The first gold chains appeared in Ancient Greece and the cultures of Mesopotamia. They were symbols of divine origin, wealth and a sign of belonging to the royal family. Luckily for us, jewelers have been able to make gold jewelry much more affordable.

Gold in its pure form is very soft and has a bright yellow color. To give the desired color and make gold more durable, other metals are always added to it.

To give it a reddish tint, copper is added to it, and with brass, metals melt faster than if gold and copper were melted without it. Depending on the amount in which these metals are mixed into gold, we get an alloy of 14 and 18 carat gold. The mixture is melted in crucibles at a temperature of 1010° C.

The boiling alloy is poured into a casting machine with water, which cools the metal to a temperature of 370°C to harden it. The solidified gold is passed through a circular mold, which is shaped into a 2 meter long pole.

The pole, cut in half, is passed through a crimping rolling mill, bringing it into a square shape, so it will be easier to stretch. The pole is then passed through a tandem mill. The rollers of the machine stretch it to approximately the thickness of spaghetti. At the exit, the rollers twist it into a spiral 24 m long. To soften the metal, the spiral is sent to the oven.

The spiral is unrolled and pulled out again, but to the thickness of the wire, passing it through a mill with industrial diamonds. The gold is doused with a liquid lubricant to protect it from overheating. At the exit we get gold in the form of the thinnest wire. The wire is wound onto a reel. Up to 3 km of wire can be wound on one reel. The coils are unwound and placed in the furnace again, the gold will soften even more.

Specialists at the factory are prohibited from wearing jewelry for safety reasons. At the end of the working day, all workers go through a metal detector, which minimizes any theft.

Venetian weaving of gold chains

Venetian weaving of gold chains is made on a different machine (see video). The wire is placed in a special channel, in which mechanical clamps bend it around the shape, connecting it to the previous link.

To prevent sticking in the subsequent manufacturing stage, the gold chains are coated with powder and heated to 815°C.

The machine attaches locks to each end of the chain, and a stamp is placed indicating the purity of the gold (fineness). The chains are soaked in four tanks of chemicals. They clean the gold from any contamination. Gold chains are coated with a thin layer of gold. That's why they shine so well. After quality control, the finished gold chains are sent to the shelves of jewelry stores.

Stages of chain formation

1. First, pure gold in the form of granules or ingots is melted and combined with a ligature .

These are base metals that give gold its desired purity, color and hardness. For example, copper gives a red tint, and brass gives fusibility. 2. Long wires are made from a mixture of gold and alloy using rollers.

3. In mechanical weaving, the threads are passed through machines that connect metal threads into chains of different types of weaving: “bismarck”, “shell” and “anchor”. The first are considered the strongest, the third are the most popular.

Golden rods

4. The jeweler cuts the finished chains into pieces (chains) and solders locks to the products.

5. At the final stage of work, the chain is polished and, if necessary, diamond edges are applied. This specific cut is called “ diamond ”.

6. White gold chains are placed in galvanic baths, where the process of applying liquid precious metal - rhodium - occurs. It gives the product an additional beautiful shine, and also prevents allergic reactions to the composition of the ligature: silver, copper or tin.

Massive chain

Hand weaving is most valued . Such chains are considered to be as strong as possible. For example, varieties of Bismarck . Everything depends directly on the skill of the jeweler. He makes links from finished wires of the required thickness. Using different methods of soldering each link, he creates different weaves . The easiest way to create a chain is with anchor weaving, but a complex bismarck requires a lot of effort.

Stamping . The sheet of metal is first passed through a press several times. Then the pieces of sheet are cut, and the jeweler continues to work, making links and threading them into each other without soldering. Stamping is a simple method, but such jewelry is easily torn and deformed.

A separate type of chains

hollow ones .

To make them, they use base metal wire, which is removed from the body of the jewelry after a series of chemical processes. A void is formed inside, so earrings, rings and chains turn out to be massive, but quite light. When choosing a pendant for such a chain, you must take into account its weight so that the product does not deform. Creating chains is painstaking and time-consuming work. Before the accessory ends up on the owner’s neck, it travels a long way. And the buyer is left with the most pleasant thing - finding a stylish pendant or cross for the chain on the Zlato.ua website. Choose high-quality jewelry that will make your image harmonious and will delight you for a long time.

Chains with different types of weaving

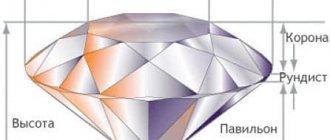

Diamond shape

The armored type of weaving has polished links located in the same plane. Interlocking loops have a rhombic shape and can be connected with one, two or even three links at a time. There are various combinations of armor weave. For example, small links are woven into large ones or sequentially alternate with each other. The first species is called "Nonna", the second - "Figaro". Another weaving method, which can have a square, oval or round cross-section, is called “Snake” or “Cobra”. Indeed, the cord in appearance resembles a snake’s shell and is slightly curved. Rope chain weaving also belongs to the armored type. When connecting the links, the chain rotates slightly in a certain direction, resembling a rope in appearance.

content .. 11 12 18 ..

PREPARATION OF WIRE FROM GOLD AND SILVER

The wire is prepared from gold and silver ingots by drawing them in rollers and ziers. In fig. 1 table II shows ordinary manual wire rollers used in small workshops. The design of the rollers is clear from the drawing. On the surface of the rolls there is a number of parallel grooves, so that holes (streams) are formed between them, which actually serve to pass the metal. Streams are made in various shapes: round, oval, square and others. In large workshops and factories, wire is rolled in several pairs of rolls or, as they say, in several mills driven by a steam engine. First, the piece is rolled in preparatory rollers, in which it is compressed, stretched and, in addition, gradually takes the shape that the wire is desired to have; then rolling continues in other rollers (finishing), having streams of the same shape, but gradually decreasing. Both when machine and manual wire rolling, the following rules must be observed. The ingot to be processed into wire is cast in the form of an oblong bar - a “piece” with a mostly square cross-section; The piece is pre-calcined and forged with a hammer: if the piece is gold, then the forging is done in a cold state, while the silver piece is forged hot. This processing is done in order to give the bite the correct shape and dimensions along its entire length so that it is slightly thicker than the largest hole (stream) in the rolls and, in addition, to blunt sharp edges and corners. In small workshops, which usually only have rollers with monotonous grooves (for example, square), the bit is shaped by hammer forging to match the grooves; then it is calcined and passed through rollers. It should also be noted that the ends of the bite must have the correct shape; if this is not the case, then they need to be sawed off or trimmed; in addition, the end with which the piece is inserted into the rolls should be slightly sharpened, which is done by striking with a hammer. Rolling begins with the largest stream and sequentially passes through all streams to the smallest. Each time a piece is passed, due to the reduction of the strands, it becomes thinner and lengthens, so that a thin wire emerges from the last strand (for example, about 2 millimeters in diameter = 1/10 inch). If they want to obtain even thinner wire, this is done by subjecting it to so-called “drawing” in ziaizen. When successively passing the wire through streams, it must be calcined repeatedly, since otherwise the metal (i.e., gold and silver) becomes hard and the wire may break. After calcination, the gold wire is cooled each time and then put into rolls; silver stretches even when hot. When drawing large pieces into thin wire, the latter comes out to a considerable length (several tens of fathoms), therefore, so that the wire does not take up much space and does not get tangled, it is wound onto drums or reels upon exiting the rollers, thus obtaining the correct skeins. Pulling or “wire drawing” in cyizens using a cybank is also quite simple. Here we will describe a well-designed hand crank (Fig. 2, Table II). A cast-iron or iron board d with a slot in the middle, in which an endless cranked chain moves through two gear wheels c, is mounted on a durable machine; pliers (tsitsangs) c move along the surface of the board d; The pliers, using ring b with hook c, are connected to the chain and when the latter moves in the direction indicated by the arrow, they receive a move in the same direction. The chain is driven by the handle p, while the gear wheels l, m, p rotate; the wheel p captures the chain links with its teeth; racks with serve to strengthen the so-called drawing board, or tsiaizen; One end of the wire is passed through a hole in the ziaisen and grabbed by pliers. Ziaizen - drawing board* is a plate made of solid cast iron or hardened steel. In each cyaizen there are one or more gradually decreasing holes (glasses) of different shapes, for example: square, round, semicircular, star-shaped, etc. In fig. 3 tables II shows a cyaizen with round holes; in fig. 4 shows an enlarged view of the shape of the holes; B-shaped holes are used for pulling the thinnest wire. The wire is inserted into the ziaizen from the widened side of the holes. Ziaizens with ruby glasses are sometimes used; The rubies are drilled and set into copper mounts, which are then set into steel boards. With the help of such ziaizens, a thin, even and homogeneous wire is obtained. After the piece has been passed through all the streams of the rolls and a thin wire has been obtained, the latter can be pulled many times through the smallest holes in the ziaizen and thus bring its diameter to 1 millimeter or even less.

_______________________ * Drawing boards are usually called cast iron or steel plates that have only one hole; Ziaizens are boards with many holes.

You can get thin wire from pieces without using rollers, but using only a cybank and drawing boards. In gimping factories this work is carried out as follows: the cast piece is first forged under a hammer to a known length and thickness; after forging, the piece, to give it the correct rounded shape, is pulled through 3 or 4 holes drilled in thick drawing boards, and then the surface is cleaned of caps and burrs; at this time the bite has a diameter of about 43 millimeters, i.e. about 2 inches; it is then pulled through a series of gradually decreasing holes in the ziaizens, and the piece lengthens and its diameter decreases, and thus a wire of first 15 - 6 mm is obtained, then 3 mm, 1 mm, 1/4 mm and finally 4/100 mm . Wire drawing up to 1 mm thick is done using a steam machine, and thinner than 1 mm can be done manually. To draw a piece with a diameter of 43 mm into a wire of 4/100 mm, it is passed through 111 holes. When drawing both gold and silver wire in ziaizens, it must be calcined several times and after each calcination it must be allowed to cool slowly. The holes in the tsiaizens are lubricated with lard to reduce friction. When drawing wire in a hand-held tsibank, which is usually used in small workshops, one proceeds in this way: first, the piece is forged and given a shape corresponding to the shape of the largest hole in the tsiaisen, and at the same time the thickness of the piece is reduced so much that it is slightly thicker than the largest hole; one end of the bite is then sharpened so that it can be passed through the hole in the ziaizen. Before passing, the piece is heated and, after cooling, the pointed end is inserted into the cyaizen, approved in the cibank, and captured with pincers; put the hook in (Fig. 2, Table P) on an endless chain and set the latter in motion using the handle; the pliers will move along the top board of the tank and pull the wire; when the pliers reach the extreme position, i.e., to the wheel k, stop rotating the handle, remove the hook from the chain, move the pliers to the drawing board, grab the wire here and put the hook back on the endless chain, which is then set in motion, and so on until the piece (or wire) is completely pulled through the tsiaisen. The work, as can be seen from this description, proceeds with interceptions. Then the broach is done through all the other holes of the ziaizen, moving sequentially from larger to smaller until a wire of the required thickness is obtained. From time to time the wire is calcined to give the metal softness. Since holes of different shapes are made in ziaizen, the wire is obtained, depending on your desire: round, semicircular, square, rectangular, star-shaped, etc. You can use ziaizen with holes of the same shape, for example round, to pull wire of different shapes: round, semicircular, type of grooved strip, etc.; To do this, iron or steel inserts (cores) are inserted into the holes of the ziaizen, as shown in Fig. 5 tables I I. By replacing some liners with others, you can get wire of different shapes. Very thin wires (less than 1 millimeter in diameter) are easily pulled through a cyzen and without a cybank; To do this, you only need to strengthen the tsiazen on a workbench or in a vice and then, grabbing the end of the wire passed through the tsiazen with tsitsangs (Fig. 6 of Table II), pull it by hand. For some elegant products and so-called filigree ones, corrugated wire is often required, that is, covered with small depressions (grooves) running along a helical line; such wire is prepared using a special machine called a “cording machine”. In fig. 7 tables It is shown in two views: front and side. Between the plates a a, a gear c rotates with the help of a handle b, meshing with gear d; this latter has a hollow axis, at the end of which there is a cartridge d; the cartridge has a quadrangular notch (socket) into which two dies e e are inserted; so that the dies do not fall out of the socket, a circle is placed on the cartridge and the latter is screwed on; in the dies, cutouts are made in the center, so that when folded together they form a hole for the passage of wire; the walls of this hole are equipped with a screw thread, due to which, if the wire is pulled as shown by the arrow, and at the same time the handle is rotated, then a groove will appear on the wire, running along the helical line. Depending on the thickness of the wire, dies with a larger or smaller hole are inserted. The dies are compressed using screw l. Cordir machines are also used for twisting several wires into one, shaped like a cord; in this case, instead of chuck d, another chuck is placed on the gear axis, in which a hook is fixed on the front side. They attach the wires to the hook and pull them with one hand, while with the other they set the machine in motion: the wires twist and form a lace. The described cording machine is widely used in factories and workshops in Pforzheim in Germany. To obtain shaped wire with complex relief, R. Bruckman with S-mi in Heilbronn in Germany proposed a special device he invented, called “scheidenzangs”, for which invention he took out a patent No. 24726. Scheidenzangs are shown in Fig. 8 tables P (front and side views). In the absence of a detailed description of this device, we will limit ourselves to only the following explanations: the wire is inserted into a bushing in a Scheidenzang and mounted on a lathe; the sleeve at the bottom has a slot into which, when you press the handle p, a knife n enters and cuts the desired shape on the wire. For the same Scheidenzangs, a whole set of knives of different shapes is made and thus, by changing knives, you can get wire of any style. Cutting began from one end of the wire and as cutting progressed, the Scheidenzangs were moved along the length of the wire; The y indicator is used to determine how much the machine needs to be moved so that the cutting comes out correctly. Of course, such scheidenzangs can only be used to trim thick wire (i.e. rods or rods) that can be strengthened and turned on a lathe. Device for determining the thickness of the wire To determine the thickness of the wire, a device called dimass is used (Fig. 9, Table P). It is a round or oblong steel plate about 1/4 inch thick, having a number of drilled cylindrical holes of various diameters, from which slots go to the edges of the plate. The holes are used to measure the thickness of the wire; each of them is indicated by a number; the difference in diameters of two adjacent numbers is 1/10 of a millimeter. The slots are used to measure the thickness of strips and sheets.

content .. 11 12 18 ..

Bismarck chain weaving technology

The main tools for making jewelry are various crossbars, vices, pliers, files and additional materials. At home, knitting needles or any other needles, for example from an umbrella or a bicycle wheel, can be used as crossbars to weave a chain around the neck. A wire is wound around it, forming a spiral. One end needs to be bent in two places, forming a handle, and a cut must be made on the other to secure the wire.

Next, the spiral must be cut into links so that each loop contains two turns. Then the second is screwed into one element using pliers until a characteristic click is heard. In this way, the product is extended to the required length. When weaving a chain, two turns of each link must be compressed to secure it.

To solder the loops you need solder. It is an alloy of various metals in the form of thin plates or wire. Before soldering, you need to take a small piece of solder and melt it with a burner flame. Then move the ball with a soldering iron to the joint of the link, which also needs to be heated, and let it spread. Repeat the procedure with the remaining loops. In the final step, the chain is aligned by pulling it through the rollers.

Weaving method "link to link"

To make a chain with your own hands using this method, you need to prepare links of the desired shape. The main parameter for any weaving is the correspondence of the diameters of the rings and the wire. The thinner the material and the wider the link, the more unreliable the chain becomes. The opposite option creates difficulties in weaving. The rings are made by wrapping wire around the bolt, so it shouldn't be too small either.

The loops threaded alternately into each other should have the same direction. You can solder the ends of the loops both during weaving and after it. When heated, the melting metal should fill the gap at the bite site. In this way, a possible chain break will be eliminated and the rings will be continuous.

How to Wear Gold Chains

True, even a thorough check of the product before purchasing does not give a 100% guarantee of its “indestructibility” if you do not follow the simple rules of wearing jewelry and caring for it. What rules are we talking about?

Wearing a chain without taking it off for many years is not a good idea. Believe me, if suddenly your jewelry breaks for no reason, there is no point in tormenting the Internet with the question of why a gold chain breaks. You, of course, will be given thousands of answers (the main ones indicate the presence of the evil eye or damage to you). But in fact, such a situation cannot be called “out of the blue”! You wore the jewelry without taking it off, slept in it, went to the gym and shower, cleaned the apartment and wandered through the forest - and you never know what else! And so, day after day, year after year, the links in the chain gradually frayed, unable to withstand your “extreme” living conditions. And at first glance, of course, the chain broke “just like that.”

Contact with household chemicals and various detergents and cleaning substances is considered no less harmful for gold jewelry. Gold comes into contact very easily with chlorine, iodine and bromine. Therefore, it is probably a very smart idea to remove the chain before swimming in the pool. And don’t put it on when you decide to refurbish your apartment.

But what won’t harm the chain is reasonable and careful care. It's not complicated! Of course, from time to time you can wash the jewelry yourself in warm soapy water, then rinse in cold water and polish it with a soft cloth. But perhaps a more reasonable solution would be to have your jewelry cleaned by a specialist. He guarantees you that he will use soft, gentle cleaning agents that will not leave even micro-scratches on the product. Still, progress does not stand still, and folk remedies are gradually giving way to professional cleaning. It's probably for the better. At the very least, regular cleaning and preventative maintenance is the key to ensuring that your favorite piece of jewelry will serve you for many years without losing its visual appeal.

Choosing a high-quality, beautiful chain is not an easy task. After all, reliability and aesthetics should be merged in it as harmoniously as possible. Wear jewelry for a long time and comfortably and look your best in it - who can say what is more important today? And is it necessary to choose? Once you learn how gold chains are made, you will be able to choose a product for yourself with greater ease. After all, now all the secret behind the scenes of jewelry production is open to you. We are confident that you will be able to make good use of the information you have!

sea anchor

With the anchor method, the connected links interlock with each other at an angle of 900. The loops of a classic chain have an oval shape. This is the simplest weaving method that you can use to make a chain with your own hands. If there is a crossbar between the links, then the weaving is called “Sea Anchor”. There is a coupling of not only narrow, but also wide rings - rollo or chopard. Venetian weaving differs from classical weaving by links that can take the shape of a square or rectangle. One block can contain several elements.

The magic of hand-made masterpieces

No matter how beautiful factory-made gold jewelry may be, hand-woven chains will always have the status of a unique, aristocratic exclusive. Each such product retains the warmth of the master’s hands and his energy, so do not contact the first jeweler you come across. First, make inquiries about him, find out how the chains he created are worn, whether the fate of their owners has changed for the better or for the worse.

Don't believe in mysticism? Then just look at the samples of chains, evaluate the quality and choose the one whose design you like the most. A jeweler may recommend one or another weave, depending on what purpose the jewelry will serve: to emphasize the seriousness of a business suit, to highlight the luxury of an evening dress, to complement a democratic style of clothing.

You will be surprised, but custom-made hardware chains cost an order of magnitude higher than handmade ones. They are closer to the standards, which means they are more durable and reliable. You can bring your own gold and pay only for the work - very convenient if you have a sufficient amount of scrap gold at home. For each chain, the master selects his own mode of operation of the machine, carefully checking each link so that the chain turns out perfect.

Gold chains presented in jewelry stores are not so expensive due to the highly automated production at manufacturing plants. A streamlined scheme for creating chains allows you to reduce the time spent on weaving and, accordingly, reduce the cost of the product. By the way, large jewelry stores provide the opportunity to exchange gold scrap for a finished product, paying extra only for the work and the missing grams.

Before purchasing a chain, check it for smoothness and absence of burrs, make sure that it has a sample and the manufacturer's mark, and test the strength of the lock. We hope that your new gold jewelry, regardless of who made it - a person or a machine, will delight you for many years.

What you will need

Of course, you need golden beads. You will need about 5 grams of it. The more beads, the longer the chain will be. From 5 g of beads you get a chain 46 cm long. You also need to have on hand:

- fastening from some old unnecessary chain;

- igloo;

- thread for weaving beads.

Being woven on a thread, the finished chain will turn out thin and elegant, well imitating gold. If you don’t have a special thread, you can use thin fishing line instead. In this case, the chain will be more rigid, but will also look impressive. It is better to take smaller beads for weaving the product. Then the chain will look more impressive.

The history of ancient jewelry

Today we do not know for certain where the craftsman who first came up with the idea of making links from precious metal and connecting them together lived. It is unknown what his name was. One thing is certain: this happened a very, very long time ago. After all, fashionable gold chains first appeared at almost the same time in Ancient Greece and Ancient Egypt. True, at that time, only a massive chain, which only very wealthy men could afford, was considered “fashionable” at that time.

It is believed that sun worshipers decorated themselves with items made of yellow metal to respect the deity and become like him. And noble citizens of Greece and Egypt, as evidenced by excavations, were always buried in full vestment: it included, among other things, the heaviest gold chains.

As time passed, representatives of the fair half of humanity chose “male” jewelry. Then the stylish gold chain became much thinner and lighter and, in general, came closer to the look that we know now. At the same time, the girls’ imagination ran wild, and women’s chains began to be worn not only as a separate piece of jewelry, but also as a basis for a pendant. And besides, such an accessory began to be worn not only on the neck, but also on the arm, leg, and even woven into the hairstyle.

Our closest ancestors also had their own chest decorations. For example, until the 13th century in Rus' it was fashionable to decorate oneself with so-called “pendants”. This was the name for amulets made of metal or stone, which were suspended on a chain.

Interestingly, the fashion for a particular link shape was very variable. And only after a long time were the most popular geometric shapes from which chain links were made determined. These were:

- rings;

- ovals;

- squares;

- diamonds.

The question of how to make chains was simply not asked then: only by hand. Of course, our ancient ancestor did not yet know any machines or mechanisms, and therefore each piece of jewelry was made by a goldsmith - a chain maker. This is also why the chain was perceived as a very expensive accessory. Very few could afford to pay the cost of the precious metal and the services of a chain maker, so in the Middle Ages such jewelry remained an unchanged symbol of wealth and high position in society.

As often happens, machine labor is valued much less than manual labor. And therefore, the advent of chain knitting machines partially solved the problem of the exorbitant cost of gold jewelry.

France was the first country in which machine chain knitting was put on stream. During the French Revolution (and this is the end of the 18th century), a machine for weaving chains was first manufactured. It greatly simplified the production of jewelry and made it cheaper. It’s interesting that the basis for the first machine was… a sewing machine. Specialists sought to make the machine repeat the movements of a person, a master, only, of course, doing it faster and more perfectly.

Over time, companies appeared that specialized in the manufacture of such chain knitting machines. The business became profitable, and everyone benefited: machine tool manufacturers, jewelers, and end consumers.

Availability and prestige

Actually, only in the middle of the last century did gold jewelry become available to many people. A variety of accessories made from the main precious metal decorated the images of fashionistas and fashionistas. And although today gold chains are deprived of the status that they had ten centuries ago, they still remain a prestigious and sought-after decoration. There may be several reasons for this.

- Symbolism of the circle. No matter how modern people we consider ourselves to be, somewhere deep in the subconscious many people still believe in signs that were important to our distant ancestors. The circle in the minds of the ancients is a symbol of the ideal and the most powerful amulet. And the chain consists of many small circles-links that wrap around the neck in a large circle. The chain is therefore a protection. Albeit on a subconscious level.

- Symbolism of the gold metal. Gold is a symbol of the Sun. Remember how often in winter or on cloudy days we lack the warmth and light of our sun. Gold, the “representative of the Sun on Earth,” can replenish the lack of energy in the body, recharge you and give you optimism and success.

- Versatility. There is no person who would not like a gold chain. There are simply no such people. Thin, thick, simple, fancy, short, long - the choice is truly endless.

- Compatibility. This accessory looks great on a person of any gender, age, build, or social status. The chain advantageously sets off dark and pale skin, light or dark hair, blue or brown eyes. And most importantly, it goes perfectly with any clothes - without exception!

- Durability. Provided you purchase a quality product and use it carefully, the chain will serve faithfully not only to you, but to your children and grandchildren. Least.