Many people are interested in the slightly mysterious and not fully studied titanium - a metal whose properties are somewhat ambiguous. Metal is both the strongest and most fragile.

The strongest and most fragile metal

It was discovered by two scientists with a difference of 6 years - the Englishman W. Gregor and the German M. Klaproth. The name titan is associated, on the one hand, with the mythical titans, supernatural and fearless, and on the other hand, with Titania, the queen of fairies. This is one of the most common materials in nature, but the process of obtaining pure metal is particularly complex.

Production and manufacturing

Due to its prevalence in nature, mining ore containing titanium is not difficult. The most common types of ore that contain this metal are brookite, ilmenite, anatase and rutile. However, further processing of titanium (melting, hardening and aging) is considered expensive. There are several stages in obtaining pure metal from ore:

- First of all, titanium slag is extracted by heating ilmenite to 1650 degrees.

- Next, the slag goes through a chlorination process.

- After this, titanium sponge is produced using resistance furnaces.

- To obtain pure metal, the final processing step is the refining process.

If you need to obtain titanium ingots, a sponge based on it is melted in a vacuum furnace.

Magnesium-thermal process

Magnesium thermal reduction is a popular method for obtaining metal. Carrying out the technological process:

- The circulating magnesium condensate melts.

- The magnesium chloride condensate is drained.

- At a temperature of 800 degrees, liquid titanium tetrachloride with liquid magnesium is fed into a mold to solidify. Feed rate - 2.1–2.3 g/h cm2.

Gradually the temperature drops to 600 degrees.

Calcium hydride method

This is an industrial method of metal recovery. Work process:

- At a temperature of 500 degrees Celsius, calcium metal is saturated with hydrogen.

- Next, it is mixed with titanium dioxide. The components are heated in a retort, gradually increasing the temperature to 1100 degrees.

- The sintered components are washed out of the retort.

- Next, treatment is carried out with hydrochloric acid.

- Titanium powder is dried and baked in induction ovens at a temperature of about 1400 degrees.

The sintered mass should be subjected to a pressure of 10-3 mm.

Electrolysis method

A method for producing an alloy based on the use of electric current. Voltage affects TiO2, TiCl4. Before this, they are dissolved using molten fluoride salts.

Iodide method

Method for obtaining metal after thermal dissociation of TiJ4. Initially, it is obtained by reacting iodine vapor with titanium metal.

To obtain a high purity alloy, it is necessary to use the latter method of obtaining the compound. The first three methods allow you to quickly obtain technical titanium.

Being in nature

In nature, titanium is presented in the form of compounds with oxygen. Pure forms do not occur.

Under the influence of meteorological conditions, the structure approaches corundum (a compound of aluminum with oxygen). It is found in marine clay, in aluminum ores with iron and silicon.

Titanium is presented in minerals: titanite, titanomagnetite, rutile. Australian, Brazilian, and Canadian deposits of the latter are known. The mineral is presented in the form of bucrite and anatase.

A widely encountered mineral is iron titanate (ilmenite). Large deposits are represented in Russia and North America.

Advantages and disadvantages

Like any other metal, titanium has its strengths and weaknesses. Benefits include:

- light weight;

- corrosion resistance;

- resistance to high temperatures;

- high strength - greater than that of the best steels.

Flaws:

- Dust and chips remaining after processing titanium workpieces can ignite at a temperature of 400 degrees.

- This metal is difficult to weld and is practically impossible to cut.

- The costly method of obtaining metal from ore causes its high cost.

However, despite the existing disadvantages, the material and its alloys are widely used in various industries.

Light weight

Myths about Titan

Several myths about titanium

I answer the most common misconceptions regarding titanium and products made from it.

1. Titanium is the most durable and hardest material. Nothing like that, the most durable and hardest material in the world is diamond. Common hard materials include very hard tungsten carbide and many tungsten-molybdenum-containing alloys. These are cold and heavy materials that are practically not amenable to machining by turning and milling, and even more complex and modern processing technologies are used for them. In fact, the vast majority of the toughest metal-cutting tools are made from some combination of tungsten and other hard elements, including tools for machining titanium. Tungsten-containing alloys are classified as hard alloy materials. They are practically not used for making jewelry, only occasionally, because... the manufacture of complex products from tungsten-containing materials requires too huge production capacities, justified only in mechanical engineering and metal production, where such jewelry is considered a not-so-cool bonus to the main activity. Below is a diagram for measuring hardness using a hardness tester, in various units.

2. Titanium does not scratch. It scratches, and how. True, the differences in the scratchiness of the brands are quite pronounced and noticeable even with the naked eye. This parameter is influenced by the chemical composition of the alloy and the type of post-processing of the workpiece. Titaniums of top brands, products from which last in all their glory for a long time, are expensive and extremely difficult to get. And cheap brands are on sale at any metal warehouse and cost a penny, but the products made from them are cheap, but will not shine with quality. However, it is worth noting that precious metals scratch at least twice as hard as the cheapest grade of titanium. Some types of titanium alloy are easy to scratch, some are more difficult, and some are even more difficult. In any case, those who claim that titanium does not scratch are lying. However, to improve surface hardness, special coatings can be applied to products, which will significantly increase wear resistance. A picture of the “scratched surface” is attached.

3. Titanium is absolutely biocompatible. Almost true. However, only almost. There are several bio-incompatible (more precisely, allergenic) brands that contain harmful impurities (but these brands are quite rare and it is unlikely that the master will come across them, but who the hell is not kidding), also similar impurities that cause allergies, necrosis, or at least unpleasant sensations can can also be found in cheap brands due to low quality control of the composition in production (“Why, one might ask, check these samples for biocompatibility, bother with perfect cleaning, when we are going to make a housing out of them for the space station thermostat, which will also be located outside the ship?"). Therefore, before making jewelry and costume jewelry, a decent master jeweler will always take a sample of the material for chemical analysis, and only then offer it to the client. Below is a beautiful picture of a dental implant.

4. Titanium products should be cheap, because titanium is a very cheap material. The most common misconception! Titanium, compared to precious metals, is, of course, inexpensive, however:

a) There are very big problems in purchasing good brands in small quantities, because... such titanium is sold only in large industrial quantities, or even not sold at all - God grant that you can buy some scrap from the leftovers “from the master’s table” of the space and military industry, maybe you’ll get lucky. The most expensive titanium in the world costs about $1,500 per kilogram, the cheapest - about 1,500 rubles per kilogram (as of 2019)

b) The largest part of the cost of products is the processing of titanium, since it requires a unique, expensive tool and a large amount of time, and time is a non-renewable resource. Moreover, the better the titanium, the more expensive the tool and the more time it takes to manufacture, subject to the manufacturing technology of the products. In order to do it efficiently, in compliance with all tolerances and parameters, the technology cannot be violated, otherwise there will be defects and wasted material. After all, you can do it well, and then the product will not be cheap, but it can be done haphazardly, without claims to accuracy, or just to create the illusion of quality. And setting stones in titanium is a separate article for a master’s hemorrhoids. As it turned out, different brands of titanium require a different approach to setting various inserts, everything is not so simple with it - it is capricious, springy, and requires not exactly a jewelry (but cooler) and expensive tool for insertion and fastening. Below is a video of the exciting operation of a five-axis turning and milling machine - this is one of the top metal processing technologies, including titanium. The use of such technologies for the manufacture of jewelry cannot be cheap. Look.

Remember, in production there are three magic words, three components that allow you to combine each other in different positions, but always, always one of the words will be superfluous. It is “fast”, “high quality” and “inexpensive”.

5. Pure titanium is best. It depends on what purposes and objectives. Relatively pure titanium of the Russian and foreign registries is cheap, but has strength and hardness slightly higher than gold and silver, and a low level of these parameters will scratch a perfectly formed surface during the first day of use. If strong claims are made regarding the purity of the material, then there are iodide and refined titaniums, but you will not be happy with the price of them. Well, the most common, relatively pure and “simple” titanium is used mainly to reduce the cost of jewelry products that do not pretend to have surface quality, when creating very complex geometric shapes, or in the case of using it in casting technology or some other, not very expensive processing technology.

Regarding the advantages and uniqueness of titanium alloys, it is worth clearly noting their resistance to corrosion (some are more, some are less, but titanium, as a rule, does not corrode in non-violent environments), with their lightness, high strength, relatively high, and sometimes very high hardness and almost absolute biocompatibility (see above). Titanium does not darken, does not tarnish over time, does not oxidize in aggressive cleaning chemicals, and well-made products from high-quality titanium look great, some of them really do not scratch well and serve for a long time with their excellent appearance.

Characteristics and properties

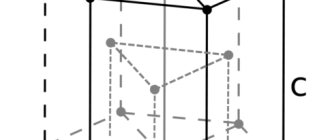

The characteristics of titanium directly depend on the amount of impurities contained in its composition. Physical parameters:

- Specific strength - 450 MPa.

- The melting point of titanium is 1668 degrees.

- Boiling point - 3227 degrees.

- The tensile strength of the alloys is 2000 MPa.

- The elasticity of titanium is 110.25 GPa.

- Metal hardness - 103 HB.

- The yield strength is 380 MPa.

The structure and properties of this metal determine its low electrical conductivity. Under normal conditions, titanium has a high resistance to corrosion processes.

Metal

Physical properties of metal

Titanium is a silvery-white metal. It is refractory, slightly heavier than aluminum. However, with slightly more weight, titanium has three times the strength. Amenable to various processing methods. Resistant to moisture and acids. The main properties of titanium have been described above.

Chemical properties of titanium

Under normal conditions, an oxide film forms on the surface of this metal, which protects it from the destructive effects of moisture and acids. The chemical properties of titanium include its resistance to alkalis and chlorine solutions. Has an oxidation state of +4. It begins to interact with oxygen at a temperature of 600 degrees. Titanium filings may spontaneously ignite when heated.

Large deposits

China occupies the leading position, followed by the Russian Federation and North America (Canada). The largest deposit where titanium is mined in the Russian Federation is located on the territory of the Komi Republic and is called the Yaregskoye oil field.

The top ten countries for titanium mining include:

- USA;

- India;

- Australia;

- SOUTH AFRICA;

- Sweden;

- Norway;

- South Korea.

Types of alloys

Titanium alloys can be divided into three large groups:

- Compounds based on chemical compounds. Representatives of this group have a heat-resistant structure and low density. A decrease in density directly affects a decrease in the weight of the material. Such alloys are used in the manufacture of parts for cars, frames for aircraft and hulls for ships.

- Heat-resistant alloys with low density. This is an analogue of compounds with nickel, but at a lower price. Depending on the chemical composition, the resistance of the titanium alloy to high temperatures varies.

- Structural - high-strength connections that are easy to process due to their high ductility. These alloys are used to make parts that are installed in equipment that operates under heavy loads.

When producing titanium alloys, official markings are used that indicate what metals it is combined with.

[edit] Distribution

The average titanium content in the earth's crust (clarke) is 0.45% (according to other data - 0.61% to a depth of 16 km). Only three other important metals—aluminum, iron, and magnesium—are more abundant in nature than titanium. The pegmatites of granites and alkaline rocks are richest in titanium.

By the beginning of the 21st century. About 100 titanium minerals are known. Titanium is included as an impurity in a number of minerals.

The main minerals of titanium ores: ilmenite (43.7-52.8% TiO 2); rutile, anatase and brookite (94.2-99.5); leucoxene (61.9-97.6); loparit (38.3-41); sphene (33.7-40.8); perovskite (38.7-57.8).

The amount of titanium in the earth's crust is several times greater than the reserves of copper, zinc, lead, gold, silver, platinum, chromium, tungsten, mercury, molybdenum, bismuth, antimony, nickel and tin combined. The titanium clarke in basic igneous rocks is 20.46 atomic %.

Properties and applications of titanium alloys

Titanium alloys do not have the main disadvantages of pure metal. When adding third-party materials, its characteristics change. Key properties of titanium alloys:

- resistance to corrosion processes;

- low density;

- high specific strength.

Alloys are also more resistant to high temperatures. Thanks to increased protection against acids and alkalis, alloys based on this material have gained popularity in the chemical industry and medicine. They are used in construction, production of equipment, cars, airplanes, rockets and ships.

Titanium and compounds based on it are common in various industries. This metal has unique characteristics that set it apart from other materials. Due to the difficulties of obtaining pure metal, its price is quite high.

History of discovery

The appearance of a new element is associated with the names of Gregor and Klaproth. Both singled it out almost simultaneously in 1791 and 1795. respectively.

Martin Heinrich Klaproth

In 1805, it was isolated again by Vauquelin from anatase. Moreover, pure titanium was obtained in Holland more than a century after its isolation.

Biocompatibility

Even in its natural form, titanium is biocompatible with almost all types of human skin. This means that almost anyone can wear titanium jewelry without fear of rashes and other allergic reactions of the body. Often, even those people who are intolerant to gold or silver products can wear titanium without any problems.

The main reason is that, unlike other precious metals, titanium is not mixed with other alloys and metals that can cause allergies. Titanium exhibits its best qualities in its “pure form”, so it is suitable for almost every person.

Photo

Titanium is often called the eternal metal. The choice of paired titanium rings symbolizes the eternity of your love, your union and the eternal unity of male and female.

[edit] Literature

- Glossary of terms in chemistry // J. Opeida, O. Shvaika. Institute of Physical-Organic Chemistry and Coal Chemistry named after. L. N. Litvinenko NAS of Ukraine, Donetsk National University - Donetsk: "Weber", 2008. - 758 p. ISBN 978-966-335-206-0

- Mountain encyclopedic dictionary: in 3 volumes / Ed. V. S. Beletsky. — Donetsk: Eastern Publishing House, 2001-2004

Electrochemical activity series of metals

, , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , H2

, , , , , , , , , , , , , , , , ,

| Periodic table of chemical elements by D. I. Mendeleev | |||||||||||||||||||||||||||||||||||||||||||

| Ti | |||||||||||||||||||||||||||||||||||||||||||

| Uue | Ubn | Ubu | Ubb | Ubt | Ubq | UBP | Ubh | ||||||||||||||||||||||||||||||||||||

| Alkali metals | Alkaline earth metals | Lanthanides | Actinoids | Superactinoids | Transition metals | Other metals | Semimetals | Other non-metals | Halogens | Noble gases | Properties unknown | ||||||||||||||||||||||||||||||||