1 and 2.5% Nb, respectively). The Zr1Nb alloy was first used for fuel rods of the reactor of the nuclear icebreaker "Lenin", and the Zr2, 5Nb alloy was used for the reactor cassettes of the Novo-Voronezh NPP. In the mid-70s. Zr1Nb and Zr2, 5Nb alloys are used for fuel rod claddings, cassettes and reactor channels of most nuclear power plants in the USSR and socialist countries. In addition, the Zr2, 5Nb alloy is used in a number of reactors in Canada. In terms of corrosion resistance, the Zr2, 5Nb alloy is comparable to alloys of the Zircaloy type, however, it has a lower tendency to hydrogenation, is not subject to a decrease in corrosion resistance under irradiation, and has greater strength, in particular, higher creep resistance. Despite the high melting point of zirconium (1852 °C), its known alloys do not have high heat resistance and are practically suitable for use in steam-water environments at temperatures no higher than 400 °C. At higher temperatures, along with a decrease in the strength of the central steel. strong oxidation occurs with the dissolution of oxygen, leading to loss of plasticity and hydrogenation, which causes embrittlement as a result of the formation of hydrides. Mechanical properties of C. s. such as zircaloy and zirconium-niobium alloys, the level of strength and ductility (during short-term tests) is of the same order (see table) and depend, as for other metallic materials, on the structural state caused by heat and deformation treatment.

C. s. melted in vacuum arc furnaces with a consumable electrode and electron beam furnaces. The so-called zirconium is used. nuclear purity (significantly purified from hafnium and other impurities with a large thermal neutron absorption cross section). Semi-finished products from C. s. are produced on conventional equipment used for many non-ferrous metals. Annealing is carried out in vacuum furnaces. If in nuclear energy C. s. became widespread, they found practically no application in other areas of technology; in particular, as a structural and corrosion-resistant material they are inferior to stronger, lighter and cheaper titanium alloys.

Lit.:

Metallurgy of zirconium, trans. from English, M., 1959; Proceedings of the Second International Conference on the Peaceful Uses of Atomic Energy, Geneva, 1958. Reports of Soviet scientists, vol. 3, M., 1959, p. 486; Rivkin E. Yu., Rodchenkov B. S., Filatov V. I., Strength of zirconium alloys, M., 1974; Douglas D., Zirconium Metallurgy, trans. from English, M., 1975 (lit.).

A. A. Kiselev.

Table of contents

Alloy parameters

The properties of zirconium alloys in terms of mechanical stability are quite high, which cannot be said about pure zirconium. It is alloying that achieves high strength of the material. For example, an alloy such as niobium (Nb) and 1% zirconium (Zr) will be characterized by the fact that the yield strength of the material at temperatures of 20, 200, 300 and 400 degrees Celsius will be equal to 200, 160, 120 and 90 MPa. This alloy is actively used for fuel cladding. And, for example, if you change the composition of a zirconium alloy with niobium, that is, increase the zirconium content to 2.5%, then the yield strength will increase to 280, 220, 200 and 180 MPa, at the same temperatures.

However, such materials also have their drawbacks. The disadvantages include the fact that the alloy with zirconium turns out to be too creeping when the temperature reaches 320-350 degrees Celsius and above. Another disadvantage is that Zr actively dissolves hydrogen, which often occurs during the corrosion process. Because of this, substances such as zirconium hydrides will be formed, which greatly reduce the ductility of the raw material, which makes the metal more brittle.

Review of titanium-zirconium (TC) alloys for use in endosseous dental implants

Dental implants made from binary titanium-zirconium (TC) alloys have proven to be highly durable, serving as a biocompatible alternative to pure titanium, especially in cases requiring the use of small-diameter implants. The purpose of this review is to summarize the existing literature covering the use of binary TC alloys for endosseous dental implants, tested in vitro, in animals, and in clinical settings.

And, moreover, to show that from the point of view of biocompatibility and osseointegration, the TC alloy is in no way inferior to pure titanium. Of the twelve references that met the included criteria, current literature supports the notion that small-diameter implants produced from TC alloys have 40% greater strength than implants that were produced from cold-processed Grade IV titanium. At the same time, the corrosion resistance and biocompatibility of these alloys are not inferior to those of pure titanium. The surface structure of TC alloys is comparable in supporting osseointegration to standard surface treatment methods for titanium implants. In addition, good osseointegration and high healing rates of implants made from binary TC alloys have been confirmed by studies conducted in animals as well as in clinical settings.

Introduction

Today, titanium (Ti) remains the main material for the manufacture of dental implants used in the treatment of patients with partial or complete loss of teeth [1–3]. This is partly due to the high resistance of titanium to corrosion both in air and in contact with biological fluids, as a result of which an oxide film is formed on its surface, thus making the material biocompatible. Its mechanical characteristics, including the optimal strength-to-weight ratio and ease of processing, also contribute to its widespread use in implantology. Moreover, titanium promotes osseointegration with the surrounding bone, and it is this quality that makes it successful in dental and orthopedic implants [4].

The use of commercially pure titanium (Ti) dental implants has a long history, dating back to 1965 with the work of Brånemark [5]. However, in some situations, the mechanical-elastic properties of Ti are insufficient. For example, in the case when implantation of one tooth is required or the implant must be installed in a very narrow edentulous ridge and a small (≤3.5 mm) diameter implant is required [6–8]. Unfortunately, a reduced diameter implant is associated with an increased risk of cracks and fractures associated with “material fatigue” [7, 9, 10]. As a result, there has been an incentive to create small diameter implants (SDIs) from titanium alloys with increased mechanical strength and elasticity. Among Ti alloys, the titanium-aluminum-vanadium alloy known as Ti-6Al-4V, which has widespread aerospace applications due to its improved strength-to-weight ratio, has been and remains the most commonly used in the industrial production of dental implants [11].

Due to the fact that there is no metal or alloy that is absolutely free from corrosion, it is necessary to take into account the corrosion characteristics of implantation materials, as well as study their possible toxicity [12, 13]. For example, the biocompatibility of Ti-6Al-4V is still questionable due to reports that the gradual release of aluminum ions, and especially vanadium, from the surface of Ti-6Al-4V can cause a local negative tissue reaction as well as a reaction from the body. immune system [2, 14, 15]. Thus, the search for a non-toxic, high-strength titanium alloy for medical applications is still ongoing.

As an alternative, Ti-6Al-7Nb, an alloy of titanium, aluminum and niobium, was proposed. This alloy maintains the strong microstructure of Ti-6Al-4V and replaces vanadium with non-toxic niobium. Although such a structure imparts strength to such a biomedical alloy, it should not be forgotten that there are also mechanisms for chemical etching of Ti that provide changes in surface roughness to improve osseointegration [17]. Moreover, titanium alloys containing non-toxic elements such as zirconium (Zr), niobium (Nb), tantalum (Ta), palladium (Pd) and indium (In) also continue to be researched for their ability to meet mechanical strength and corrosion resistance Ti-6Al-4V with increased biocompatibility [13, 18, 19]. In particular, when interacting with biological fluids, alloys with zirconium demonstrated both the necessary mechanical strength and high corrosion resistance [13, 17, 19]. The biocompatibility of TiZr-based alloys is higher than that of Ti [20, 21].

As stated above, along with the choice of material for the implant, an important aspect that ensures the success of implantation is also the topography and chemical composition of the surface. The positive effect of surface topography on osseointegration, achieved through methods such as metal blasting, sandblasting and acid etching, has been the subject of research for several decades. Micro-roughened surfaces currently dominate the market: they provide accelerated bone integration, a higher percentage of bone-implant contact (BIC) and increased resistance to deformation, as determined through torque performance (TMR) when compared with polished or polished titanium implants. machined surface [22]. The combination of sandblasting and acid etching of the surface of titanium implants, known as SLA® surface finishing (Institut Straumann AG, Basel, Switzerland), has been tested in both animal and clinical settings and has provided results confirming the ability of the relief to enhance osseous integration and provide long-term stability [23–27]. In addition, it has been demonstrated that hydrophilic surfaces can be osteogenic, thereby influencing the maturation and differentiation of bone cells [28, 29]. Accordingly, in order to enhance the surface energy, a hydrophilization technique called SLActive was added to the above-mentioned SLA® treatment [30]. This treatment, which involves flushing micro-rough surfaces with nitrogen and storing them in a saline solution instead of air, was used to improve the initial wet conditions, reducing the risk of contamination while maintaining a more active titanium surface. The beneficial effects on cell differentiation and growth factor in SLActive-treated titanium implants compared to SLA-surfaced Ti implants have been confirmed in vitro, in animal studies, and in clinical studies [31–33]. Interestingly, along with increased wettability, there is evidence that nanostructures spontaneously forming on SLActive surfaces may also contribute to a more active bone response [34]. When studying new alloys with increased mechanical strength, it would be optimal to preserve the micro-rough relief and hydrophilic properties of the surface, which can rightfully be considered an integral element of the engraftment of Ti implants. In this respect, the binary TiZr alloy stands apart from other alloys because it maintains a similar Ti structure and is suitable for both SLA and SLActive processing [17]. As a result, TiZr is an attractive material for implant fabrication, especially for small diameter implants (SDIs), due to its increased strength while possessing the biocompatibility and osseointegration properties of Ti. Therefore, the purpose of this study is to summarize the existing literature (from 1987 to April 2012) on the use of binary TiZr alloys in endosseous dental implants tested in vitro, in animals and in clinical studies. And furthermore, demonstrate that TiZr is as good as the gold standard, Ti, in terms of biocompatibility and osseointegration.

Methods

In order to analyze all the reviewed literature regarding in vitro, animal and clinical studies of binary TiZr alloys, a systematic approach was used to search and study sources for the period from 1987 to April 2012 through the PubMed search engine.

results

Of the twelve articles that met the criteria, four were devoted to in vitro and/or studies of the mechanical characteristics of TiZr [17, 19, 29, 35], five were devoted to the functioning of TiZr implants in animals [21, 36-39], and three analyzed clinical results of TiZr dental implants [6, 40, 41]. The results of these studies are summarized in tables No. 1-3.

Table No. 1. In vitro studies of TiZr dental implants

First author, year | Type TiZr | Study details | Main results |

| Sista and his research group, 2011 [29] | TiZr (50% Zr) | TiZr was compared to Ti and TiNb by cell assay using mouse osteoblast cell chain (MC3T3-E1) and surface characteristics. | More cells attached to TiZr than to Ti or TiNb, although the sputtering was the same. TiZr and Ti showed higher alkaline phosphatase (ALP) activity and osteocalcin (OC) index than TiNb, indicating cell differentiation. |

| Bernhard and his research group, 2009 [17] | TiZr* (13-17% Zr), SLActive® | TiZr was compared to Ti cell assay using osteoblast-like MG-63 cells. | TiZr is compatible with the SLActive surface treatment method used for Ti. It was found that TiZr has similar biocompatibility to Ti. The tensile strength and 0.2% yield strength were, respectively, 40 and 60% higher than these parameters for Ti. |

| Zhang and his research group, 2009 [19] | TiZr (12% Zr) | TiZr was compared to Ti, Ti6Al4V, TiAlMoZr, TiNbTaZr and stainless steel cell assay using human lymphocytes (HEM) and MC3T3-E1 cells. | In the presence of cells and various electrolytes, titanium alloys containing zinc showed the highest corrosion resistance. |

| Kobayashi and his research group, 1995 [35] | TiZr (0-100% Zr) | TiZr was compared with Ti-6Al-4V and Ti-Zr 6Al-4V. | At 50% Zr content in Ti, the hardness and tensile strength increased by a maximum of 2.5 times. An increase in the hardness of TiZrAlV compared to standard TiAlV was also found. |

*Known in the industry as Roxolid® (Institut Straumann AG, Basel, Switzerland) for IMD.

Table No. 2. Animal studies of TiZr dental implants

First author, year | Type TiZr | Study details | Main results |

| Saulacic and his research group, 2012 [37] | TiZr* (15% Zr), SLActive ® | TiZr was compared with Ti and Ti6Al4V in mini pigs for 1, 2, 4 and 8 weeks. | The compared indices of bone-implant contact (BIC) in TiZr and Ti increased from the 2nd to the 8th week. In contrast, the FIR values for TiAlV were significantly lower. |

| Gottlow and his research group, 2011 [36] | TiZr* (13-17% Zr), SLActive® | TiZr was compared with Ti in minipigs over 4 weeks. | For TiZr, the torque values were higher and the bone zone was wider. For Ti and TiZr, the PVM was the same. |

| Thoma and his research group, 2011 [39] | TiZr* (15% Zr), SLActive® | TiZr was compared with Ti in dogs over 2, 4 and 8 weeks. | Safe healing, without any special incidents, was recorded for both TiZr and Ti implants. There was no difference at any time point for the CIC of approximately 80%. |

| Ikarashi and his research group, 2005 [21] | TiZr (50% Zr) | TiZr was compared with Ti and Cr plates in rats over a period of 8 months. | TiZr alloy exhibits better mechanical properties and biocompatibility than Ti. |

| Shibata and his research group, 1987 [38] | Porous TiZr (40% Zr), using 3 different particle sizes | On rabbits for 2, 4, 8 and 12 weeks. | Agglomeration of larger particle sizes resulted in better bone fusion, filling, and bond strength (as tested). |

*Known in the industry as Roxolid® (Institut Straumann AG, Basel, Switzerland) for IMD.

Table No. 3. Clinical studies of dental TiZr implants

First author, year | Type TiZr | Study details | Main results |

| Al-Nawas and his research group, 2011 [6] | TiZr* (13% Zr), SLActive®, 3.3 mm diameter | TiZr was compared with Grade IV Ti 3.3 mm in diameter and 87 patients with removable dentures were followed for 6 and 12 months. | Over 12 months, TiZr performs at least as well as Grade IV Ti, as measured by changes in bone levels, tartar levels, and marginal gingival bleeding. Implant survival rates were 96.6 and 94.4% for TiZr and Ti, respectively. |

| Barter and his research group, 2011 [40] | TiZr* (13-15% Zr), SLActive®, 3.3 mm diameter, splinted to a conventional Ti implant | TiZr was compared with Grade IV Ti with a diameter of 3.3 mm, and 22 patients were followed for 2 years. | This article reports the first clinical experience with TiZr implants of reduced diameter and confirms the validity of the concept, since all 20 implants successfully took root after 2 years. Level of bone change (1 mm) and pocket depth during probing meet established criteria for engraftment and durability. |

| Chiapasco and his research group, 2011 [41] | TiZr* (13-17% Zr), SLActive®, 3.3 mm diameter | The load on the prostheses was studied, and 18 patients were observed for 0 and 2-12 months. | Osseointegration of all implants and prosthetics were successfully completed. Bone resorption around the implant ranged from 0 to 1 mm. The degree of survival and durability was 100%. |

*Known in the industry as Roxolid® (Institut Straumann AG, Basel, Switzerland) for IMD.

Discussion

Mechanical characteristics and in vitro results:

The need for implants made of biomaterials with increased mechanical strength for both dentistry and orthopedics has led to the search for alternatives to Ti alloys that are free of toxic elements such as vanadium. In dentistry, the use of small-diameter implants would be useful in the situation of replacing one tooth or when it is necessary to install them in narrow ridges with complete loss of teeth. However, until now, their use has been limited to the “aesthetic zone” due to the risk of cracks and fractures associated with “material fatigue” under high functional load. The higher mechanical strength of Ti alloy for small diameter implants would eliminate the need for reconstructive surgery and/or bone grafting or augmentation in narrow ridges. Titanium-zirconium (TiZr) alloy is a promising material for such applications.

All short-term animal studies to date confirm that small-diameter TiZr dental implants (3.3 mm) perform just as well as Ti implants.

Clinical trial results:

Three clinical studies were conducted to examine TiZr implants versus Grade IV Ti (see Table 4 for comparative comparison).

Certainly, the results of these clinical studies [6, 40, 41] highlight the high patient survival rate of TiZr implants (ranging from 95.2 to 100%). TiZr implants met established dental implant survival and longevity criteria, demonstrating good osseointegration, acceptable levels of bone change, probing pocket depth, calculus, and crevicular bleeding. Based on these preliminary results, it can be assumed that the functioning of TiZr implants will be safe and reliable.

However, more long-term studies of TiZr as an implantation material, as well as on the survival of IMDs, are necessary before they can be recommended for clinical use without any restrictions.

Conclusion

A review of the existing literature showed that TiZr alloys have the same, and in some cases higher, biocompatibility than Ti. Moreover, TiZr's corrosion resistance is as good, if not better, than Ti; however, its α-phase crystal lattice indicates that surface treatment techniques that improve osseointegration of Ti implants can continue to be used with the new TiZr alloy.

And finally, the strength of TiZr implants is 40% higher than the strength of cold-processed Grade IV Ti, which makes the TiZr alloy a promising material for the manufacture of IMDs even at high functional loads. To date, few animal and clinical studies have been conducted on the performance of reduced-diameter (3.3 mm) TiZr implants in vivo. The results of these studies unanimously indicate that TiZr implants perform no worse than Grade IV Ti implants. In each case, good osseointegration and high survival rates were recorded for TiZr alloys. However, there is still a need for longer-term follow-up of TiZr implants, as a period of two years is the longest to date. In conclusion, in vitro, in animal experiments and in clinical settings, TiZr alloys have demonstrated the ability to perform as well as Ti, highlighting their priority as a material for implantation in the future.

The list of references is in the editorial office.

Zirconium in medicine

Zirconium alloys are used quite actively in medicine. Scientists have found through experiments that even wearing simple zirconium bracelets can help in the treatment of certain diseases, and this can also improve a person’s overall level of well-being.

Today, implants (fixators) are quite often used in such areas of medicine as traumatology and maxillofacial surgery. Fixators are used for fractures, fixing the bones so that they do not move. It is in these cases that one can highlight such advantages of using zirconium alloys as: high biological compatibility (meaning the absence of allergic reactions of the human body to such an alloy or rejection), high strength characteristics of the alloy, which is very important for fixatives. It is also worth noting that the absence of rejection or allergy to such a substance meant that there was no need to repeat surgery to remove the fixative if the body suddenly began to reject the implant.

Zirconium in nuclear energy

Until the 50s of the last century, it was believed that zirconium was not suitable for use in this area. However, it was in the 50s. For the first time, a material was obtained that was completely purified from such an impurity as hafnium. After purification, pure zirconium was found to have a very small thermal neutron absorption cross section. It was this quality that became the main one and made it possible to use zirconium alloys in nuclear energy.

It is worth adding that it was not possible to use simply purified zirconium due to the fact that the corrosion resistance was too low in hot water. After this, it was decided to use zirconium-based alloys. They have proven themselves to be excellent when used in reactors with steam-water coolant, as well as in other similar aggressive environments.

Zirconium and its alloys

PROPERTIES AND APPLICATIONS OF ZIRCONIUM

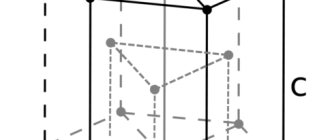

Zirconium (Zr) is one of the refractory elements. It was discovered in 1879. Its name comes from the name of the mineral zirconium containing the element. Zirconium exists in two modifications. Up to 863°C, modification α with a hexagonal close-packed crystal lattice is stable, and from 863°C to the melting point, modification β with a body-centered cubic crystal lattice is stable. During polymorphic transformations, a significant change in the volume of zirconium occurs. The physical and mechanical properties of zirconium are given below:

| Atomic mass | 91,22 |

| Density at 20°C, g/cm3 | 6,45 |

| Temperature, °C: | |

| melting | 1852 |

| boiling | 3580 |

| Specific heat capacity, cal/g | 0,0650 |

| Thermal conductivity coefficient at 20 °C, cal/(cm sec deg) | 0,04 |

| Linear expansion coefficient at 20 °C, 1/deg | 6,3*10-6 |

| Electrical resistivity at 20°C, Ohm*mm2/m | 0,044 |

| Modulus of normal elasticity, kg/mm2 | 9632 |

| Tensile strength, kg/mm2 | 17,5 |

Pure zirconium has very high ductility, which is maintained even at liquid nitrogen temperatures. However, the strength characteristics of zirconium are low. Impurities present in zirconium tend to increase its strength and reduce its ductility. The tensile strength and yield strength of zirconium sharply decrease with increasing temperature and become very small already at 500°C; at temperatures above 400°C, creep also develops intensively. The strength properties of zirconium are significantly increased by cold hardening. The strongest hardening during cold deformation is achieved at reduction rates of up to approximately 20%.

Compact zirconium has high corrosion resistance in many aggressive environments. It is not affected by concentrated hydrochloric and nitric acids, as well as organic acids, even when heated to 100°C. In terms of corrosion resistance in hydrochloric acid, zirconium is second only to tantalum and noble metals.

Zirconium is stable in hot concentrated solutions of caustic soda and has exceptionally high corrosion resistance at room temperature in ordinary and sea water. When heated, it is stable in water up to 360°C. At higher temperatures, the corrosion rate of zirconium increases greatly. Zirconium is unsuitable for long-term operation in water vapor at temperatures exceeding 427°C.

Sulfuric acid has a relatively weak effect on zirconium at a concentration of less than 70%, but with increasing concentration the rate of corrosion of zirconium increases sharply. Aqua regia, hydrofluoric acid and concentrated phosphoric acid dissolve zirconium. Chlorine and bromine waters quickly cause pitting corrosion of zirconium.

The corrosion resistance of zirconium sharply decreases under the influence of impurities: nitrogen,

carbon, titanium, aluminum. Iron, nickel and chromium increase the corrosion resistance of zirconium. Zirconium-tin alloys, additionally alloyed with iron, nickel or chromium, have very high corrosion resistance.

Zirconium interacts with gases at relatively low temperatures. It reacts most intensely with hydrogen. Zirconium powder or sponge absorbs hydrogen at room temperature. As the temperature rises, the rate of interaction between them increases. The absorption of hydrogen by zirconium is accompanied by a significant increase in the volume of the metal. At temperatures above 800°C, hydrogen can be almost completely removed from zirconium by vacuum extraction. Hydrogen dissolving in zirconium significantly reduces its impact strength at low temperatures. The hydrogen embrittlement of zirconium is detected already at a hydrogen content of 0.001%. Hydrogen embrittlement of zirconium is also observed after hardening from temperatures above 315°C and subsequent aging at temperatures below 260°C.

Powdered zirconium is very pyrophoric. Thin shavings and filings of zirconium ignite easily. If there is a certain concentration of zirconium dust in the air and a heating source, an explosion may occur.

Until recently, zirconium was used mainly in the form of compounds and alloying additives to alloys. A significant part of it was used for the production of high-quality refractories based on zirconium dioxide, which has a high melting point, as well as for the production of special types of porcelain, enamel and glass. In the form of metal powder, zirconium is used in explosives, incendiary and lighting mixtures, and as a getter in various electric vacuum devices. The high anti-corrosion properties of zirconium make it suitable for the manufacture of parts for chemical equipment and medical instruments.

In steel production, zirconium is used as a deoxidizing agent, degassing agent and alloying element. The addition of zirconium to chromium, nickel, manganese and other alloy steels dramatically increases their plastic properties; Zirconium steels are easy to weld.

Additions of even small amounts of zirconium or its compounds with fluorine to cast aluminum alloys make them fine-grained, increase ductility and strength properties. Additions of zirconium to magnesium and its alloys act in the same direction.

Alloys of zirconium and tungsten are used in vacuum lamps, which ensures greater heat resistance than when using tungsten, molybdenum, vanadium and a number of other metals.

The widest area of application of zirconium at present is in nuclear reactors, where it acts as the main structural material. This is due to the small thermal neutron absorption cross section of zirconium, combined with high corrosion resistance, high ductility and good machinability. In addition, due to the small modulus of elasticity and the extremely low coefficient of thermal expansion, the thermal stresses arising at high temperatures in zirconium are lower than in steel and a number of other materials.

For the manufacture of structural elements of nuclear reactors, zirconium alloys are most often used, along with beryllium. Alloying additives increase the strength and thermal stability of zirconium, and also neutralize the harmful effects of impurities. Typically, zirconium is doped with tin, aluminum, molybdenum and niobium, i.e., elements that have a relatively small thermal neutron absorption cross section.

Strength properties and creep resistance at high temperatures are most strongly enhanced by tin and aluminum, while molybdenum and niobium have a more vigorous strengthening effect at room temperature. Tin neutralizes the harmful effects of nitrogen and carbon on the corrosion resistance of zirconium when working in water and steam. This effect is enhanced by the simultaneous introduction of iron, nickel and chromium with tin.

Examples of industrial zirconium alloys for nuclear reactors are the Zircaloy-2 and Zircaloy-3 alloys.

General alloy applications

Zirconium is widely used as an alloying element. This is due to the fact that the metals to which this substance is added become more heat-resistant, acid-resistant, etc. That is, the alloy of metal and zirconium greatly exceeds the characteristics of the initial raw materials.

Ferrozirconium is quite widely used. It is an alloy of zirconium and iron. The content of the alloying element Zr reaches 20% of the total mass. This substance is used in metallurgy as a deoxidizer and degasser for steel. Aluminum-zirconium alloys, for example, are considered the most resistant to corrosion and are used in cathode grids for vacuum tubes. The Zr content in such an alloy is no more than 3% of the total mass.

In ferrous metallurgy, in addition to ferrozirconium, an alloy of Zr and silicon is often used. It is used for degassing steel. An alloy of copper and zirconium is widely used for the manufacture of conductive elements for electrical equipment.