In the modern gold mining industry, two methods of obtaining precious metals are actively used. The first method is called hydraulic; it consists of washing gold out of the rock under the influence of a stream of water supplied under high pressure. However, the second method, based on the use of a special machine, is much more effective.

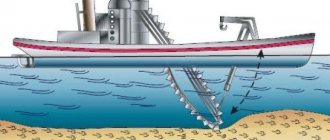

A dredge for gold mining is a huge device the size of a 4-story building and a weight that reaches 1,400 tons. The unit operates afloat, its design includes a whole complex of scoops that lift rock from the bottom of the reservoir, and from this rock by washing get gold ore.

The wide functionality of the dredge allows you to perform the entire range of tasks for the development of placer deposits, starting with the extraction of rock and its delivery to the washing site and ending with waste disposal.

To operate this colossus, the simultaneous efforts of 9 people are required, but the productivity of the device is simply amazing, it is equal to the efforts of 12 thousand miners, “armed” with primitive trays.

Types of dredges for gold mining and principles of their operation

The units that became the topic of our conversation come in two types: continental and marine. The design of both types is almost the same: a floating vessel, masts, equipment for scooping rock, a device for maneuvers, equipment for enrichment. The main difference lies perhaps in the absence of stalkers and piles in marine dredge models.

Continental dredge models are used to study and develop deposits on the mainland adjacent to a body of water. Such devices are based on pontoons. Marine models are used for gold mining, as well as for the extraction of all kinds of minerals and diamonds. Similar equipment is installed on ships, not only on towed ones, but also on self-propelled ones.

Important

Mini-dredges for gold mining have become very popular today.

In appearance, the device resembles a vacuum cleaner that sucks up sand mixed with ore and then separates it. The weight of such equipment varies from 24 to 90 kg, design features may be different, the following components and assemblies are the same:

- system providing buoyancy;

- a motor that drives a centrifugal pump;

- a chute designed for washing and separating rock;

- injector;

- air supply system (only on some models).

Speaking about the principle of operation of a dredge for gold mining, it is necessary to mention the following: a stream of water under enormous pressure is supplied to the injector. Rock (pebbles, sand, etc.) is drawn into it along with water and directed to the grid of the rinsing chute. The motor drives a pump that helps sift the gold from sand and debris.

Classification of dredges

Dredges are grouped:

- by the type of energy required for the operation of the device: electricity, energy from the combustion of gasoline or diesel fuel vapors;

- by depth of work with rocks below the water level: shallow-water, deep-water;

- by bucket capacity: small, medium, large;

- by maneuvering method: rope-pile, rope-anchor.

As a rule, two types of special machines are used for gold mining:

- marine;

- continental.

These types of dredges differ in that the marine special vehicle is similar to a ship that can be moved along the coast, while the continental one requires more resources, as it is mounted on a pontoon.

Smaller special vehicles called mini-dredges are ideal for individual gold miners or prospectors. They can either be purchased in special stores or made independently. The mini-drag has been significantly reduced in size. Its weight ranges from 25 to 100 kg.

A positive feature of using mini-dredges is that they reduce labor costs and speed up the gold mining process. Therefore, the interest of miners in constructing the unit with their own hands at home is justified.

How to pan or mine gold using a dredge

Before using a dredge for gold mining on rivers, a company or enterprise must collect a whole package of documentation and take care of obtaining the appropriate license. In this case, management must comply with a number of requirements:

- first of all - to conduct geological exploration;

- perform an analysis of the quality of the material, perform detailed calculations;

- prepare detailed designs for the development of future fields;

- take care of obtaining an allotment (land and/or mining).

If we are talking about using, for example, a mini-dredge on a private basis, it should be remembered that such activity is illegal and is prosecuted in accordance with the current regulatory framework.

True, this is not an obstacle for many of our compatriots - such a complex, full of adventurism, but, nevertheless, very profitable in some cases, the fishery enjoys considerable popularity in some regions of our state.

Methods of gold mining in Russia

Over time, gold mining methods have constantly improved and changed. At first, manual gold mining was widely used by sifting sand in water.

Then people mastered the extraction of noble metal from ore. These days, manual gold mining is a rarity. This process is mostly automated, but that doesn’t make it any easier. After all, to find a profitable deposit you need to spend a lot of effort and money. A payable deposit is considered to be one in which there are 3 grams of pure gold per 1 ton of soil.

More recently, in the gold mining industry, a method called amalgamation has been popular. Its peculiarity is the use of mercury placed at the bottom of the container. The barrel was filled with gold-bearing ore and shaken. As a result, gold particles remained in the mercury at the bottom of the barrel. The main negative quality of this method is the high toxicity of mercury.

Nowadays, gold is separated from ore using sodium cyanide. Thanks to the advent of this method, it became possible to extract gold from previously abandoned deposits, which returns their profitability.

Gold is also mined using dredges - surface-mounted mining machines equipped with everything necessary to extract metal from the ground. Dredging only works in areas with certain soil. This must be a watery area, so such special vehicles are often installed near river banks or other bodies of water.

How to mine gold sand by dredging

The process of washing sand with a dredge:

- The soil, which potentially contains particles of precious metal, is placed in the receiving hole.

- The installation washes the soil, removing excess fractions from it. The latest models of profile equipment are equipped with an automatic flushing function for coarse rock, which eliminates the risk of damage to the device.

- The washed soil is fed into a drum, where it is wetted and crushed into smaller parts.

- The next stage is that the soil is sent to the enrichment sluice, and then the remaining raw materials, which are guaranteed to contain nothing valuable, are thrown back.

The functionality of the dredge for sand extraction provides the ability to make individual settings, in particular:

- intensity of rock cleaning;

- fuel consumption;

- drum rotation speed;

- cleaning method (depending on soil type).

Gold extraction in jigging machines

Enrichment by jigging is based on the separation of mineral grains by density in water, oscillating (pulsating) relative to the separated grains in a vertical plane. The pulsation of the medium is created by a special drive mechanism.

Crushed ore in the form of pulp is fed to the sieve of 1 jigger. When enriching fine material, a layer of artificial bed 2 made of another material is first laid on the sieve. The density of the artificial bed material should be less than the density of the heavy mineral of the mixture being separated and greater than the density of the light one.

When beneficiating gold ores, metal shot or hematite ore is usually used as a bed. The particle size of the bed is taken to be 3–6 times larger than the maximum particle size of the enriched material. The pulp of the source material moves along the bed along the sieve.

Under the influence of gravity, solid particles tend to settle on the bed, but their settling rates are different. For heavy particles it is greater than for light particles. With an upward flow of water, gold particles lag behind light particles of waste rock as they move upward with water.

With a downward flow, gold particles have time to move towards the sieve, ahead of light particles.

When the water pulsations created by diaphragm 3 are repeated, the material is stratified by density: particles of gold and other heavy minerals fall through the bed and are unloaded under the sieve, light grains of waste rock remain on the surface of the bed and are unloaded through the drain threshold. Water enters the jigging machine with the processed material; in addition, a certain amount of water is additionally introduced under the sieve.

The main technological parameters of the jigging machine that affect the extraction of gold and the quality of the resulting concentrate are the characteristics of the artificial bed, the frequency and range of pulsations, the speed of the upward flow of under-grid water, the productivity of the machine, and dilution of the feed.

Advice

Fluctuations (pulsations) of water in jigging machines are created in various ways. The most widely used are jigging machines in which water vibrations are created by swinging a horizontal (bottom) or vertical diaphragm.

Domestic factories widely use two-, three- and four-chamber jigging machines of the MOD type. The structure of the three-chamber jigging machine MOD-ZM is shown in the figure below. Housing 1, welded from sheet steel, has the shape of a rectangular box, divided into chambers by vertical transverse partitions.

Each chamber has a 4 sieve on which the bed is laid. To evenly distribute the bed, an additional coarse sieve 3 is installed above the sieve. Each chamber of the body in the lower part goes into a funnel, to which a conical bottom 6 is attached through a rubber diaphragm 8.

Due to a special mechanism (7, 10, 11, 12), the conical bottoms have a reciprocating movement in the vertical plane. The number of swings is 130 – 380 per minute, the swing range is no more than 40 mm. The source material is fed through the loading chute 2 and sequentially passes through the sieves of all chambers.

The light fraction (tailings) is unloaded through the drain threshold 5, and the heavy fraction through unloading devices 9 in the bottoms.

Diaphragm jigging machine with horizontal diaphragm MOD-3M

In recent years, jigging machines, characterized by higher unit productivity, and air-pulsation machines have been introduced.

Jigging machines are widely used to capture free gold in the grinding cycle. When grinding gold ores, mills, as a rule, operate in a closed cycle with a classifier.

The gold particles exposed during grinding are not crushed themselves, since gold is a malleable metal. Therefore, large heavy particles of free gold will accumulate in the circulating load (classifier-mill).

note

To remove free gold at the unloading of the mill, jigging machines are installed in front of the classifier.

The main advantages of jigging machines are the ability to process unclassified material, high productivity per unit surface, and the ability to work on pulps with a low liquid-solid value.

Jigging machines installed in the grinding cycle of gold ores usually provide rough concentrate with a yield of tenths to several percent and extraction of free gold up to 20 - 40% or more, depending on the size of gold in the original ore.

Dredge cost: current offers

We analyzed the proposals on thematic Internet resources and came to the conclusion that the cost of industrial installations is negotiated on an individual basis.

Important

On the website of manufacturers of such equipment, after a detailed description of the models available for purchase, there is a message that to clarify the price you need to contact the seller.

For example, one of the sites we studied presents a wide range of Julong industrial dredges. The seller offers consumers a wide variety of models - amphibious self-propelled crawlers, mine, bucket, jet suction dredges, portable and stationary installations - the choice is huge, however, in the “Price” column, “Negotiable” is indicated everywhere.

As for options for private use, the situation here is as follows:

- Mini dredge Keene 4500 RN from a reputable American manufacturer, Engineering, costs 450 thousand rubles. The seller, according to the data presented on the website, is located in Krasnoyarsk.

- The Russian-made mini-drag “Nugget-50” costs 139,400 rubles and is sold in the city of Bratsk. A less powerful model from the same manufacturer, “Nugget-40,” costs much less – 75 thousand rubles. All the models we mentioned, according to the seller, are new and are covered by a factory warranty.