How jewelry production works in Russia: SUNLIGHT case

23 March 2021, 12:25

How jewelry production works in Russia: SUNLIGHT case

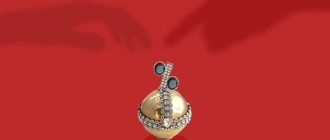

Jewelry production in Russia is unique - it combines both modern technologies and the traditions of Russian craftsmen. We can say that jewelry production is the metallurgical and metalworking industry in miniature. It is distinguished from other industries by its susceptibility to seasonality and constant changes in fashion trends, which necessitates the need to constantly quickly and often radically diversify the assortment and, accordingly, the technological routes for manufacturing products. Typically, the production department employs more than 300 people: from engineers, machine operators and technologists to artists and fashion designers.

Jewelry production of Russia's largest jewelry hypermarket SUNLIGHT is concentrated at factories in Kostroma, Moscow, St. Petersburg, Novosibirsk, Yekaterinburg, Krasnoyarsk and Izhevsk. The company also cooperates with local jewelry suppliers who already have their own production. Suppliers are selected based on the quality of jewelry products, proposed prices for the manufacture of certain jewelry products, production capacity and working conditions.

The main materials used in the production of jewelry - gold and silver - are purchased by the company from large refineries and banks at international exchange prices. Precious and semi-precious stones for production are purchased from global stone suppliers.

Nina Sergeeva, purchasing director of a jewelry hypermarket

, says that when selecting and purchasing materials, attention is first paid to the price-quality ratio, as well as working conditions.

“It is also worth mentioning that the price of diamonds consists of four parameters, the so-called “4Cs”: cut, clarity, color, carat -

this is cut, color, clarity and weight. The last factor plays an important role in determining the price of a diamond, because the larger it is, the higher its value. When purchasing, the company's team of professionals mainly pays attention to the third category of diamond color, less often to the fourth - these are those same colorless diamonds with a subtle tint. Most often in the assortment you can find diamonds of the 5th and 6th clarity groups, where there are subtle inclusions that can only be recognized with a magnifying glass.”

In the process of a full production cycle, a jewelry product goes through a path consisting of the following stages

: preparation of the project, creation of a sketch and drawing, casting of a model and model, creation of the first sample and presentation of the model, assignment of a series, testing of the product in the Assay Chamber of Russia, packaging, delivery to the customer’s warehouse, distribution to retail outlets, sale. The actual production of a product can be divided into five stages: procurement, semi-finished product, finishing, application of protective coatings and packaging. At each stage, there is a mandatory agreement with the working group, consisting of representatives of the production department, financial department, brand manager and commercial department.

It is impossible to single out a certain standardized type of jewelry production, as well as one universal jewelry production technology. Any commercial form of jewelry production has the right to exist

from the artel, where everything is done by hand, to high-tech production with a clear division of functionality. Manufacturing technologies for different jewelry items can vary significantly, since the process of creating jewelry uses all modern industrial technologies along with manual processing. Depending on the type of product and its complexity, the most suitable technology for its implementation is selected. The most common are lost wax casting, stamping, turning (most often used in the manufacture of wedding rings), hand or machine chain making, insert cutting, enameling, electroplating, exclusive production. The production involves not only modern domestic equipment, but also Japanese, German and Italian machines.

At all stages of production, after each technological operation, quality control

. To assess the quality of finished products, an industry standard (OST 117-3-002-95) is used, and for control within production, our own quality standards have been developed and used. The company monitors the quality of manufactured products with the help of specialized technical quality control departments and chemical laboratories. There are many quality criteria (color, purity, defects, average weight, quality of inserts, consumer characteristics, etc.), each of which is checked during the process of creating jewelry. Products that do not meet the internal quality standard are considered defective. If a defective product goes on sale, the company takes responsibility and accepts it back within any period after purchase, offering the customer a replacement of the defective product with a new one or a refund of the full cost of the purchased product.

“Jewelry that has passed quality control has a tag, which is a certificate of quality. On the tag you can always find out complete information about the product: number of stones, cut shape, number of facets. For example: “1 Br KR 57 - 2/4”, where 1 Br is the type and number of stones of the size group and these characteristics, KR 57 is a description of the cut (in this case round) and the number of facets, and 2/4 is the characteristics of the stone in accordance with the standard TU 117-4.2009-2002, where 2 is color and 4 is purity. The best clarity for a diamond is 1, and the worst is 12. The number of facets in a diamond reflects how intensely the diamond sparkles. The fewer facets, the cheaper the diamond. The most affordable diamonds are those with 17 facets,” says Nina Sergeeva.

Manufacturability is an important, but not the determining factor in jewelry production,

since, first of all, the aesthetic aspect is more important for jewelry. Particular attention is paid to the environmental friendliness of production and waste disposal, since the waste contains residues of precious metals - they are processed and cleaned several times. If some of the jewelry is not sold, it is sent to sale, where it is often sold at the purchase price. Jewelry production is constantly transforming in line with fashion trends - this can be stated from the point of view of the history of the creation and development of jewelry. It is possible to automate the process of creating jewelry, but the charm and sophistication of jewelry still comes to a greater extent from the skill of the specialists involved in its creation.

Source:

History of the Sunlight SL brand

The SL brand's signature engraving is applied at one of the factories in Hong Kong. A domestic brand is renting a production line from a company from the Middle Kingdom. The choice is justified by the latest high-tech equipment installed at the Chinese plant.

He was assigned class “A” or, more simply, the highest category. Competitive rental prices also play a significant role. Hong Kong belongs to a free zone or, as it is also called, an offshore territory.

In other words, the city has significantly reduced tax rates. This allows you to reduce the cost of Sunlight products without sacrificing quality. The Sunlight brand is the property of Onyx. And this wholesale player in the Russian jewelry market is not interested in tarnishing its good name.

Onyx was registered almost 20 years ago. Sunlight appeared in 2005. Over the 10 years of its existence, the brand has managed to develop connections with four hundred retail representatives.

The number of brand stores in the country this year has exceeded 140. The total number of retail outlets selling products labeled SL is more than a thousand. All regions of the country are covered.

The number of people wishing to become distributors of Sunlight jewelry is growing. This is justified by the high demand for the company’s products and favorable franchising conditions. The brand's franchise is very democratic. To open a point of sale of products with the SL brand name, only about 400 thousand rubles are required.