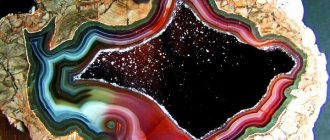

Carborundum (silicon carbide) is a dense material of varying degrees of transparency, obtained by combining sand with coal by melting. Black specimens resemble anthracite in appearance, but there are other shades. In bright light, the mineral shimmers with rainbow colors, forming various patterns on the surface.

Mineral – Carborundum

Due to its numerous beneficial properties, carborundum is used not only in the jewelry industry, but also in electronics, steelmaking, etc. In addition, the mineral has magical and healing effects.

History and origin

They learned how to produce carborundum synthetically since the middle of the 19th century, but it was patented only in 1893. Until 2016, the USA was the manufacturer of artificial stone, but today China is recognized as its main supplier to the world market. Currently, about 250 modifications of carborundum of different colors and shades are produced. Stones used in the jewelry industry are covered with a special film, which allows the crystal to look like a real diamond.

In nature, this crystal is distributed in very small quantities, so it is almost impossible to find large deposits.

Important! The process of producing factory stone takes place on the latest technological equipment, where specialists carefully control its growth stage. This allows you to obtain an almost perfect mineral (without possible flaws).

Production

Synthetic SiC crystals with a diameter of ~3 mm

Since natural moissanite is so scarce, most silicon carbide is synthetic. Silicon carbide is used as an abrasive, as well as a semiconductor and a gem-quality diamond simulant. The simplest method for producing silicon carbide is to combine quartz sand and carbon in an Acheson graphite electric resistance furnace at a high temperature of 1600 °C (2910 °F) to 2500 °C (4530 °F). Fine particles of SiO 2 in plant material (eg rice husks) can be converted to SiC by heating excess carbon from the organic material. Microsilica, which is a by-product of the production of silicon metal and ferrosilicon alloys, can also be converted to SiC by heating with graphite at 1,500 °C (2,730 °F).

The material produced in the Acheson furnace varies in purity depending on the distance to the graphite resistor heat source. Colorless, pale yellow and green crystals have the highest degree of purity and are closest to the resistor. The color changes to blue and black the further away from the resistor, and these darker crystals are less pure. Nitrogen and aluminum are common impurities and they affect the electrical conductivity of SiC.

Synthetic SiC Lely crystals

Pure silicon carbide can be produced by the Lely process, in which SiC powder is sublimated to the high temperature species silicon, carbon, silicon dicarbide (SiC2) and silicon carbide (Si2C) in an argon atmosphere at 2500 °C and reprecipitated into flake single crystals up to 2 × 2 cm in size on a slightly cooler substrate. The result is high-quality single crystals, mainly from the 6H-SiC phase (due to the high growth temperature).

A modified Lely process involving induction heating in graphite crucibles produces even larger single crystals, 4 inches (10 cm) in diameter, with a cross-section 81 times larger than the traditional Lely process.

Cubic SiC is usually grown using a more expensive chemical vapor deposition (CVD) process of silane, hydrogen and nitrogen. Homoepitaxial and heteroepitaxial SiC layers can be grown using both gas and liquid phases.

To form SiC with complex shapes, preceramic polymers can be used as precursors, which form the ceramic product by pyrolysis at temperatures in the range of 1000–1100 °C. Precursor materials for producing silicon carbide in this manner include polycarbosilanes, poly(methylsiline) and polysilazanes. Silicon carbide materials produced by pyrolysis of preceramic polymers are known as polymer-derived ceramics, or PDC. Pyrolysis of preceramic polymers is most often carried out in an inert atmosphere at relatively low temperatures. Compared to the CVD process, the pyrolysis method has the advantage that the polymer can be formed into various shapes before thermalization into ceramics.

SiC can also be made into wafers by cutting the single crystal with a diamond saw or laser. SiC is a useful semiconductor used in power electronics.

Physico-chemical properties of stone

Chemical formula: SiC

State: crystals, druses or crystalline powders from transparent white, yellow, green or dark blue to black, depending on purity, dispersity, allotropic and polytypic modifications.

Melting point: 2830°C

Silicon carbide

:

- Density 3.05 g/cm³

- Composition: 93% silicon carbide

- Ultimate bending strength 320…350 MPa

- Compressive strength 2300 MPa

- Elastic modulus 380 GPa

- Hardness 87…92 HRC

- Crack resistance within 3.5 - 4.5 MPa m1/2,

- Thermal conductivity coefficient at 100 °C, 140-200 W/(m K)

- Coeff. thermal expansion at 20-1000 °C, 3.5…4.0 K−1⋅10−6

- Fracture toughness 3.5 MPa m1/2

Also read: Selenite - the secret magical properties of the stone

Self-bonded silicon carbide

:

- Density 3.1 g/cm³

- Composition: 99% silicon carbide

- Ultimate bending strength 350-450 MPa

- Compressive strength 2500 MPa

- Elastic modulus 390–420 GPa

- Hardness 90…95 HRC

- Crack resistance within 4 - 5 MPa m1/2,

- Thermal conductivity coefficient at 100 °C, 80 - 130 W/(m K)

- Coeff. thermal expansion at 20-1000 °C, 2.8…4 K−1⋅10−6

- Fracture toughness 5 MPa m1/2

VK6OM

:

- Density 14.8 g/cm³

- Composition Tungsten carbide

- Ultimate bending strength 1700…1900 MPa

- Compressive strength 3500 MPa

- Elastic modulus 550 GPa

- Hardness 90 HRA

- Crack resistance within 8-25 MPa m1/2,

- Thermal conductivity coefficient at 100 °C, 75…85 W/(m K)

- Coeff. thermal expansion at 20-1000 °C, 4.5 K−1⋅10−6

- Fracture toughness 10…15 MPa m1/2

Siliconized graphite SG-T

:

- Density 2.6 g/cm³

- Composition: 50% silicon carbide

- Ultimate bending strength 90…110 MPa

- Ultimate compressive strength 300…320 MPa

- Elastic modulus 95 GPa

- Hardness 50…70 HRC

- Crack resistance within 2-3 MPa m1/2,

- Thermal conductivity coefficient at 10 °C, 100…115 W/(m K)

- Coeff. thermal expansion at 20-1000 °C, 4.6 K−1⋅10−6

- Fracture toughness 3…4 MPa m1/2

Engine capacity

Before talking about compression and compression ratio, let's understand the concept of volume. A cylinder has 3 types of volumes:

The total volume includes the working volume and the volume of the combustion chamber. Each engine has a certain number of cylinders. To find out the total engine volume, you need to add up the parameters of each cylinder.

Engine cylinder volumes

To calculate the working volume of one cylinder, you need to multiply the cross-sectional area of the cylinder by the length of the piston stroke. The piston stroke length is determined by the distance from bottom dead center (BDC) to top dead center (TDC), i.e. from the maximum lower to the maximum upper position of the piston.

According to the formula it looks like this: Vwork. = πr 2 h, where π = 3.14, r is the radius, h is the length of the piston working stroke.

For example, if the volume of one cylinder is 499 cubic centimeters, and there are four cylinders, then you need to multiply 499 by 4 and we get 1996 cubic centimeters. Next, round to 2000 and divide by 1000 to get the value in liters. Thus, the engine displacement will be 2 liters.

Engine volume is a parameter of the internal combustion engine that determines its power.

In most countries, the cost of car tax depends on the engine displacement. The higher it is, the more expensive the tax is. For example, the engine volume of the Japanese Kei Car is only 0.66 cubic centimeters. Owners of these cars do not pay road tax at all.

The displacement of any engine is measured in cubic centimeters or liters. Based on volume, cars are divided into categories:

- minicar (no more than 1.1 liters);

- small-capacity (from 1.2 to 1.7 liters);

- mid-displacement (from 1.8 to 3.5 liters);

- large-capacity (from 3.6 and more).

The larger the volume, the more fuel-air mixture is placed in each combustion chamber. This indicator directly affects fuel consumption, but at the same time the car’s power increases.

Areas of application

Carborundum is used in many areas of industry because it is highly resistant to destruction and extreme temperatures. Here are the main areas of its application:

- As a structural material, stone is used to make brakes for racing cars, panels and slabs, elements for military equipment, abrasive attachments, etc.

- In electronics, semiconductor devices (thyristors), ultra-fast diodes, etc. are made from silicon carbide.

- In steelmaking - it is used as fuel for the production of steel, as well as in the correction of temperature conditions in the production of metal products.

- In nuclear energy, the mineral is used to make a coating for nuclear fuel elements, added to grinding pastes, etc.

- In jewelry - it is used as moissanite (because it resembles a diamond in appearance), it is used to decorate rings, necklaces, chokers, bracelets, earrings, brooches, etc.

Also read: Sugilite - a mysterious gem from Iwagi Island

Interesting fact! Moissanite is often used to imitate a diamond, selling products to the buyer at the cost of an expensive gemstone (since it is difficult to distinguish one from the other with the naked eye).

What is carbide?

Homemade bombs. This is what comes to mind first when we hear the word carbide. And no, the production of these dangerous toys was not carried out by defense industry enterprises, but, as a rule, by boys, about ten years old.

Twenty years ago it was a favorite pastime among teenagers. Now everyone sits at their tablets, but back then the world was ruled by the inquisitive mind of a child who strove to try everything in practice.

In order to feel like Rimbaud, you needed to get one miracle stone. Children most often found them at construction sites. And then everything was simple: a plastic vessel, a stone, water, a tightly screwed cap. All this was zealously shaken, and at best, thrown away. And in the worst case, the “shell” exploded right in the hands, then injuries could not be avoided.

Calcium carbide

There were also safer ways to use the find, for example, simply throwing it into a puddle, then you could observe something similar to the effect of modern bath bombs. So what kind of popular “toy” is this? Most of us believed that nature produced carbide as we know it. But actually it is not. And today you will see this.

So, this substance is always very hard, plus, in order to melt it, you need to make a remarkable effort. They look like dark, light, greenish stones, or powder, it all depends on the composition. Its shelf life is short, usually six months. It will not be possible to place containers in a general warehouse; such potentially dangerous substances must have their own compartment.

As you already know, carbide constantly strives to explode. Moreover, some connections do not even need special conditions. It is enough just to pour the powder from container to container, and it can suddenly explode.

Medicinal properties

In addition to practical use in various industries, the mineral has medicinal properties. Here are some of them:

- Relieves phobias and prolonged depression.

- Calms nerves and improves sleep.

- Normalizes metabolism.

- Improves the condition of the gastrointestinal tract in case of gastritis or ulcers.

- Restores liver function, eliminating hepatitis and early stage cirrhosis.

- When worn continuously, it eliminates headaches and joint pain.

- Normalizes hormonal levels.

- Improves hematopoiesis, and is especially useful for anemia.

- Strengthens the immune system.

Links

- Kelly, Jim.

A brief history of SiC: [arch. 01/19/2008] // Jim Kelly's filing cabinet. - Department of Chemistry, University College London, 2005. - October 7. — Date of access: 06/23/2020. - Silicon carbide: technology, properties, application / Ed. Belyaeva A. E., Konakova R. V. - Kharkov: ISMA, 2010. - 532 p. — ISBN 978-966-02-5445-9

- Digonsky S.V.

Gas-phase processes of synthesis and sintering of refractory substances. - M.: GEOS, 2013. - 462 p.

| Dictionaries and encyclopedias |

|

| In bibliographic catalogs |

|

Magic properties

Carborundum has the following magical properties:

- Improves material well-being and attracts money to its owner.

- Helps overcome fear on the way to the goal, sweeping away all obstacles along the way.

- Helps its owner gain sexual attraction for the opposite sex.

- Improves memory and intellectual abilities.

- Protects from external negativity (damage, evil eye, curse).

Be careful! It is not recommended to carry carborundum with you at all times, as this can lead to nervous agitation or insomnia.

Stone cost

Carborundum has a relatively low cost, so everyone can afford it. Here are its approximate prices (measured in Russian rubles):

- Raw nuggets (crystals) - can be purchased within 1000 rubles.

- As jewelry (pendants, rings, necklaces, bracelets, etc.) - 4000-15000.

Stone earrings

Caring for your jewelry

The artificial mineral material is quite resistant to external damage, high temperatures and acids, so caring for it is easy and simple. In order for moissanite to serve “faithfully and truly” for a long time, it is enough to comply with 2 conditions:

- Store the stone in a box (you can “company” other jewelry).

- If necessary, clean with any detergents, with the exception of abrasives (since the microfilm applied to the surface of the stone may be damaged).

Compatibility with zodiac signs

(“+++” – the stone fits perfectly, “+” – can be worn, “-” – is strictly contraindicated):

| Zodiac sign | Compatibility |

| Aries | +++ |

| Taurus | + |

| Twins | +++ |

| Cancer | + |

| a lion | +++ |

| Virgo | + |

| Scales | +++ |

| Scorpion | + |

| Sagittarius | +++ |

| Capricorn | + |

| Aquarius | +++ |

| Fish | + |

The mineral suits all zodiac signs without exception. But it will bring the greatest benefit to people of the elements of Fire (Leo, Sagittarius, Aries) and Air (Aquarius, Gemini, Libra).

Is this stone right for you?

Interesting things about the stone

Several interesting facts about the stone have been circulated:

- Near the Vesuvius volcano (located in Italy), solidified lava is sold to tourists as carborundum.

- Moissanite is often called a “space” stone, because it is present in greater quantities in space than on Earth.

- Scientists suggest that natural silicon carbide first appeared outside the solar system. They came to these conclusions after studying the Murchison meteorite.

- The mineral was first discovered by the French scientist Henri Moissan. Hence its self-explanatory name.

Carborundum

Carborundum = synthetic moissanite - artificially obtained silicon carbide. Is not a mineral

Carborundum = synthetic moissanite - artificially obtained silicon carbide. It is not a mineral.

Obtained by fusing sand and coal (i.e. silica and carbon). It resembles anthracite, but shimmers with all the colors of the rainbow.

The refractive index of a jewelry sample of carborundum (2.65) is higher than that of diamond (2.42).

Carborundum was patented by Edward Goodrich Acheson on February 28, 1893, but there were reports of the preparation of this compound earlier, for example Despretz (1849), Marsden (1880) and Colson (1882).