What is an artificial diamond

Visually, an artificial stone is practically indistinguishable from a natural diamond, except that it is flawless - it has no chips, cracks, or impurities. A charming brilliant specimen - a crystal grown in laboratory conditions that imitate natural ones. A natural diamond, especially of jewelry quality, costs a lot of money, is quite rare, and is available only to a select few. Synthetic specimens are produced in large quantities - sufficient to cover the demand from jewelers and industrialists.

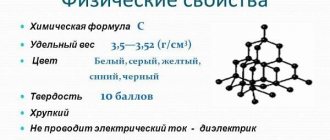

People have learned to grow carbon stones in laboratories, which are identical in hardness, density and optical properties to those formed in the bowels of the earth.

It is difficult to distinguish a laboratory specimen from a natural specimen

Leucosapphire

Leucosapphire is a colorless corundum, often called white sapphire. White sapphires are much cheaper than their blue counterparts and often act as “diamonds” in jewelry in the mid-price segment. They practically do not become cloudy, exhibit outstanding hardness and transparency - in short, a very high-quality and inexpensive imitation.

Synthesizing corundum is much simpler and cheaper than obtaining it from artificial sources, which is why jewelers often work with leucosapphires of artificial origin.

Corundums are a glorious family that includes not only sapphires, but also rubies. These stones are almost identical in properties and chemical composition, with the exception of additives that determine color.

Story

The history of synthetic diamond production began in 1797, when it was discovered that diamonds were made of carbon. At first, it was not possible to repeat the conditions accurately enough and the finished specimens did not have the necessary properties. The first successful experiment was recorded in 1926, but the technical process turned out to be quite complex and required improvements. In 1941, a new experimental series began, but World War II forced researchers to take a break.

In 1954, a breakthrough in the field of growing crystals occurred in Sweden - attempts to create diamonds were finally crowned with success. The laboratory managed to obtain high-quality small crystals that can be used in industry. By 1970, a method for producing large stones was developed and successfully implemented. This is how the synthetic diamond acquired jewelry value.

Over time, scientists learned to obtain in laboratories not only colorless, but also colored crystals. Nowadays blue, red, brown, and golden stones are made. Shades of blue come from boron inclusions, yellow shades come from nitrogen, and pink and brown shades come from distortion of the crystal lattice. Yellow synthetic minerals are easier to obtain than colorless ones, but creating blue ones is a significant challenge.

There are colored and colorless artificial diamonds

cubic zirconia

Chemically, cubic zirconia is cubic zirconium. Cubic zirconia is the development of Soviet scientists who tried to obtain a stone similar to diamond in optical properties, but much less expensive.

They succeeded, and now cubic zirconias are used both in the production of optical equipment and for the manufacture of budget jewelry. Outwardly, they are similar to diamonds, but do not have the same play of color, are much softer and can become cloudy over time. But they are very inexpensive!

Where are they in demand?

It is difficult to distinguish natural from laboratory stones, since scientists create crystals that are identical to natural ones in every way. Most of the produced raw materials go to industry and for scientific purposes. The purest samples are needed for nanotechnology and precision engineering. They are used in the construction of especially durable tools - drills, knives, circles.

Like natural, synthetic stones are in demand in jewelry. Synthetic crystals already account for more than 2% of the diamond market, and this figure is increasing.

Artificial stones are used in industry and jewelry

Industrial Application

Diamond is a stone known for its durability. The invention of synthetic diamond gave the industry new opportunities: laboratory specimens turned out to be harder, more practical, and more uniform. This made it possible to use them as a particularly hard cutting tool, including in the design of units for diamond processing.

Both natural and laboratory diamond have enormous thermal conductivity and low electrical conductivity. Thanks to this combination, the industrial diamond is an advantageous heat sink used in laser diodes and transistors. Thanks to the quality of heat dissipation, electronics last longer and require less repair and replacement. Diamond thermal spreaders are the best way to prevent semiconductor overheating.

Diamond is inert, hard, and slightly expands, so it is suitable for the output window of microwave and infrared radiation. Practice has shown that laboratory diamond is more effective than zinc selenide and silicon.

In electronics, diamond is going to be used as a semiconductor - this area of application is still being researched. Due to the high mobility of electrons, industrial diamond has dielectric properties suitable for transistors. Transistors constructed with diamonds last longer at high temperatures and suffer less from radiation and mechanical wear.

Crystals are needed in industry

Device for working at home

To master the cultivation of precious stones at home, you will need to assemble a device using a Verneuil sample, or purchase a ready-made one. The device must include:

- a mechanism that ensures the gradual flow of substance into the hopper and then into the burner;

- muffle;

- cathetometer;

- 2 separate oxygen and hydrogen supply systems;

- crystal holder and its lowering mechanism.

Depending on the chosen substance, you can grow stones of different colors:

- cobalt oxide - blue and green;

- iron oxide - pink;

- vanadium oxide - green and gray.

The power consumption of the device is about 3 kW. To produce a synthetic ruby weighing 5–6 g, it will take approximately 3 hours, 0.2 g of chromium oxide and 6 g of aluminum oxide powder.

Artificial diamond and imitation are different things

For a layman, these terms often do not differ in meaning, but the difference between them is huge.

It should be remembered that an artificial diamond is a specimen grown in a laboratory and its characteristics are completely identical to a natural mineral. It is cheaper than natural stone, but more expensive than imitation. In terms of strength, hardness, and beauty, it is not inferior to that which appeared in the bowels of the earth.

Imitation is an attempt to make a gem similar to a diamond from another raw material. More often, diamond is imitated with moissanite, and especially cheap fakes are made of glass and even plastic.

Imitation and laboratory stone are different things

Moissanite

Although the name “moissanite” is not equivalent to the term “artificial diamond,” some unscrupulous sellers try to sell this particular stone under the guise of a diamond. The technology for creating moissanite was developed in 1905. The stone is named after the author, consists of silicon carbide and is widely used in industry. In nature, moissanite is found much less frequently; natural samples are inferior in quality to those synthesized in factories. Although quality moissanite is similar to diamond, they are different rocks with different physical and optical properties (as well as price).

Diamonds are often counterfeited

cubic zirconia

Cubic zirconia was made in the USSR in 1968, named after the Physical Institute of the Academy of Sciences. It was developed as a mineral for laser installations. Chemically, cubic zirconia is zirconium dioxide. Outside Russia it is called zirconite or jevolite. The jewelry industry uses large transparent crystals that shimmer beautifully in the light. Although a non-specialist will not visually notice the difference between a diamond and cubic zirconia, do not be deceived - these are different breeds. The optical, physical, and chemical properties of diamond and cubic zirconia differ.

cubic zirconia

Nexus

Nexus is an imitation diamond, named after the manufacturer – Nexus Diamonds. The brand creates beautiful stones, positioning them as family heirlooms that have more status than gems lying on the ground.

Rhinestones

Rhinestones, often Swarovski, are used to imitate diamonds. This is the name of crystal with an improved composition produced by Swarovski. The brand has been operating since the middle of the last century, has its own formula, produces shiny, beautiful crystals.

Swarovski crystals

Comparative characteristics of stones

Externally, it is very difficult to distinguish an artificial gem from a natural one. The imitation has no inclusions or defects, and has the same physical and chemical properties as the original.

But what distinguishes the imitation from the original is the timing and ways of obtaining the gem. Natural stones take millions of years to form in the natural environment, while copies are made in a matter of hours (1–2 mg/h) in laboratories.

You can see the differences using professional equipment. At a magnification of 80 times or more, the granular structure of the synthetic stone is visible. It is also known that they react to magnets. If you place a gem on a white sheet of paper and a white stripe is visible along the edge of the stone, then most likely it is artificial.

In a specialized laboratory, differences can be found using fluorescence analysis, Raman and infrared spectrometry, and spectroscopy.

Special devices have been developed for crystal identification: “DiamondSure” and “DiamondView”.

To continue the topic, watch the video:

Fashion trends

The diamond has attracted people for a long time, which is why it was just as often imitated in the past as it is now. Previously, diamond was replaced with zircon, spinel, crystal, and rutile.

Synthetic stone analogues are an independent area of the jewelry market. The fashion for laboratory samples is growing from year to year in accordance with the ideology of responsible consumption. Since the production of laboratory crystals causes less harm to the environment, more and more buyers want to own such jewelry.

Rhinestones

This group includes a variety of imitations of diamonds created on the basis of glass. It is difficult to confuse an ordinary piece of glass with a noble stone, but jeweler Georg Strass managed to get closer to the ideal, at least visually. He developed a technology for applying metal powder to the glass surface, which made it possible to obtain a spectacular “diamond” shine.

The price of rhinestones varies widely: from a penny for Chinese-made trinkets to very expensive ones for the famous Swarovski crystals. However, the highest quality rhinestone is not even close to a diamond, and it scratches almost like ordinary glass.

Swarovski rhinestones have a unique composition, which is why they are so highly valued in the world. More than a century ago, the maestro developed a technology for the production of artificial crystal, which to this day remains secret and unsurpassed.

Growing techniques

There are several main technologies for producing artificial diamonds. The most common is the creation of a crystal under increased pressure and heating HPHT. This method requires the use of a heavy press. It is cheap to implement, simple and gives high-quality results.

Copying nature

To implement the HPHT technology, a heavy press and a working chamber are used. The object heats up and is under great pressure thanks to the press. The stone blank is placed in the working chamber, and after a week the finished crystal is taken out. The method allows you to obtain cubes and octahedrons.

In a gas environment

Chemical deposition is a method of producing a crystal by depositing carbon from a gas suspension onto a seed. Development of the technology began in the 1980s. The method is flexible, convenient, applicable for small industrial areas, and allows precise control of the chemical composition of the mineral. Thin films are grown on large workpieces in a gas environment. The technology does not require increased pressure.

Making a diamond at home

You can create an artificial diamond yourself. To do this, use olive oil, a couple of cups, 3 graphite rods, and thread. The oil is poured into a container, a thread is laid along the diameter, the graphite is tied with it, the rod is placed on matches or toothpicks, and left for half an hour. After waiting, remove the thread, turn the container over, lay out a couple of clean rods, and oiled one on them. The slates are covered with a second container and placed in the microwave. A diamond is formed in the oiled area. During the process, sparking may occur in the furnace.

You can make an artificial diamond even at home

Organic salts

To synthesize crystals from solutions, organic salts are used as a base. From these substances, called alum, Marc Gaudin obtained ruby crystals. To do this, he fused potassium and aluminum sulfate with potassium chromate.

Using some of the substances, chemistry enthusiasts grow crystals on their own. For example, at home, beautiful bright blue crystalline formations are obtained from copper sulfate . In addition, to independently grow minerals of various colors, you can use:

- potassium chloride;

- inkstone;

- nickel sulfate;

- potassium alum;

- Mohr's salt;

- potassium nitrate and some others.

When choosing a suitable reagent, take into account that it must meet the following requirements:

- dissolve in water or other solvent;

- be stable to temperature increases;

- does not pose a health hazard when used correctly.

The technique for growing crystals from organic salts is based on the preparation of supersaturated solutions followed by crystallization in an open container. The process of obtaining a beautiful “stone” takes more than one month and consists of several key steps.

Preparation of mother liquor

This stage includes a number of actions:

- Pour 700–800 ml of sufficiently hot water, the temperature of which is 50 ℃, into a 1 liter heat-resistant glass.

- Gradually - 1 tablespoon at a time - add the selected substance and mix the composition until the powder is completely dissolved.

- When the solution becomes saturated, that is, the substance stops dissolving, add another 2 tablespoons and leave for 24 hours.

- To prevent foreign particles of dust from getting into the liquid, the container can be covered with a sheet of filter paper.

Obtaining the seed

Includes several steps:

- First, you will need to pour the resulting liquid into a heat-resistant flask, passing it through a filter, and add 1 teaspoon of a substance, which can be the crystals that precipitated in the initial solution.

- In order for the substance to dissolve, it is recommended to heat the container in a water bath at a temperature no higher than 60–70 ℃.

- Rinse a clean container with boiling water so that it heats up to the same temperature as the solution, and pour the liquid into the container.

- Wrap the container in a cloth, such as a towel, cover with filter paper and let cool.

- When the composition becomes cool, small crystals form on the bottom and walls of the glass, from which you need to choose one, which will become the basis of the future “jewel”.

Getting the stone

The single crystal will be grown from the obtained seed:

- The sample you like should be tightly wrapped with thread or fishing line.

- The other end of the thread can be wound around a stick or pencil, which will serve as a support.

- Place the seed in a glass with a solution at room temperature.

- The crystal grows gradually; during this period it cannot be pulled out or turned. If the liquid evaporates, exposing the “stone,” you will need to add more solution.

- After the crystal reaches the desired size, it should be carefully removed and placed on a napkin.

Sometimes grown samples are subject to weathering, that is, they are destroyed by evaporation of the crystallization liquid and turn into powder. They can be preserved in paraffin or under a layer of vegetable oil.

Some experts recommend covering the surface of the crystal with 2 layers of clear varnish

How to choose

When purchasing an artificial diamond, it is important to choose carefully so as not to stumble upon an imitation. During external examination, the shine, purity, and shade of the stone are assessed. Colorless specimens without flaws are preferred. Experts advise checking the stone you like under multiple magnification - this is the only way to make sure that there are no defects. The price of synthetic diamond is 10-15% lower than prices for natural stone.

When choosing an imitation diamond, it is preferable to take moissanite. Its optical and physical parameters are closest to natural stone.

Cost of synthetic crystals

Externally, the original and the imitation are indistinguishable: there are no impurities or defects. The cost for zirconium dioxide starts from 1.5 dollars per 1 carat, moissanite – from 75 dollars per 1 carat. A yellow diamond costs from $200, and a pinkish-orange diamond costs from $3,000 per carat.

Natural diamonds are a resource that will soon run out. According to some reports, the earth has already exhausted the resources for the production of the natural mineral. Therefore, the production of artificial gems is becoming more and more popular.

Did you know about the existence of artificial diamonds? Tell us about your experience in the comments. Share the article with your friends on social networks. All the best.

Main conclusions

- An artificial diamond is obtained from diamonds grown in specially created conditions. The process takes several days. Crystals have a chemical composition similar to natural minerals. Using special technologies, specialists obtain both colorless and colored (pink, yellow, blue) crystals.

- Synthesized diamonds are a valuable raw material for industrial production and jewelry.

- Imitation and artificial diamond are different concepts. Copies of the precious stone are cubic zirconias, moissanites, rhinestones, and nexuses.

- Crystals are grown chemically and physically.

- The cost of a synthetic gem depends on the weight, shade, and cut of the diamond. The pink crystal is considered the most expensive.

- Only an experienced gemologist can distinguish a specimen grown under special conditions from a natural one.

Share your impressions of what you read and leave feedback in the comments.

Interesting Facts

The Guinness Book of Records contains information about the largest diamond created by man. Its size is 34 carats.

At the very end of the twentieth century, chemists obtained diamonds from human and animal remains. Having learned about this technology, many wealthy people preserve the memory of deceased relatives in diamonds. This is how a very profitable business arose.

The largest diamond market is the United States of America (residents of the country purchase more than half of the diamond jewelry in the world).

Scientists in Germany have created artificial crystals from peanut butter, and Mexican chemists have obtained diamond-containing steam from tequila, which can be used to spray a diamond film.

The minerals closest in structure are graphite and diamond. Graphite can turn into diamond and vice versa, but diamond is one of the hardest minerals, and graphite is one of the softest.

Origins of synthesis

Harvard University professor P. Bridgman was at the origins of diamond synthesis. Thanks to his research, it was possible to carry out a “magic transformation” and obtain an artificial mineral from graphite powder. Tracy Hall, a member of the General Electric laboratory research group, was the first to achieve this.

The scientist took part in the development of high-pressure equipment for the production of artificial diamonds. Subsequently, such a system was created and called “halfbelt”. The first experiment was successful on December 16, 1954. It was possible to obtain artificial stone under conditions of increasing pressure to 70,000 atmospheres at a temperature of 1600 °C from graphite and troilite.

Application area

Man-made diamonds (approximately 80 percent) are widely used in industry (glass cutters, drill tips, bearings, spraying of grinding tools and knives), in electronics (for making interlayers in microcircuits), in medicine (using laser technologies, dental treatment ).

The need for this mineral is also explained by the high demand for jewelry (rings, earrings, pendants, bracelets).

Every year the scope of use of this stone expands.