History and description of the stone

This mineral was first discovered by the ancient Greeks in Magnesia, a coastal part of the historical region of Thessaly, on the coast of the Aegean Sea. Already in ancient times, different types of magnesite were used to produce refractory bricks necessary for the smelting of metals. The mineral was also used in jewelry.

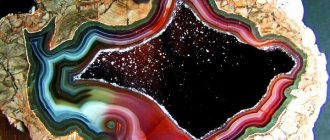

There are 2 types of magnesite stone depending on its origin:

- crystalline, shiny, transparent;

- amorphous, similar in appearance to marble, but less durable (comparable to porcelain), matte.

The first was formed as a result of the interaction of igneous rocks with hot fresh and salt waters in the Paleozoic and Precambrian eras. The second - later as a result of chemical weathering.

The main color is white (due to magnesium in the formula). Impurities of iron, calcium, manganese, nickel, and cobalt give the mineral yellow, pink, cream, brown, and greenish shades.

Areas of application

Magnesite rock is suitable for the production of building materials, including:

- refractory brick that can withstand heating up to 300°, which acts as a facing material for furnaces, protecting them from thermal and chemical influences.

- insulating mass for building boards with magnesite used for external and internal decoration,

- artificial marble slabs and decorative stone obtained from mineral caustic powder by pressing in combination with adhesive compositions,

- plasters with high resistance and increased technical service life,

- binding material - magnesite cement, which is used in the manufacture of grinding wheels,

In the chemical industry, magnesite ore and magnesium salts are produced from magnesite. Due to its fire-resistant properties, it serves as the basis for fire-resistant paint and varnish coatings and is a component in the production of electrical insulators.

In metallurgy it is necessary in the production of sulfuric acid. The refractory stone magnesite is used in the production of ceramic and glass products. In pharmaceuticals it acts as an analogue of talc. In demand in the rubber and paper industries.

Place of Birth

The largest deposits of magnesite are located in Russia. The world's largest deposit for industrial needs is Savinskoye in the Irkutsk region. Industrial development is carried out in the Volga region, Krasnoyarsk region, the Far East and the Urals. In the Satka deposits of the Chelyabinsk region there are not only industrial designs, but also crystalline ones used for jewelry purposes.

In addition to our country, magnesite is mined in:

- Greece;

- Poland,

- North Korea,

- USA,

- India,

- Australia,

- China,

- Austria,

- Czech Republic,

- Canada,

- Brazil.

INDUSTRIAL MINERALS

More than 90% mined magnesitefired tightly to produce refractory magnesia in the form of a loose granular product or in the form of molded bricks. These products are used primarily in the steel industry for the internal lining of main hearth furnaces and converters. In addition, magnesite refractories are used in copper smelting and cement furnaces, as well as other devices operating at high temperatures.

Refractory magnesia contains 4-5% iron oxide and approximately the same amount of silica, and in addition, minor impurities of alumina and lime. Fire bricks can be made from magnesia alone or from a mixture of it with other substances - chromite, silica or olivine. Sometimes fireproof magnesia can be replaced by tightly burned dolomite (p. 241).

Caustic magnesia

It is used for several purposes, but its most important use is as a raw material for oxychloride cement (Sorel cement). Finely ground magnesia mixed with a solution of magnesium chloride forms a viscous, dense cement, which is excellent for flooring in interior spaces, where the floors must be especially wear-resistant. This cement serves as a binder for “organic additives such as sawdust and cork, and has increased elasticity, resistance to abrasions, oils and acids, and is easy to saw and cut.

Mines of Stephens County, Washington

Bain (1924) identified four main types of magnesite deposits: 1) primary sedimentary; 2) products of alteration of serpentinites; 3) infill veins and 4) metasomatic formations in carbonate rocks. Currently, magnesite is mined in industrial quantities, mainly from deposits of the fourth type. One of the two main deposits of magnesite in the United States is located in Washington State, the other in Nevada.

Since 1916, large quantities of magnesite have been mined from deposits in Stephens County, in the northeastern part of Washington State (8.5) (Bennett, G941; Campbell, Loofbourow, 1946). The magnesite field is a northeast-trending belt 30 miles long and 2 to 7 miles wide located in the eastern foothills of the Huckleberry Mountains. The middle of this belt is about 40 miles northwest of Slocyne; at the northeastern end of the belt is the city of Chivila. Elevations range from 1,700 feet near the Colville River near Chiville to 5,700 feet in the higher elevations of the area a few miles southeast.

Magnesite deposits are confined to dolomites of the Stensgar formation, part of the Deer Trail group of late Precambrian age. The Deer Trail Group, which has a total thickness of 5 thousand feet, consists primarily of mudstone, slate, and quartzite. The deposits of this group are unconformably overlain by Precambrian conglomerates and greenshales, which in turn are overlain by quartzites, probably of Cambrian age. In the southwestern part of the belt there is an intrusive massif of Loon Lake granites of Cretaceous age.

Metasedimentary and greenstone rocks are intensely folded and form the northwestern wing of a large anticline, inclined to the northeast. In places the layers are overturned and drag folds develop significantly. Parts of the section repeatedly come to the surface, moving along meridional faults, which, according to Campbell and Loofbourow (1957), have a vertical dip. The alteration of rocks associated with folding and disjunctive tectonics in the vicinity of the Loon Lake granite massif is enhanced by contact metamorphism.

The sediments of the Stensgar Formation, about 600 feet thick, are typical dense, light-colored dolomites, locally recrystallized into coarser-grained metadolomites. The formation emerges on the surface in a series of elongated outcrops that can be traced throughout the belt. Magnesite forms irregular bodies in dolomites, which range in size from small lenses containing the first tens of tons of magnesite to large deposits with reserves of more than 1 million g. The grain size of magnesite ranges from fine to coarse, and the color varies from white through shades of gray and red colors to black. Magnesite impurities are represented by areas of unreplaced dolomite, as well as scattered grains of pyrite, quartz and silicates.

The development of a single and generally accepted point of view on the origin of magnesite was hampered by the complex structural and stratigraphic relationships of the rocks developed in the area. For many years, some geologists adhered to the idea that magnesite was formed by sedimentary sediments. However, as a result of recent studies, it has clearly become clear that magnesite is in incorrect secant relationships with the bedding surfaces of dolomite, bears relict features of the structure of the latter and arose as a result of its metasomatic replacement. Metasomatism is associated with hydrothermal solutions that split off from the granitic magma of the Loon Lake massif, which intruded after the deformation of the Deer Trail Group sediments. These solutions penetrated along bedding surfaces and along cracks in the dolomite, removing calcium and causing its replacement with magnesium.

Several large deposits

. The geological structure of one of them, the Turk deposit, was described by Bennett (1943), and the origin of magnesite was considered by Schroeder (1949). A geological map of the entire mining district of Stephens County, without an explanatory record, was published in 1957 (Campbell and Loofbourow, 1957).

When mining magnesite

Both open and underground mining methods are used. After crushing, the magnesite is sent through a conveyor to enrichment plants, where impurities are removed from it using flotation and separation in heavy media. The concentrate is then fired to produce refractory magnesia and sent to refractory factories. The correspondence of the name of the mountains to the essence of the matter (paradise, paradise) is very doubtful, since the climate here is desert, water supply is a difficult problem, and the vegetation is sparse. The deposits are located at an altitude of 5-6.5 thousand feet, the bottom of the Gabbs Valley to the west of the deposits has a hypsometric elevation of 4600 feet. Two miles west of the mines is the town of Gabbs, built on an alluvial fan. The deposits are connected to the Southern Pacific Railroad (at Luning Station) by a 29-mile paved highway. The city of Reno is located approximately 115 miles northwest of the fields.

Within the Gabb ore field there are, in addition, exploited deposits of brucite, the soft waxy translucent aggregates of which somewhat resemble talc. The first mineral of industrial interest discovered here was brucite (by prospectors in 1927); soon after this, the presence of magnesite was established. The MgO content in brucite is 69.0%, and in magnesite - 47.6%.

The Paradise Ridge is an inclined fault-type tectonic block (basin and ridge structure) surrounded by Tertiary volcanic rocks and Quaternary desert-alluvial sediments. The internal structure of this block reflects the complex history of its geological development. Permian (?) and Triassic stratified sedimentary and volcanic rocks underwent folding processes, were broken by disjunctive faults and were regionally metamorphosed. Then they were successively intruded by: 1) hundreds of small dikes and sills of diabases, aplites, rhyolites and other rocks associated with them; 2) several disconnected bodies of coarse-grained granites; 3) stocks and dikes of granodiorites. Under the influence of these intrusive bodies, the host rocks underwent contact metamorphism, superimposed on earlier regional metamorphism, and solutions separated from the intrusions led to mineralization.

Pre-intrusive west-to-east thrust movement had an amplitude of several miles. The metamorphism, intrusions and thrust movements are inferred to be Jurassic in age. Normal normal fault movements began before the formation of the thrust faults and then resumed periodically until the modern period. In post-Tertiary times, the ridge was involved in block movements and underwent prolonged uplift.

Magnesite and brucite are confined to the upper essentially dolomitic part of the Luning Formation (Upper Triassic). The dip of the rocks of this formation is predominantly western, moderate to steep, although there are local variations. The deposits are located near the granodioornth stock, which extends in a northwestern direction (8.6). All rocks of the ore field are confined to the hanging thrust block

Paradise, which comes to the surface about one mile to the east.

The dolomites of the Luning Formation are classified into three petrographic types, which are actually different varieties of metadolomites. The first of these varieties is dense, dark gray to black, fine-grained dolomite. It exhibits a parallel orientation of carbonate grains and minor amounts of tremolite; this rock is undoubtedly the product of dynamic metamorphism. The second type includes white coarse-grained dolomite, formed at the expense of dark dolomite as a result of thermal metamorphism. Whole strata and irregular large sections have undergone this type of recrystallization. The third type is gray medium-coarse-grained dolomites, which have a reddish-brown color on the weathered surface due to the presence of iron compounds. It is assumed that the iron was introduced by hydrothermal solutions and was deposited in the form of pyrite. Rocks of this type gradually transform into magnesitized dolomites and magnesites.

Gray medium-grained granodiorites at Gabbs form a very irregularly shaped stock that cuts recrystallized dolomites and magnesites. Thus, these latter were already present during the formation of granodiorites and should have been formed at an earlier time. Dolomite recrystallization and magnesite formation are thought to be related to the influence of coarse-grained granite intrusion, which, based on field relationships, predates the intrusion of granodiorite. Granites are not exposed in the Gabba region, but form a stock in the Broken Hills Range about 7 miles to the north, and also small bodies in the Paradise Range 2.5 miles southwest of the ore field.

Brucite cuts and replaces both magnesite and associated dolomites, developing in close contact with granodiorites. It can be assumed that it arose under the influence of hydrothermal solutions released from granodiorites.

The hydrothermal concept of the origin of magnesite and brucite was put forward by Callaghan (1933); recently it has been developed and substantiated (Vitaliano and Callaghan, 1956; Vitaliano et al., 1957). However, this concept is disputed by Martin and Willard (1957), who suggest that magnesite was deposited "in a sedimentary setting." Martin (1956) questioned the existence of a genetic link between magnesite mineralization and intrusions. In light of the overwhelming evidence provided by Vitaliano et al., this latter concept is difficult to accept.

Magnesite is present within a 1-mile, 3,000-foot-wide area located northeast of the granodiorite stock, but not all of the rocks developed here are ore. In fact, in this area all the gradual transitions from pure magnesite to pure dolomite are observed, with very bizarre and interpenetrating variety boundaries. Due to the great external similarity of the two carbonate minerals developed here, it is possible to distinguish them only with the help of chemical analyses. To reliably sample deposits, core holes must be spaced as little as 50 feet apart. There are three grades of magnesite based on CaO content: less than 5%, from 5 to 26% and more than 26%. These varieties are distributed both in plan and in section in a very complex manner. Magnesite has been drilled to a depth of 600 feet, the actual maximum depth of its occurrence is unknown.

Impurities in magnesites, in addition to dolomite, are represented by iron oxides and some silicate minerals. In addition, the magnesites are intersected by dikes of various igneous rocks. Dikes make operational work very difficult.

Magnesite is mined by two companies using conventional open-pit mining methods. Operational exploration is carried out by core drilling, and the boundaries of the distribution of qualified ore are determined by testing for lime and silica content. Based on testing data, plans for the distribution of lime and silica are drawn up. After clearing the bench in the quarry, the boundaries of standard mineralization are marked, which makes it possible to carry out selective extraction of material. The enriched material is fired to produce both caustic and refractory magnesia.

brucite

forms two deposits on opposite sides of the granodiorite body. Both of these fields are being developed, but most of the production comes from the eastern, or upper, field. The brucite deposit here is about 1,000 feet long and 200 feet wide. Brucite contains a huge amount of impurities and inclusions - relics of dolomite and magnesite, dikes and lens-shaped bodies of igneous rocks, as well as an abundant admixture of silicates. The cracks in brucite are filled with late dolomite. Methods for developing brucite are described by Holmes (1949). Brucite is sent to Ohio, where it is tightly fired with dolomite to produce high-temperature refractories.

During the Second World War, the Gabbian deposits were the source of raw materials for the world's largest plant for the production of magnesium metal. This government-owned plant was located near Las Vegas, Nevada, where electricity from the Hoover Hydroelectric Power Plant was abundant. The magnesium plant was closed in November 1944, having by that time produced 81,272 tons of magnesium metal from 920,000 tons of ore. There is a complete description of the technology of this production in print (Ball, 1944).

Other deposits

Sedimentary magnesite was discovered near Overton, Clark County, southern Nevada. It is interbedded with dolomite in the Horse Springs Formation of Miocene(?) age. This formation is somewhat dislocated and lies at a dip of 25-40°. Both magnesite and dolomite have a brilliant white color; Both are soft and have the consistency of clay. Rubey and Callaghan (1936) believe that this sequence was deposited in a playassic (desert) lake. About 120 miles further south, near Needles, California, another sheet magnesite deposit is located (Vitalian Oj 1950). Here the magnesite forms lenses 12 feet thick, 600 feet wide, and 2,400 feet long in Tertiary sediments that have undergone marked folding and are broken by normal faults. It is assumed that magnesite is of continental-lacustrine origin. A possible source of magnesium is considered to be waters that are genetically related to the Tertiary volcanoes of the region and probably came in the form of hot springs. Sedimentary magnesite in the United States is of only potential industrial importance. It is also assumed that very large deposits in northeast China are of sedimentary origin (Nishihara, 1956).

Magnesite associated with serpentinites is established in many places in the pre-Cretaceous ultramafic complex of the Coast Range and western Sierra Nevada of California. These deposits are small, but the magnesite in them is extremely pure. Due to the latter circumstance, as well as due to the proximity of the industrial areas of the Pacific coast, Californian magnesite deposits were intensively developed during the Second World War. Most of them are now depleted. The largest deposit of this type is located at Red Mountain within Santa Clara and Stanislau counties, in the Coast Range, about 60 miles southeast of San Francisco. Here there is a complex sill-like body of peridotites and associated rocks, altered into serpentinites along shear zones. Magnesite is also confined to these zones, where it forms concretionary metasomatic lenses and fills irregular fracture cavities.

Production work was carried out in deposits 5-10 feet wide and horizontally extending to a depth of up to 500 feet. As with most other serpentinite-related deposits in California, the magnesite at Mount Red is cryptocrystalline, white and clear, conchoidally fractured, and resembles unglazed porcelain when freshly chipped. Bodenlos (1950) believes that magnesite was formed by the action of rising hydrothermal waters enriched in carbon dioxide, which changed the magnesian silicates of serpentinites into carbonate. The initial reserves of magnesite were estimated at approximately 1 million tons. By 1950, about 180 thousand tons were extracted, after which the deposit was not exploited.

Vitaliano (1951) described a magnesite occurrence in which magnesite occurred as nodules and lived in volcanic tuffs. The mineral composition and genesis of this deposit (Faust and Callaghan, 1948) are of considerable interest, but the magnesite reserves here are small and the deposit has not been developed.

Deposits of magnesite in the weathering crust of hypermafic rocks (Khalilovskoye in the Southern Urals), close to those in California, were also exploited. Magnesite, associated with metamorphosed dolomites, is of greatest industrial importance throughout the world; in addition to the largest deposits of this type in the Precambrian of China and Korea, this also includes the main European deposits in the Paleozoic carbonate strata of the Pyrenees, Alps and Carpathians. By all main features, these deposits are a product

LITERATURE

Bain G. W. (1924). Types of magnesite deposits and their origin, Econ. Geology, 19, 412–433.

Ball C. J. P. (1944). The Basic Magnesium enterprise, Amer. Inst. Min. Met. Eng. Trans.. 159, 285-292.

Bennett WAG (1941). Preliminary report on magnesite deposits of . Stevens County, Washington, Wash. Div. Geology Rept. Inv., 5.

Bennett WAG (1943). Character and tonnage of the Turk magnesite deposit, Wash. Div. Geology Rept. Inv., 7.

Bodenlos A. J. (1950). Geology of the Red Mountain magnesite district, Santa Clara and Stanislaus counties, California, Calif. Jour. Mines and Geology, 46, 223–278.

Bray W. T., Hilchey G. R. (1957). Magnesite deposits of Kilmar, Quebec, Geology of Canadian Industrial Mineral Deposits, Montreal, Can. Inst. Min. and Met., 164-166.

Callaghan E. (1933). Brucite deposit. Paradise Range, Nevada, Univ. Nev. Bull., 27, 1-34.

Campbell I., Loofbourow JS, Jr. (1946). Geology of the magnesite belt of Stevens County, Washington, Bull. Geol. Soc. Amer., 57, 1250.

Campbell I., Loofbourow JS, Jr. (1957). Preliminary geologic map and sections of the magnesite belt, Stevens County, Washington, US Geol. Survey Map MF 117.

Chelf C. (1941). Magnesite mining In Llano County, Texas, Tex. Bur. Econ. Geology, Min. Res. Survey Circ., 40.

Davis R. E. (1957). Magnesium resources of the United States—a geological summary and annotated bibliography to 1953, US Geol. Survey Bull., 1019-E.

Faust G. T., Callaghan E. (1948). Mineralogy and petrology of the Currant Creek magnesite deposits and associated rocks of Nevada, Bull. Geol. Soc. Amer., 59, 11-74; 1958, 69, 353-354.

Holmes G. H., Jr. (1949). Mining methods at the brucite deposit, Basic Refractories, Inc., Gabbs, Nye County, Nev., US Bur. Mines Inf. Circ., 7543.

Holmes G. H., Jr., Matson E. J. (1950). Investigation of the magnesite deposit of the Ala-Mar Magnesium Co., Inc., and Nevada Magnesite Co., White Pine County, Nev., US Bur. Mines Rept. Inv., 4608.

Martin C. (1956). Structure and dolomitization in crystalline magnesite deposits, Paradise Range, Nye County, Nevada, Bull. Geol. Soc. Amer., 67, 1774.

Martin C., W II lard HP (1957). Quality control in selective mining of magnesite. Min. Eng., 9, 425–427.

Nishihara H. (1956). Origin of the bedded magnesite deposits of Manchuria, Econ. Geology, 51, 698–711.

Perry J. W., Kirwan G. M. (1938). The Bald Eagle magnesite mine, California, America. Inst. Min. Met. Eng. Trans., 148, 35-50.

Rubey W. W., Callaghan E. (1936). Magnesite and brucite, in Hewett DF et al., Mineral resources of the region around Boulder Dam, US Geol. Survey Bull., 871, 113-144.

Schroeder MC (1949). The genesis of the Turk magnesite deposit of Stevens County, Washington, Compass, 26, 37-46.

Sea ton MY (1942). Production and properties of the commercial magnesias, Amer. Inst. Min. Met. Eng. Trans., 148, 11^31.

Ver Planck WE (1957). Magnesium and magnesium compounds, Calif. Div. Mines Bull., 176, 313-323.

Vital iano CJ (I960). Needles magnesite deposit, San Barnardino County, California, Calif. Jour. Mines and Geology, 46, 357–372.

Vitaliano C. J. (1951). Magnesium-mineral resources of the Current Creek district, Nevada, US Geol. Survey Bull., 978-A.

Vitaliano C. J., Callaghan E. (1956). Geologic map of the Gabbs magnesite and brucite deposits, Nye County, Nevada, US Geol. Survey Map MF 35.

Vitaliano C. J., Callaghan E., S i 1 ber 1 in g N. J. (1957). Geology of Gabbs and vicinity, Nye County, Nevada, US Geol. Survey Map MF 52.

Magic properties

Most stones used in the form of jewelry are endowed with magical qualities by people. These properties are also attributed to magnesite. It is believed that wearing an amulet made from this stone:

- It will boost your immunity and protect you from epidemics.

- Calms your nerves.

- Improves vision.

- Will teach the owner to communicate with animals, train them, and understand their language.

- Makes children calm and obedient.

- Will help you find a life partner.

- Improves relationships with relatives.

- Builds relationships in the work team (put a pyramid, prism or cube on the desktop).

- Will protect you from accidents and natural disasters on the way.

- Will open the abilities of clairvoyance and clairvoyance.

- Will reveal the talents of creative people, especially artists.

Application in construction

Magnesia binders contain caustic magnesite or caustic dolomite. In the ground state, they are mixed not with water, with which they harden very slowly, but with a solution of magnesium chloride (MgCl2), magnesium sulfate (MgSO4) or some other salts.

Magnesium binders harden in air, so they can only be used where it is dry. They are distinguished by the fact that they firmly adhere to fibrous materials, such as wood, so they are used in combination with shavings to produce thermal insulation material - fiberboard, and with sawdust to produce xylolite. The raw material for the production of caustic magnesite is the magnesite rock, consisting mainly of magnesium carbonate MgCO3. Pure magnesite is much less common than limestone and gypsum.

The production of caustic magnesite consists of two successive processes of firing and grinding.

Magnesite is fired in shaft, rotary and other kilns. The purpose of firing is to remove carbon dioxide from magnesite. Experiments have established that caustic magnesite of the best quality (as a binder) is obtained at a firing temperature of 800-850°.

Grinding of caustic magnesite is most often done in ball mills with air separators to separate fine particles. It is transported in iron drums with a capacity of 150 kg or in bulk in covered wagons, stored indoors, avoiding moisture and contamination.

Caustic magnesite is a fine white or yellowish powder.

Its specific gravity is 3.1–3.4%, i.e., more than ordinary Portland cement.

The magnesium oxide content in it must be at least 83% for the 2nd grade and 75% for the 3rd grade.

The most common binder for magnesium cement is a solution of magnesium chloride MgCl2 6H2O, which is a colorless or slightly yellowish transparent salt.

Medicinal properties

Magnesium carbonate is included in a number of medications that help with exacerbations of diseases of the gastrointestinal tract: gastritis, stomach and duodenal ulcers, constipation.

Pure magnesium is obtained from the mineral, which is used to create vitamins containing this trace element.

Natural magnesite stones are used for massage for arthrosis, arthritis, radiculitis, and other diseases of the musculoskeletal system.

Athletes rub powdered magnesia (a mixture of magnesium carbonate and bicarbonate) on equipment in gymnastics and weightlifting to avoid injuries and falls.

Chemical composition of magnesium binder

Caustic magnesite (MgO) or dolomite (MgO • CaCO3) give strength values of 400-600 kg/cm2 in compression (rammed samples), harden quickly (every other day - 35-50%, after 7 days - 60-90% of the monthly strength) , adhere well to wood, asbestos and other fibers. Magnolite products with sawdust are called xylolite, with shavings or wood wool - fibrolite, with asbestos - asbolite.

The normal ratio between binder and sealer (caustic magnesite, fused magnesium chloride) is 1: 0.62. When mixing with magnesium chloride, the strength of products is higher than with sulfate, but at the same time their hygroscopicity increases.

Caustic magnesite powder must have a specific gravity of 3.1-3.4 and contain magnesium oxide (MgO) in a percentage of at least:

- first class - 87

- second class -83

- third class -75

The grinding fineness must correspond to a passage through a sieve of 4900 holes/cm of at least 75%. The setting time for powder mixed with a solution of magnesium chloride (specific gravity 1.2) should be within the following limits: start no earlier than 20 minutes, end no later than 6 hours. Tensile strength after 1 day is not less than 15 kg/cm2.

Caustic dolomite powder has a specific gravity of 2.8–2.85; contains magnesium oxide (MgO) of at least 20%. The fineness of grinding must correspond to the passage through a sieve of 4900 holes/cm2 of at least 75%. Setting time: start no earlier than 2 hours, end no later than 12 hours. Tensile strength (mortar without filler) after 7 days—10—15 kg/cm2.

Technical magnesium chloride must contain at least 45% anhydrous salt MgCl2. The content of harmful impurities - calcium chloride (increases hygroscopicity, causes variability in volume and reduces strength), potassium and sodium chloride (reduces strength and causes efflorescence) - should not exceed a total of 2.5%.

Technical magnesium sulfate contains 44-46% pure MgSO4. Magnesia binders are used for seamless xylolite floors and tiles, fiberboard, artificial marble, steps, window sill boards, and architectural details.

Magnesite colors

For jewelry, talismans and amulets, matte and transparent crystals of white, yellow, pink, green colors with a glass sheen are used.

Yellow stones are mined in deposits in Australia, pink ones with opal particles are mined in France, large stones of a beautiful brown hue are mined in Brazil.

How to wear rings with natural stones correctly (video)

In addition, the mineral is in demand in the chemical, pulp and paper, pharmaceutical industries, in the production of electrical insulators, fire-resistant paints, artificial marble, plastics and rubber.

In the jewelry industry, the mineral is used very rarely for the most part, with the exception of bright yellow stones mined mainly in Brazil and Central Australia. Unscrupulous jewelers use colored magnesites as turquoise, lapis lazuli and red coral, significantly increasing the cost of fakes. The mineral is a very popular ornamental and collectible stone; most connoisseurs of natural gems are willing to sacrifice a lot in order to get themselves a large collectible specimen of magnesite measuring more than 100 carats.

Compatibility with zodiac signs

In astrology, it is believed that the magnesite stone protects the zodiac sign of Gemini. It protects against spontaneous decisions and losses, helps to tame excess excitement, and attracts good luck in games and business.

It helps Virgos and Capricorns to hear the voice of the heart, activate the work of the brain, and enable luck in career and business.

Important information

This mineral is contraindicated for Aries and Aquarius: it will lead them to depression with loss of interest in surrounding events or a nervous breakdown.

For other signs this stone is neutral. They can use it based on its magical properties.

Gallery: magnesite stone (35 photos)

The magnesite mineral has several medicinal properties : it has a calming effect on the nervous system and improves mood. It is able to relieve tension and any fears, and bring a person out of a depressive state. The white mineral will help relieve eye fatigue if you look at it for a while without blinking. The stone has a good effect on children, it makes them obedient, cheerful and friendly. As a talisman, the gem is well suited for sailors, drivers and travelers; it will protect them from dangers that may occur along the way.

In astrology, magnesites are considered ideal stones for Geminis; they restrain their excitement and protect them from financial losses.

The mineral will help Capricorns and Libra get the maximum benefit from any situation, and it will also help them advance in their careers. But such a talisman is contraindicated for Aquarius and Aries, since the energy of the stone can make them vulnerable to outside influence.

Application of the mineral

The use of magnesite has found its place in almost all industries. In the field of manufacturing building materials, the mineral is used to produce magnesite slabs, which, due to the basic properties of the rock, are very popular and in great demand.

They are environmentally friendly, fireproof, durable, not affected by moisture, have good sound insulation and are easy to process. They are actively used in finishing houses, garages, interior walls of saunas and swimming pools, and are used in the production of doors and the construction of floor coverings. The mineral purifies water well, neutralizes and removes heavy metals from it, which is why it is widely used in the manufacture of water purification filters. In the metallurgical industry, magnesites are used in the production of refractory bricks and cement.