/ List of stones / How to distinguish synthetic sapphire from real one

0

5730

Article rating

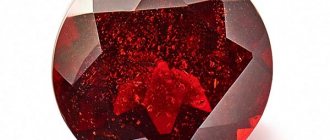

Synthetic sapphire is one of the most popular artificial gemstones. The most in demand products are cornflower blue, which delight and attract the eye. Being an analogue of natural stone in its physicochemical and optical properties, in some ways it even surpasses it.

Synthetic sapphire

Characteristics of artificial sapphire

In nature, precious sapphire is a mineral of the oxide class, a type of corundum of blue and dark blue color. It is a hard, fascinating and rare stone, which leads to its high price. The cost of laboratory analogues is lower, and that is why its imitation is so popular, which only a specialist can distinguish from the real thing. Modern technologies make it possible to bring any saturation to its color.

Synthetic sapphire is not much different from natural sapphire. There is no need to confuse diffusion stone with it, which is fundamentally different from artificial stone - diffusion stone is not grown from scratch, but is only processed in a similar way.

Popularity in the world

The cost of artificial sapphires directly depends on the quality and size, and synthesis allows you to achieve any crystal parameters, and the equipment for its growth is constantly improving and becoming cheaper. In terms of its properties, man-made corundum is as close as possible to the original from the bowels of the planet. The synthesis product, like an ordinary mineral, has no chips, cracks, or other damage. This attracts jewelers and consumers of such products, who prefer to insert these durable stones into their gold earrings.

Stone analogues

A real good quality sapphire is an expensive gem, so criminals promote many types of fakes on the market:

- The most primitive imitations are made of glass . They even use simple bottled ones.

- Doublets, triplets . These fakes consist of two or three layers glued together. One part is sometimes made of natural sapphire, the other is made of a synthetic crystal, glass, or a corundum-like mineral. The suspicious area is often hidden behind the frame.

- Instead of sapphire, they sell cheaper stones , for example, low-grade spinel, tourmaline, kyanite, tanzanite, cordierite. The worse the quality of corundum, the more other gems are suitable for its imitation.

- Synthetic sapphires . Scientists receive them officially. Sapphire glass is used, for example, in aircraft manufacturing and watches from well-known companies. As a rule, Verneuil technology is used to obtain stones. They take corundum chips, iron, titanium, chrome. Nickel, cobalt, magnesium, and vanadium are added for coloring.

Manufacturing

Artificial is synonymous with fake, but in the case of a stone synthesized in a laboratory, this is not at all the case. Some even consider it a complete analogue, since the manufacturing process almost repeats the natural one, taking place in the magmatic conditions of the subsoil for hundreds of thousands of years. You need to understand that the growing process is similar to natural processes of formation in almost everything except speed. For production, aluminum oxide and various impurities are used in the ratio necessary to achieve the goal.

The most popular alloy is titanium, which produces a purple hue, but chromium, manganese, iron and vanadium are also often used. In the popular hydrothermal manufacturing method, seed plates with a solution are processed under pressure at temperatures from 300 to 5000°C.

There are other methods for growing synthetic sapphires, but the first and classic one is Varneuil's method, who came up with the idea of exposing iron oxide to a gas burner with hydrogen and oxygen. With a burner this can be done even at home.

How crystals are grown

There are several main methods by which synthetic sapphire is grown. For a long time, manufacturers acted according to the Verneuil method, which consisted of several stages:

- Powdered alumina with additions of titanium and iron oxides was placed inside a special hermetically sealed burner with a ceramic muffle.

- Heating occurred at high temperatures and pressure, accompanied by melting of the powder and then settling on the pin.

- The growth of a conical-elongated boule (growth) began.

To grow higher quality artificial sapphire, the alumina powder must be fine-grained, dry, and able to “flow” easily. If the grains are large, then the viscosity of individual sections increases, which leads to distortion of the shape of the boule and deterioration of its internal structure. This is how they even learned to produce specimens with the asterism effect.

The second method of growing sapphires artificially is hydrothermal. Its essence is as follows.

- Instead of powder, a seed of natural colorless corundum is used. It is very small, but it is on it that the crystal grows.

- Next, a saturated solution is prepared containing aluminum ions, as well as chromophoric elements (“dyes”). The seed is lowered into it.

- The starting materials are placed in a special autoclave, which is capable of maintaining high temperatures (300-600 ℃) and pressure (up to 1.5 Kbar).

- As a result, conditions similar to natural ones are created. The growth of a synthetic (“cultured”) crystal begins from the solution on the seed.

The resulting material is of high quality: transparent, evenly colored, but including the smallest bubbles. They are characteristic of this technology, although they practically do not affect the purity of the stone.

The third method is the Czochralski method, which is based on “pulling” a substance from a melt placed in a refractory crucible. The seed, lowered into the melt, gradually rises, and sapphire is deposited around it.

At temperatures above 1750℃, diffusion treatment of the grown raw materials with iron and titanium is applied to obtain a blue color. Beryllium gives other shades to the crystal, for example yellow.

Best Ways to Distinguish

Sapphire jewelry

Natural and synthetic sapphires can be distinguished from each other if you are extremely careful. Artificial sapphire is not a fake. It would be possible to call it that if it only looked like a sapphire, like a well-made piece of glass. But here there is almost complete compliance with the chemical and physical properties of the natural analogue. It looks like the real thing and is close in properties, but there are still some nuances. Grown ones have incorrect growth microstructure.

Sapphires of natural and artificial origin differ from each other in hardness. Natural stone takes second place in this indicator. Sapphire, mined from the earth, is capable of scratching any other stone except ruby and tungsten carbide. Artificial crystals are not as hard.

Visual cues

It is possible to distinguish natural sapphire from synthetic one by external signs.

- The most visible difference is that the artificial mineral is more flawless and pure in color.

- There are no defects or various inclusions such as feather-shaped crystals, liquid formations or black voids.

- Under a magnifying glass, regular spherical bubbles are visible, which in natural stone have an irregular shape.

Mechanical ways of distinguishing

Special equipment will help you understand that it will be a synthetic sapphire.

- Measurement with a refractometer: the refractive index of light for real minerals is 1.762 - 1.778.

- The object is placed in monobromonaphthalene immersion liquid, the container is placed against the background of a white sheet. If the colored stripes on the sheet are not straight, but curved, this is a grown mineral.

- Under short-wave ultraviolet light, a real sample will not change color, but a produced sample will glow either whitish or dirty green - if there is an admixture of titanium, and sometimes red.

Properties and Application

The chemical properties of nano sapphire are practically no different from the original ones. The main structural element of corundum is aluminum oxide. The physical characteristics are also unchanged: hardness 9 out of 10 on the Mohs scale, density almost 4 g/cm3. Interacts with acids and dissolves in them. It has a glassy luster and a melting point of over 2000℃. This means that hydrothermal sapphire is no worse than natural sapphire. But the price is much more affordable.

The main area of application is the jewelry industry. However, other areas of industry also need artificial minerals: the aircraft industry, construction, the manufacture of magnifying instruments, cameras, collectible watches, etc.

Useful tips

You should choose jewelry with sapphires based on your own preferences and financial capabilities. Those who believe in the magical and healing properties of stones should purchase real gems. It is believed that only they have supernatural powers. When purchasing natural stone, you should ask the seller for documents confirming its authenticity.

People who value, above all, an attractive appearance and the absence of flaws in stones, are more suitable for artificial sapphires. Purchasing jewelry with such corundum is a good option for those who want to save money.

Post-cultivation treatment

To prevent cracking, the resulting sapphires are subjected to post-growth annealing in special installations. Subsequently, they are given the desired shape using laser grinding and polishing with suspensions and pastes. Due to the fragility of the material, processing using lathes, drilling and grinding machines is not used.

Synthetic sapphires are colored and refined using various technologies: diffuse treatment with metal salts, heating, and ultraviolet irradiation.

First attempts at synthesis

Synthetic sapphire was first obtained by the French chemist Verneuil in 1904. To do this, he used a method he himself invented: he placed the finely ground mixture in the flame of a hydrogen burner. Verneuil's method quickly found wide application and is still used almost unchanged today. But it's not perfect, so the experiments continued.

In 1916, Polish chemist Jan Czochralski came up with a method for growing crystals from a melt. According to legend, he dropped a pen into a crucible of molten tin, and when he took it out, he noticed that a thin thread of hardened metal was trailing behind the pen. It turned out that it has a monocrystalline structure. The chemist developed a method for the synthesis of other single crystals, which was later called the Czochralski method.

The first hydrothermal sapphire was created almost 60 years ago by two researchers - Laudise and Balman. They managed to obtain a high quality colorless stone. And several decades later, scientists from Novosibirsk selected a dopant based on divalent nickel, achieving a uniform “sky blue” color of sapphire. Since 1995, the technology began to be used for industrial purposes, and was later supplemented and expanded.

From calculation to breakthrough

PKF Atlas LLC changed its sign to Belgorodsky LLC, and Hovsepyan worked there for six months. When launching Techsapphire LLC, he already knew how to build business processes. While still living in Armenia, in 1995–1997. Martik Hovsepyan owned a small production facility - he supplied sapphire blanks for watch glasses to South Korea. Techsapphire was born in 2008, when the market for sapphire substrates, which are used in the mass production of LEDs and microcircuits, began to grow. “The demand for sapphires has grown significantly, but production has not kept pace with such demand,” adds Hovsepyan. “This has led to an increase in prices for LED substrates by 3-4 times.”

However, of all types of production, he chose almost the most difficult one - the design and sale of electric furnaces for growing crystals. The success of such a project depends on the availability of its own premises and two sources of electricity in case of force majeure. If land can be rented, there is no point in engaging in this type of business without a separate substation. “A power outage even for a couple of minutes causes huge losses. You can lose products that have been growing for a couple of weeks before,” explains Hovsepyan. He spent a long time looking for the right place to start in the Belgorod region. He was lucky: in 2008, construction began in the village of Severny on a joint project between the region and the Russian government - the Severny industrial park. “In the beginning, there were few people who wanted to become residents,” says Hovsepyan. “The green field without a single building was intimidating.”

In 2009, 600 sq. m. were built to meet the technical requirements of Techsapphire LLC. m of premises, carried out the necessary communications and launched a small electrical substation. When Hovsepyan left the Belgorod division of Monocrystal, part of the team left behind him, and he hired two specialists from outside. The five engineers started from scratch - they made a couple of installations and launched an experimental workshop for growing crystals. At the start, about 30 million rubles were invested in the company. Part of the amount came from Hovsepyan’s personal savings, several million rubles were lent by entrepreneurial friends, and the missing 17 million rubles. I had to take out a loan. The project paid for itself in 1.5–2 years of work - after gaining capacity, Techsapphire produced up to 10 furnaces per month. In two years, the company sold more than a hundred devices to Korea, China and Taiwan. “We repaid our debts and began to buy out the production facilities leased to us,” says Martik Hovsepyan. 2011 marked the peak of the company's prosperity - the staff increased to 100 employees, and the turnover amounted to more than 380 million rubles.