If handled carelessly, silver chains often break. And then the problem arises of restoring the integrity of your favorite jewelry. Of course, you can turn to a jewelry workshop for help. But such repairs require additional costs and are not always convenient due to time or other circumstances. In addition, the procedure for connecting broken links is simple, and you can do it yourself. The article will discuss how to solder a silver chain with your own hands at home.

Soldering with silver requires a certain skill, knowledge of the physical and chemical properties of the material and the presence of some tools and components for its implementation.

Features of silver soldering

The melting point of pure metal is 960 degrees Celsius. Household soldering irons, even the most powerful ones, do not heat up above 400 ºС. Therefore, a material containing several components is used as solder, one of which is silver. And to heat the parts being connected, soldering gas torches are used, capable of heating up to 850 degrees. The alloy must match the product in color, but at the same time be subject to melting at a lower temperature. The best aesthetic effect will be ensured by using solder that matches the composition of the one specified for the sample of the product.

We solder chains, bracelets and spoons

A chain or bracelet breaks for several reasons - the metal has worn out over time, you got caught on something. Or the pendant was too heavy for the chain. A spoon breaks - from old age, from a fall, or because the master made mistakes during its production.

Prices

| METAL JEWELRY, PRESENCE OF INSERTS | SILVER | GOLD | WITH ROCKS |

| Soldering of domestic chain | from 150 ₽ | from 250 ₽ | |

| Soldering of imported chain | from 250 ₽ | from 300 ₽ | |

| Soldering hollow chains, bracelets | from 250 ₽ | from 350 ₽ | from 600 ₽ |

| Soldering of hollow chains, bracelets with pin replacement | from 400 ₽ | from 900 ₽ | from 1000 ₽ |

| Soldering spoons | from 600 ₽ | from 1600 ₽ | from 2000 ₽ |

What does the price depend on?

The price depends on the complexity of the master’s work. From the type and standard of the metal of the product, the presence of inserts, fasteners and engravings, from the amount of solder that will be used for welding. The price will rise if additional services are needed - cleaning the jewelry, restoring the coating, or changing the clasps on chains or bracelets.

Chains and bracelets

If several links of a chain are broken or stretched at once, the craftsman will spend more time and solder restoring the product - check with the craftsman about the timing.

If the chain is very thin, it is important for the master to correctly distribute the solder on it so that it does not spread and flood the adjacent links and spoil them - this is a difficult job, it requires the special attention of the master.

If a hollow chain or bracelet breaks, the jeweler fills the damaged link with solder or makes and inserts special pins inside to assemble the jewelry. In this case, the complexity of the master’s work is higher.

If the jewelry has gilding, rhodium or blackening, when hot soldering, this coating will peel off from the entire product. To prevent this from happening, we use laser soldering.

If a chain or bracelet contains precious stones, in order not to damage them, the master works with a microscope - this increases the cost of repairs. Emerald, sapphire and ruby cannot withstand heat from open flames during soldering and become discolored. To prevent this from happening, we use laser soldering, which is more expensive.

Domestic gold jewelry has 585 metal standard and standard colors: red, yellow and white. We make solder for each color of the product; we always have it in stock. European gold jewelry comes in a different standard (750, 375, etc.) and colors: lemon yellow, light yellow, green. Solder for 585 test is not suitable for such products - traces of soldering will be visible. To prevent this from happening, we make individual solder for each foreign jewelry. Therefore, repairing imported chains and bracelets is more expensive.

When a jeweler solders a product, it heats up entirely. If there is a lock at the end of the product, the spring inside often cannot withstand the heat and breaks. To prevent this from happening, the jeweler removes the locks and puts them back on after soldering. This is an additional service if needed.

Attention. Sometimes repairs are not practical. This happens if the decoration is damaged along its entire length. Or there are so many broken links that once the jeweler removes them, the piece becomes too short to wear. Or if the chain is too worn and is often in repair, then after fixing one ring, another may soon fall apart. We will offer to scrap such chains in order to make a new decoration from this metal for you.

Spoons

If the spoon is pre-revolutionary or the foundry worker violated the technology during production, there may be pores inside the product. These are empty cavities that become visible when the jeweler has already heated the soldering spoon. In order to fill these voids, the craftsman needs more solder, as well as time to work.

If there is enamel or precious stones on the spoon, in order not to damage the elements of the product, laser soldering is needed, the price for it is slightly higher, and at the same time the type of product is more expensive. If there is an engraving on the item, the jeweler will restore it after welding.

If the spoon had previously been repaired by another craftsman, he could use tin to repair it. When heated, tin spreads and “eats” the precious metal from which the product is made. It is difficult for a jeweler to work with such a spoon, so check the working time with the master.

The thickness of the spoon is about 3-4 mm, and the width, depending on the location of the break, is up to 10 - this is a massive product for a jeweler. To boil a piece of cutlery, it takes a craftsman several hours of work and a large amount of solder. The wider and thicker the surface that needs to be restored, the higher the price.

Our guarantees

We provide a 1 year warranty on the product.

All jewelers have higher specialized education. The work experience of the craftsmen ranges from 8 to 40 years.

All items we repair are inspected before being returned to you (there will be a link to the inspection at this point). It guarantees that the decoration or cutlery after repair in our workshop will be free of defects and will not break.

Deadlines

The master will repair a simple chain or bracelet in 5 minutes in your presence. You can put the jewelry on right away and leave in it, it will be like new. Repairing the spoon will take 20 minutes. The spoon can be used the same day. If the product is complex (with stones, enamel, engraving), the jeweler will inform you about the production time of the product. On average, such repairs take one day.

How to order?

Call our specialist by phone or write to WhatsApp and Viber at +79052228878, he will advise you specifically on your product and will be able to make a preliminary assessment of the work.

How does soldering of silver products occur?

Before repairing a broken chain, the parts to be connected must be degreased. To do this, the flux is diluted with water and the resulting slurry is applied directly to the rupture sites. The product is installed on a fireproof base and is well fixed. Such precautions help to avoid deformation of the chain during operation.

Using wire cutters, cut a piece of solder to the required size and place it at the site of the intended welding. The burner is brought to the side of the product and the joint is evenly heated. The intensity of the gas jet should not disturb the location of the flux and solder. After the degreasing component has melted, the flame force is increased to form a solder joint. If the amount of solder is not enough, use tweezers to add a suitable piece and continue working.

After cooling, the product must be cleaned of flux residues. To do this, use an acid solution or liver sulfur (a mixture of sulfur and potash).

Why do silver chains break? Top 3 reasons

- Defective product. But the store will not simply accept a broken chain back: an examination must be carried out to prove a manufacturing defect. If the examination confirms that the manufacturer is at fault, then the buyer will return the money spent - both for the decoration and for the examination.

- Hollowness. Yes, chains are often made hollow - this is not very practical, but it reduces the cost of decoration. Heavy pendants cannot be hung on such chains, and they can also break from the slightest mechanical impact.

- Wearing heavy pendants. To avoid putting too much stress on the chain, consider the weight ratio of the chain to the pendant.

Using a soldering iron

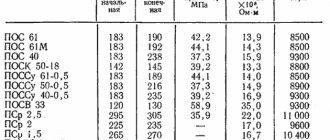

Methods for repairing silver items at home are not limited to the method using a gas torch. To repair small cracks, you can use POS-60 solder, which has a melting point of 180 degrees. It is produced and sold in the form of tubes filled with resin. The latter is used instead of flux in conventional soldering. The same solder is used when repairing electronic circuits. This area must be degreased with a colony, which will also play the role of protection from the negative effects of ambient air during heating. The area to be repaired is heated well and a piece of solder is placed in it. Using a soldering iron, maintain the desired temperature until it completely melts and joins the parts.

How to solder a product: basic methods

At home, you can use one of two soldering options applicable for silver:

1. Gas burner. This method is not only simple, but also cost-effective. You need to proceed as follows:

- Clean the entire surface of the parts being soldered from visible dirt and blackness;

- Apply a thin layer of flux to the elements. You can cook it yourself. To do this, borax is poured with water and heated in a water bath. The mixture is cooled, and the resulting crystals are crushed in a mortar.

At home, you should avoid formulations that contain cadmium elements. Its vapors can lead to poisoning.

- Place a pre-prepared piece of solder at the soldering site. It can be cut with wire cutters;

- Use a gas burner to heat the product from its side, paying attention to the position of the solder. It should not be blown away by the flame;

- As the flux melts, the flame should be increased until the solder forms a seam. If there are insufficient materials, they can be added during work;

- After soldering is completed, allow the product to cool and wipe all parts of the item being soldered at the junction with sandpaper to remove traces of flux. It will also remove excess solder.

When soldering silver items, it is better not to use tin and lead solder. It will help out in an emergency, but in the future it will complicate the connection of the jewelry in the places where it was used. And part of the chain will have to be cut out. The same point should be clarified in jewelry workshops if the choice turned out to be in their favor.

2. Soldering iron. To solder parts of a product with a soldering iron, you should choose a device with a thin tip. It is better to buy POS-60 solder for such work. It begins to melt at a temperature of 180 degrees.

You may be interested in: Gold bracelet for watches: review, choice

This solder is somewhat different from the usual types. It is made in the form of a tube, the inside of which is filled with resin. It is this that is an alternative to borax flux and performs the function of protecting the alloy from possible oxidation. The procedure will be as follows:

- The surface of the product is cleaned from oxides and other contaminants;

- The joints are heated to such a temperature that it becomes above the melting point;

- Solder with flux embedded in it is placed at the melting site;

- The surface of the product is heated with a soldering iron. Under the influence of high temperature, the solder begins to melt and spread evenly over the surface;

- The product is allowed to cool and the joints are cleaned with sandpaper.

When working with a torch and a soldering iron, you must take precautions, since both devices can cause a fire.

It is important to understand that any poor-quality work can ruin the product. Therefore, if possible, it is better to entrust a broken chain or other silver jewelry to professionals.

Precautionary measures

Working with solders can be hazardous to health and therefore requires compliance with safety precautions. The procedure should be carried out in a well-ventilated area. While working, you must wear protective clothing and gloves. When performing direct soldering, use safety glasses or a mask. Heated parts and materials are held with tongs at a safe distance from the face. After working with flux, hands should be washed thoroughly, as even a small amount of this substance, if swallowed, can cause serious harm to health. For this reason, smoking is strictly prohibited during soldering. If your health worsens after soldering silver items, you should immediately consult a doctor.

Practical advice

Almost every day people come to various jewelry stores with the question of where gold chains are repaired, as well as where they can buy clasps and links for various products. This fact indicates that the jewelry is quite fragile and can break if handled carelessly. Nowadays, girls very often wear thin jewelry, which can break if it gets caught on some object.

gold chain

If your gold, silver or other metal chain breaks, take it to a workshop. Modern jewelry makers use the latest technology to repair jewelry. This allows you to make the product the same as it was before it was torn.

If your chain is broken, do not despair, but follow our advice on how to behave in such a situation:

- First of all, you need to calm down and remember that repairing jewelry is a fairly quick and simple matter;

- Try to place all the pieces of decoration in a tightly sealed bag so as not to lose the pieces;

- Find out where jewelry repairs are done in your city;

- Give the product to the workshop for repair, having previously discussed the cost of the work;

- Pick up your jewelry from the master at the appointed time.